A kind of production method and application of calcium aluminate cement clinker and alumina cement clinker

A technology of calcium aluminate cement and production method, applied in the field of preparation of calcium aluminate cement clinker or aluminate binder, can solve the problems of poor quality, inhomogeneous and stable ore phase of calcium aluminate cement and the like, and achieve short time interval , The effect of reducing the fluctuation of the sintering process and the long initial setting time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

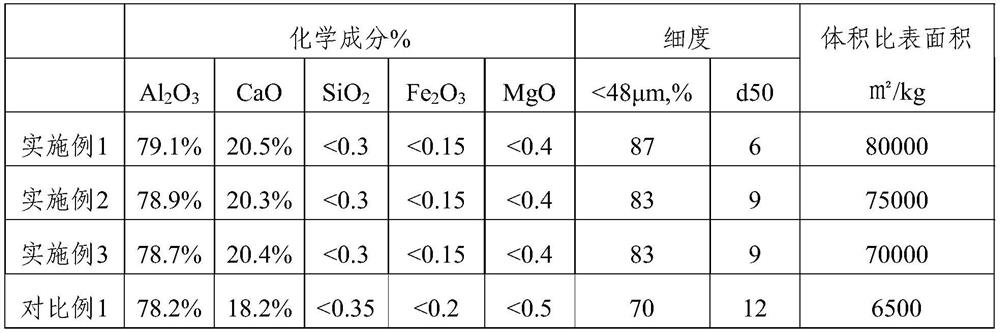

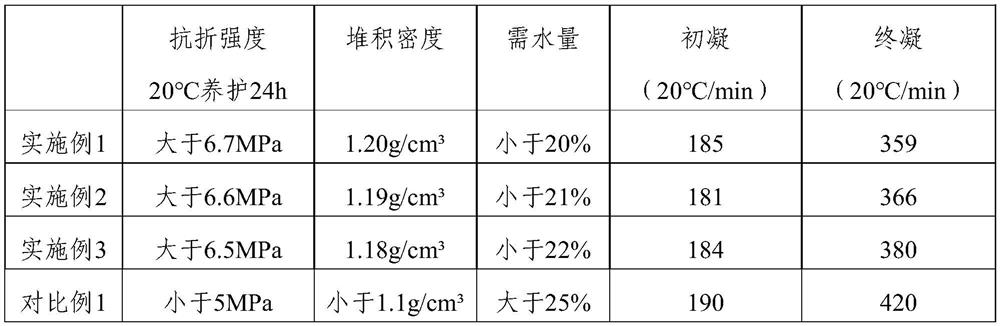

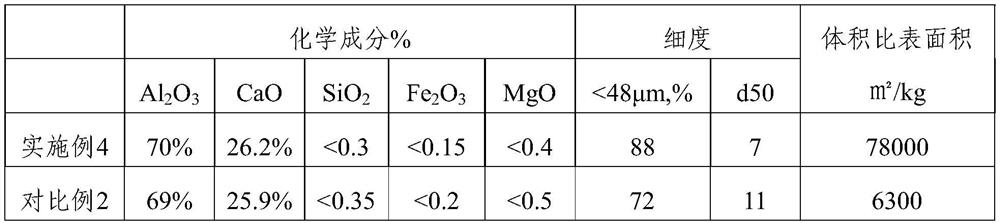

[0062] Example 1 CA-80 series calcium aluminate cement clinker

[0063] The present embodiment provides a production method of CA-80 series calcium aluminate cement, comprising the following steps:

[0064] (1) Wet ball milling mud:

[0065] Add 80kg of alumina, 20kg of calcium oxide and 100kg of water into a wet ball mill, and grind for 15 hours to obtain a slurry with a mesh size of 200-400 and a solid content of 78%-80%.

[0066] (2) Homogenization treatment:

[0067] The obtained slurry is input into the mud pool for filtration and homogenization treatment, specifically: use multiple mud pools to store and filter the mud, and simultaneously transport the filtered mud to the filter cloth machine through the plunger pump, and homogenize and mix while transporting;

[0068] After the homogenization treatment, the moisture content of the slurry is controlled at about 45%, and the uniformity reaches a difference of less than 5% per cubic centimeter of moisture content;

[00...

Embodiment 2

[0081] Example 2 CA-80 series calcium aluminate cement clinker

[0082] The present embodiment provides a production method of CA-80 series calcium aluminate cement, comprising the following steps:

[0083] (1) Wet ball milling mud:

[0084] Put 78kg of alumina, 20kg of calcium oxide, and 90kg of water into a wet ball mill and grind for 16 hours to obtain 200-400 mesh slurry with a solid content of 75%.

[0085] (2) Homogenization treatment:

[0086] The obtained slurry is input into the mud pool for filtration and homogenization treatment, specifically: use multiple mud pools to store and filter the mud, and simultaneously transport the filtered mud to the filter cloth machine through the plunger pump, and homogenize and mix while transporting;

[0087] After the homogenization treatment, the moisture content of the slurry is controlled at about 45%, and the uniformity reaches a difference of less than 5% per cubic centimeter of moisture content;

[0088] Among them, the p...

Embodiment 3

[0100] Example 3 CA-80 series calcium aluminate cement clinker

[0101] The present embodiment provides a production method of CA-80 series calcium aluminate cement, comprising the following steps:

[0102] (1) Wet ball milling mud:

[0103] Add 79kg of alumina, 20kg of calcium oxide, and 90kg of water into a wet ball mill and grind for 24 hours to obtain a 200-400 mesh slurry with a solid content of about 70%.

[0104] (2) Homogenization treatment:

[0105] The obtained slurry is input into the mud pool for filtration and homogenization treatment, specifically: use multiple mud pools to store and filter the mud, and simultaneously transport the filtered mud to the filter cloth machine through the plunger pump, and homogenize and mix while transporting;

[0106] After the homogenization treatment, the moisture content of the slurry is controlled at about 45%, and the uniformity reaches a difference of less than 5% per cubic centimeter of moisture content;

[0107] Among the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com