A microwave vacuum sintering method for ultra-fine-grain cemented carbide, and cemented carbide products

A cemented carbide and microwave vacuum technology, which is applied in the field of cemented carbide manufacturing, can solve the problem of microwave sintering of ultra-fine-grained cemented carbide, difficulty in obtaining ultra-fine-grained cemented carbide, long sintering time and holding time, etc. problems, to achieve the effect of fine and uniform metallographic microstructure, uniform distribution of cobalt phase and good wear resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

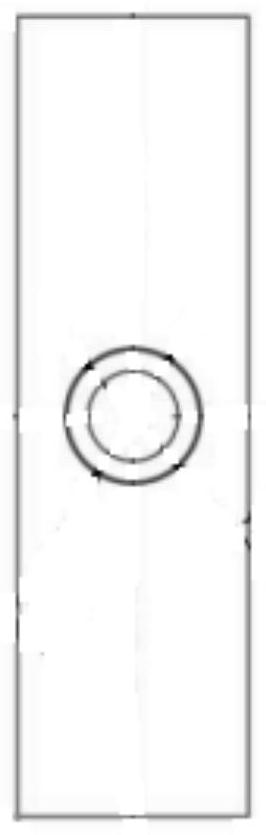

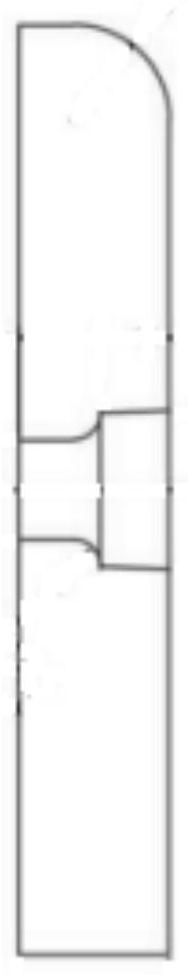

Image

Examples

Embodiment 1

[0080] A microwave vacuum sintering method for ultra-fine-grain cemented carbide, comprising the following steps:

[0081] (1) The cemented carbide is an ultra-fine-grained cemented carbide, and the mass percent of its components is: WC powder 88, Co powder 12%, wherein the WC Fischer particle size is 0.3~0.4 microns, and the Co powder Fischer particle size 0.6 to 1.0 microns.

[0082] (2) The raw materials are mixed in proportion, ball milled, mixed with paraffin molding agent and pressed into shape, and then put into a microwave vacuum sintering furnace for sintering.

[0083] (3) The microwave vacuum sintering furnace is produced intermittently, with a total power of 100 kilowatts. The microwave power is continuously adjustable. The microwave frequency is 2450 MHz. Vacuum protection or inert gas is used. Air-cooled rapid cooling cooling.

[0084] (4) The sintering process is divided into four stages: inert gas positive pressure dewaxing, vacuum degassing solid-phase sinte...

Embodiment 2

[0092] A microwave vacuum sintering method for ultra-fine-grain cemented carbide, comprising the following steps:

[0093] (1) The cemented carbide is an ultra-fine-grain cemented carbide, and the mass percent of its components is: WC powder 88%, Co powder 12%, wherein WC Fisherman's grain size is 0.5~0.6 micron, Co powder Fisherman's The particle size is 0.6-1.0 microns.

[0094] (2) The raw materials are mixed in proportion, ball milled, mixed with paraffin molding agent and pressed into shape, and then put into a microwave vacuum sintering furnace for sintering.

[0095] (3) The microwave vacuum sintering furnace is produced intermittently, with a total power of 100 kilowatts. The microwave power is continuously adjustable. The microwave frequency is 2450 MHz. Vacuum protection or inert gas is used. Air-cooled rapid cooling cooling.

[0096](4) The sintering process is divided into four stages: inert gas positive pressure dewaxing, vacuum degassing solid-phase sintering, ...

Embodiment 3

[0103] A microwave vacuum sintering method for ultra-fine-grain cemented carbide, comprising the following steps:

[0104] (1) The cemented carbide is an ultrafine-grained cemented carbide, and the mass percent of its components is: WC powder 90%, Co powder 10%, wherein the WC Fischer grain size is 0.3~0.4 microns, and the Co powder Fischer powder The particle size is 0.6-1.0 microns.

[0105] (2) The raw materials are mixed in proportion, ball milled, mixed with paraffin molding agent and pressed into shape, and then put into a microwave vacuum sintering furnace for sintering.

[0106] (3) The microwave vacuum sintering furnace is produced intermittently, with a total power of 100 kilowatts. The microwave power is continuously adjustable. The microwave frequency is 2450 MHz. Vacuum protection or inert gas is used. Air-cooled rapid cooling cooling.

[0107] (4) The sintering process is divided into four stages: inert gas positive pressure dewaxing, vacuum degassing solid-pha...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com