Rodless oil production underground dosing production string as well as underground dosing system and dosing method thereof

A technology for producing pipe strings and dosing systems, which is applied in wellbore/well components, earthmoving, cleaning tools, etc., can solve the problem of poor effect of high liquid level oil wells, short validity period of chemical antiscalants for formation squeezing, and adverse effects. Dosing cycle and other issues, to reduce pump jam accidents, solve the poor anti-scaling effect, and save the total amount of dosing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

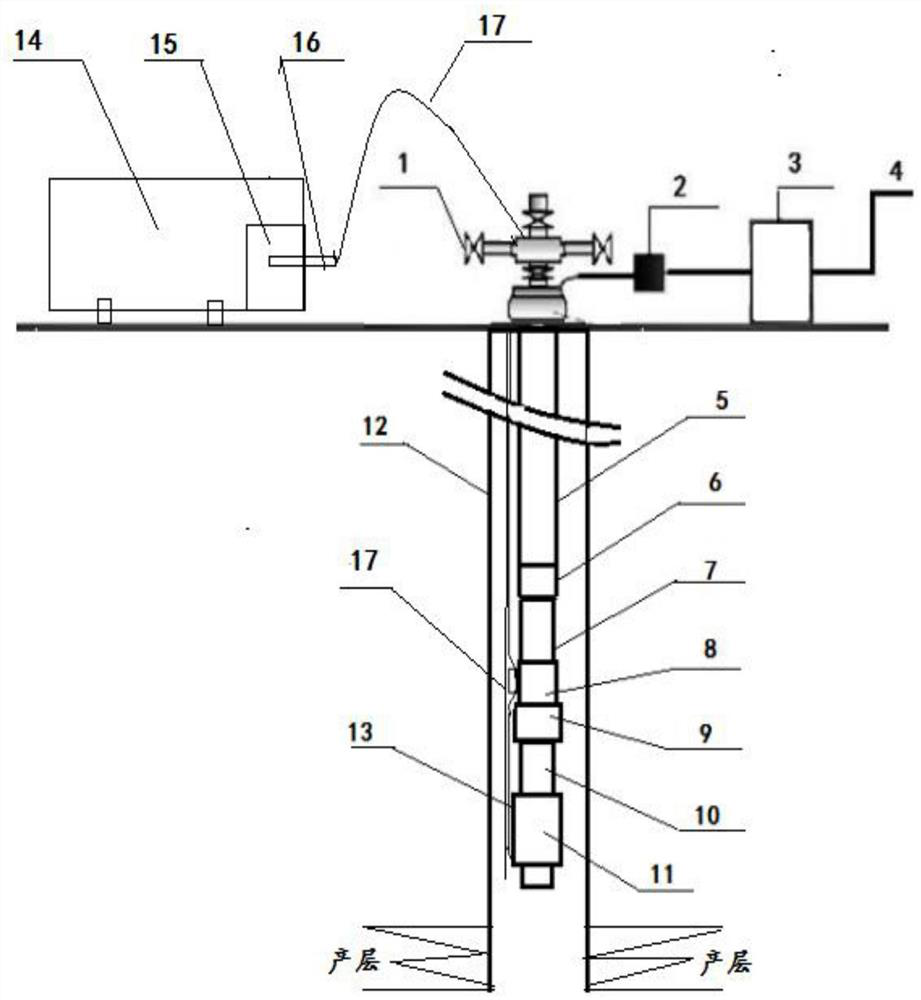

[0030] refer to figure 1 The shown a rodless oil production downhole dosing production string includes a drainer 6, a submersible pump 7, a coupling 9, a protector 10 and a submersible motor 11; the drainer 6, the submersible pump 7, The coupling 9, the protector 10 and the submersible motor 11 are sequentially connected from top to bottom.

[0031] When it is necessary to add chemicals to the well for anti-scaling, the submersible motor 11, protector 10, coupling 9, submersible pump 7, oil drainer 6 and oil pipe 5 are connected sequentially from bottom to top on the ground; The equipment is connected with a rodless oil production downhole dosing production string; then, the submersible motor 11, the protector 10, the coupling 9, the submersible pump 7, and the oil drainer 6 are put into the well in sequence, and the dosing related Bring the equipment into the well, go down to the preset position, install the wellhead and complete the well; store the anti-scaling agent that n...

Embodiment 2

[0036] refer to figure 1 A rodless oil production downhole dosing system shown includes at least one rodless downhole dosing production string, and also includes a medicine storage mechanism and a power and control mechanism; the power and control mechanism are respectively connected with the medicine storage mechanism and the medicine storage mechanism. The rodless oil production downhole dosing production string is connected to provide power for the drug storage mechanism and the rodless oil production downhole dosing production string, and to control the drug storage mechanism and the rodless oil production downhole dosing production string; the drug storage The mechanism is connected with the downhole chemical dosing production string in the rodless production well.

[0037] In actual use, connect the rodless oil production downhole dosing production string on the ground, and then connect the drug storage mechanism, power and control mechanism with the rodless downhole dos...

Embodiment 3

[0039] refer to figure 1 A rodless downhole dosing system for oil production shown is based on the second embodiment: the medicine storage mechanism includes a medicine storage tank 14, a medicine injection pump 15, a medicine control valve 16 and a stainless steel capillary injection pipe 17; A chemical injection pump 15 is connected to the chemical storage tank 14, the output end of the chemical injection pump 15 is connected to one end of the stainless steel capillary injection pipe 17 through the chemical control valve 16, and the other end of the stainless steel capillary injection pipe 17 is bound to the rodless oil production well. Dosing on the outside of the production string.

[0040] In actual use, first connect the rodless downhole oil production well dosing production string on the ground, and then fix one end of the stainless steel capillary injection pipe 17 between the submersible pump 7 and the submersible motor 11; , the protector 10, the coupling 9, the sub...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com