Interlayer ablation carbonization controllable experimental device for double-pulse solid rocket engine

A solid rocket, double-pulse technology, applied in rocket engine devices, machines/engines, jet propulsion devices, etc., can solve the problems of poor quality, insufficient strength, long working time, etc., and achieves low charge quality, convenient assembly, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

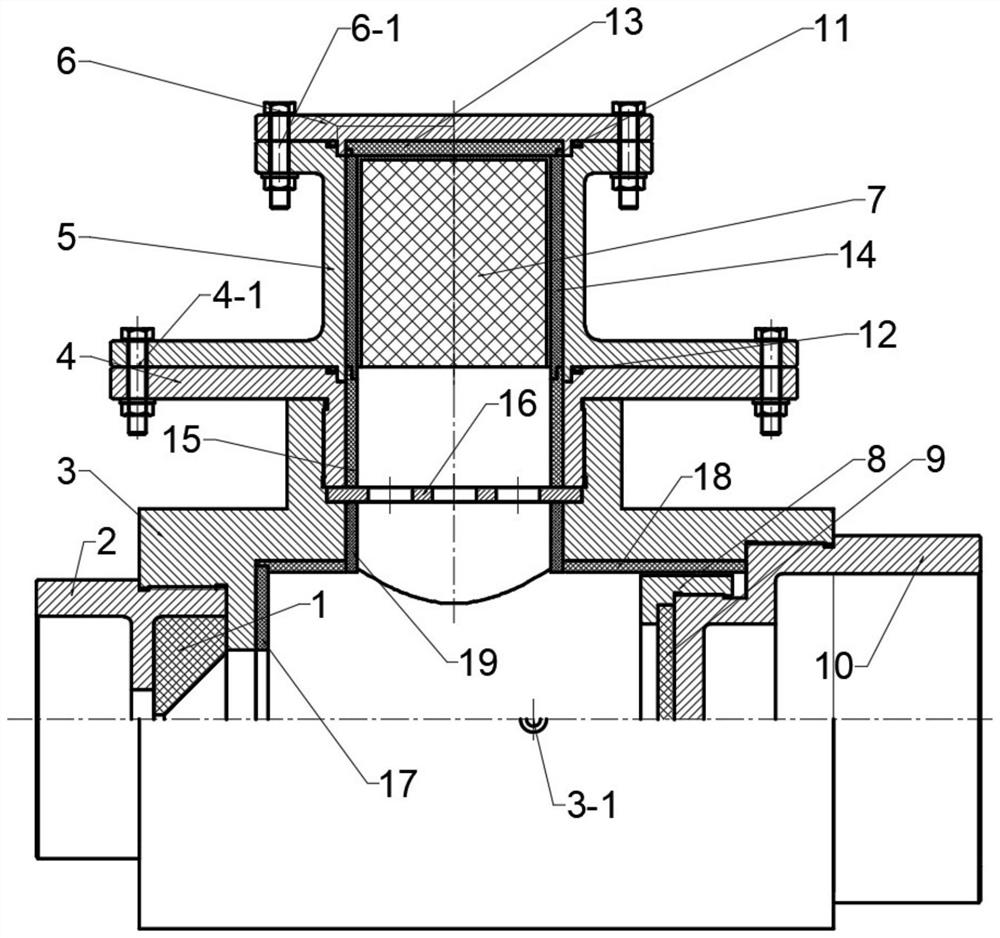

[0034] The present invention will be described in further detail below in conjunction with the accompanying drawings.

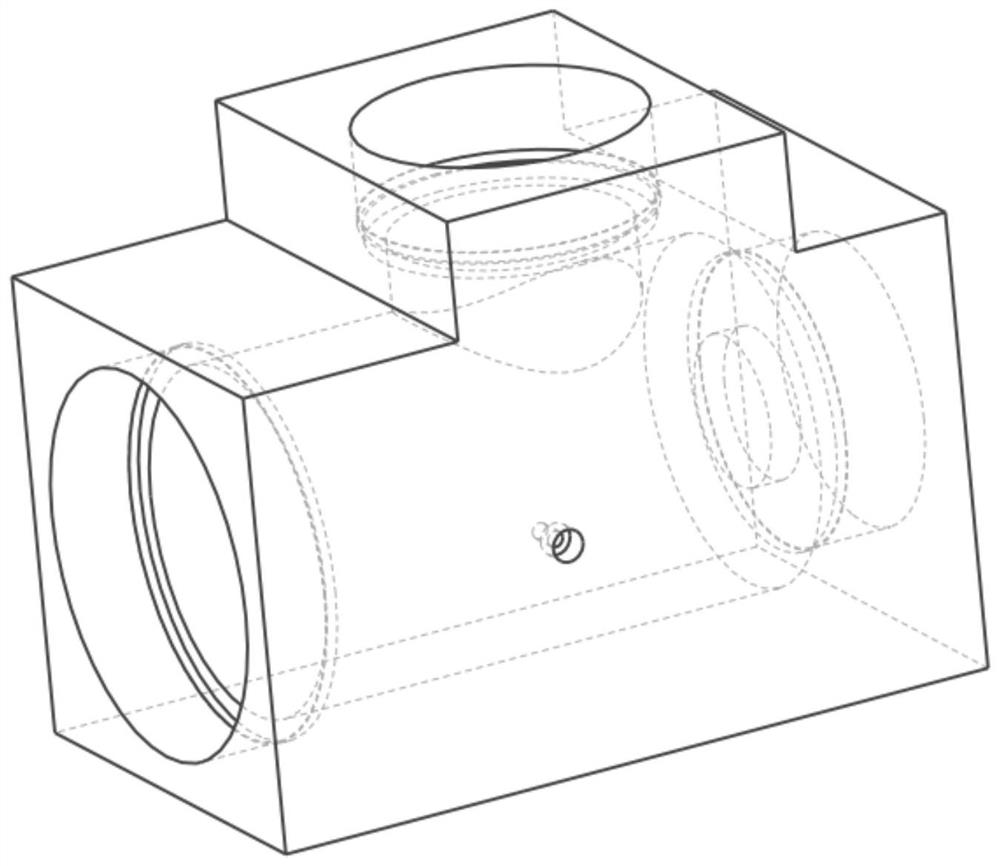

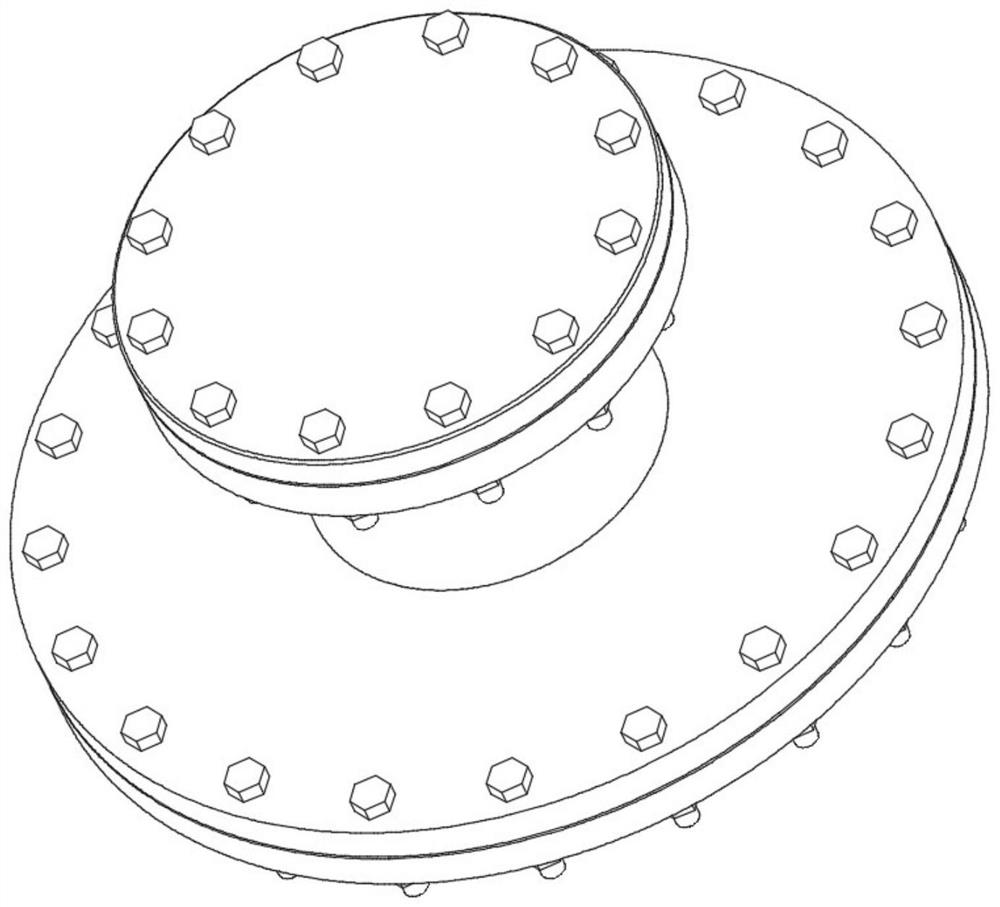

[0035] Such as figure 1As shown, a controllable experimental device for ablation and carbonization of a double-pulse solid rocket motor compartment, including an end-ignition charge assembly, a nozzle assembly, an interlayer ablation fixation assembly, and a combustion chamber cavity 3, an end-ignition charge assembly, The nozzle assembly, the interlayer ablation fixing assembly and the combustion chamber cavity 3 are connected by threads; the interlayer ablation fixing assembly includes the interlayer top cover 10, the interlayer ablation test piece 9 and the interlayer pressing screw 8, and the interlayer pressing The screw 8 is provided with a groove, the interlayer ablation test piece 9 is fixedly arranged in the inner groove of the interlayer pressing screw 8, and the interlayer top cover 10 is provided with two steps, and each step is provided with a sc...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com