Clamp assembly for testing edge-emitting laser diode and test equipment with same

A laser diode and edge-firing technology, which is used in diode testing, optical performance testing, optical instrument testing, etc., can solve the problem of inability to ensure complete electrical contact between the component to be tested and the spring probe, failure to expose the burn-in test function, and complex mechanisms, etc. question

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0019] Before the fixture assembly for testing the edge-emitting laser diode of the present invention and the testing equipment equipped with the assembly are described in detail in this embodiment, it should be noted that in the following description, similar components will use the same component symbols To represent. Moreover, the drawings of the present invention are only for illustration purposes, they are not necessarily drawn to scale, and not all details are necessarily presented in the drawings.

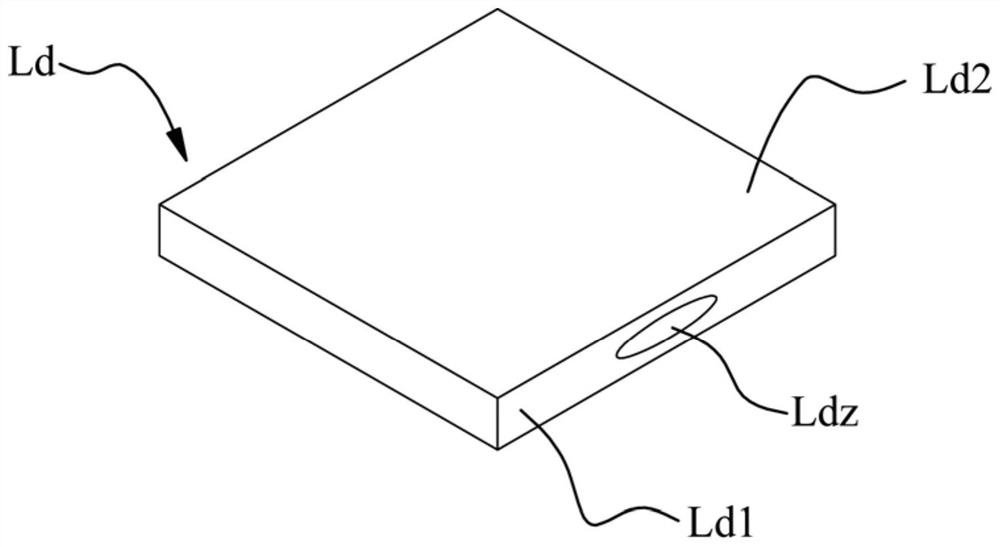

[0020] Please see first figure 1 , which is a schematic perspective view of an edge-firing laser diode Ld. Generally speaking, the edge-firing laser diode Ld includes a light-emitting surface Ld1 and a contact surface Ld2, wherein the light-emitting surface Ld1 includes a light-emitting region Ldz, that is, the laser light is emitted from the light-emitting region Ldz. In addition, a plurality of electrical contacts (not shown in the figure) are arranged on the contact sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com