Antibacterial auxiliary material having bacterial conditioning characteristic as well as preparation method and application of antibacterial auxiliary material

A technology of auxiliary materials and bacteria, applied in the field of pharmacy, to achieve the effect of protecting toxic and side effects, improving antibacterial efficacy, and promoting phagocytosis

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

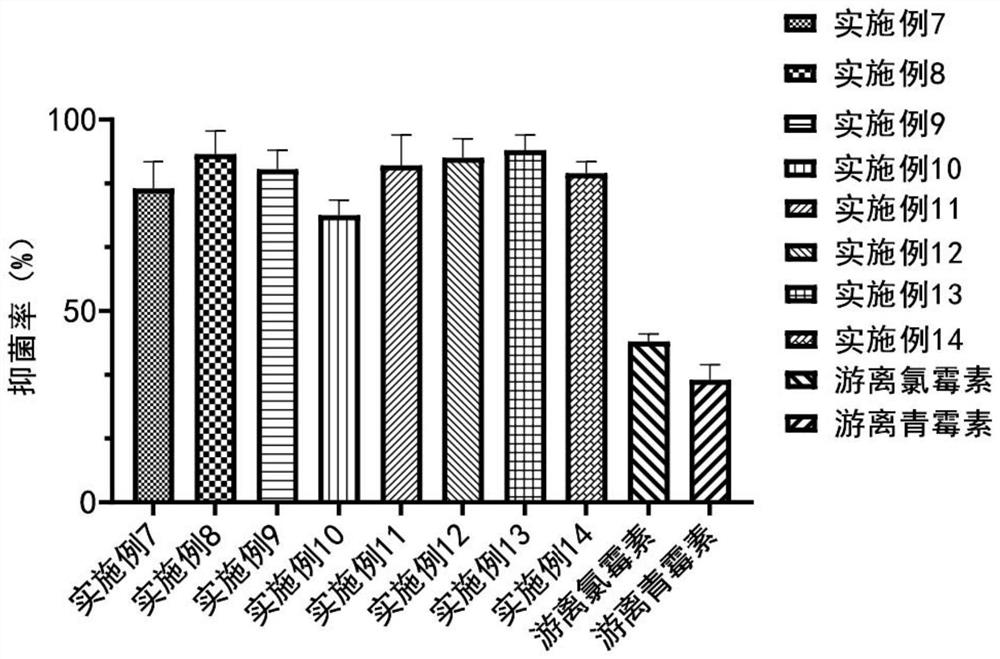

Examples

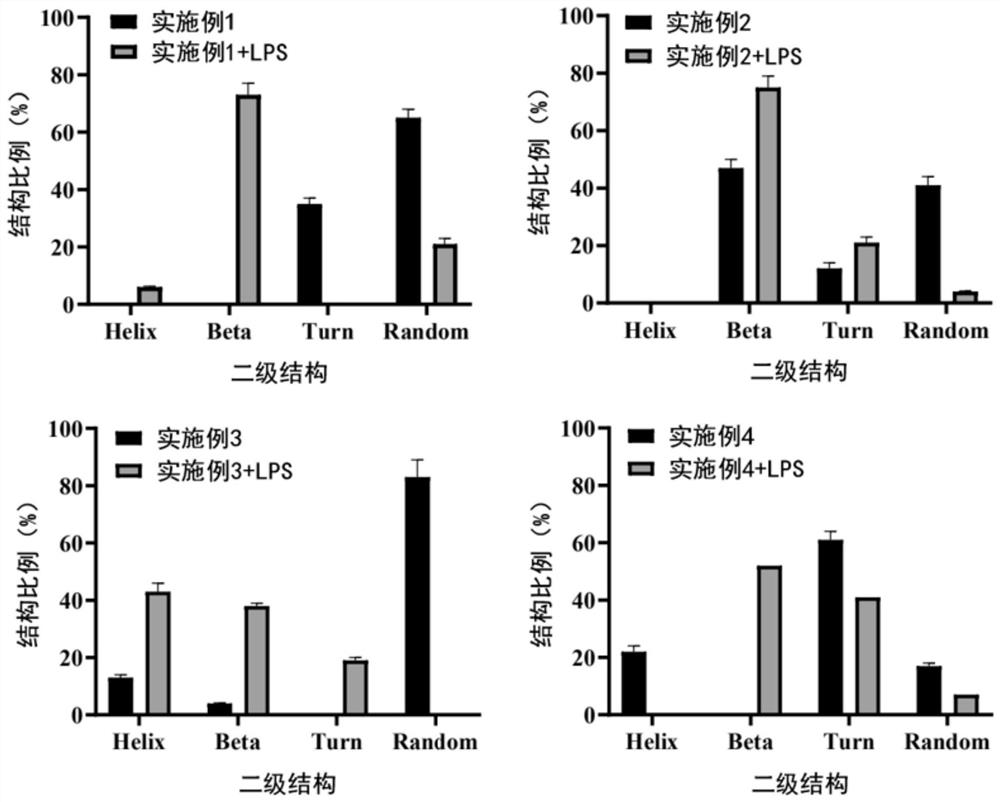

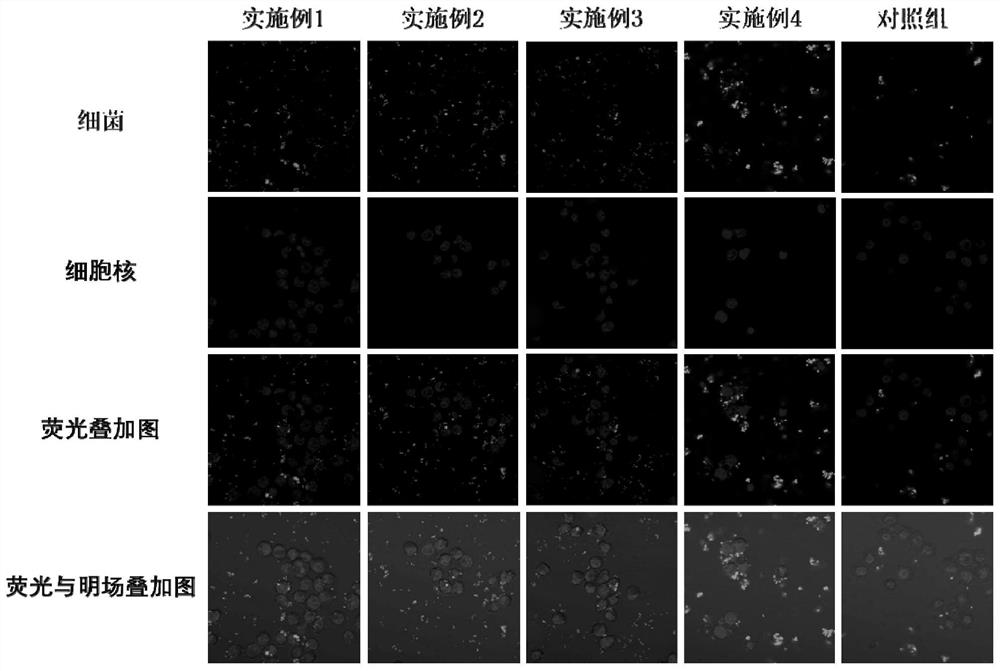

Embodiment 1

[0032] 2-Chlorobenzotrichlorotoluene resin (0.4 mmol, 100-200 mesh, 1% DVB) was placed in a synthesis column and immersed in DCM until the resin was completely dissolved. Fmoc-L-lys-OH was introduced into the reactor, and 0.5 mL of HBTU was used as the condensation agent. After reacting for 2 h under nitrogen stirring, the resin was washed 3 times with DMF and DCM. Then, 15 ml of the deprotection solution was added to the obtained Fmoc-protected amino acid resin. Subsequently, the Fmoc-amino acid-OH was reacted with the resin by the condensing agent HBTU according to the amino acid sequence from the C-terminus to the N-terminus in the expected lipopolysaccharide-binding protein mimetic peptide WKVRKSFFKLQGK. After each condensation reaction, the resin was washed alternately with DMF and methanol. A portion of the resin was then removed and examined by the ninhydrin method. The condensation is complete when the resin develops a pale yellow color. The resulting polypeptide w...

Embodiment 2

[0035] 2-Chlorobenzotrichlorotoluene resin (0.4 mmol, 100-200 mesh, 1% DVB) was placed in a synthesis column and immersed in DCM until the resin was completely dissolved. Fmoc-amino acid(biotin)-OH was introduced into the reactor, and 0.5 mL of HBTU was used as a condensing agent. After reacting for 2 h under nitrogen stirring, the resin was washed 3 times with DMF and DCM. Then, 15 ml of the deprotection solution was added to the obtained Fmoc-protected amino acid resin. Subsequently, Fmoc-amino acid-OH was reacted with the resin by the condensing agent HBTU according to the amino acid sequence from the C-terminus to the N-terminus in the expected mimetic peptide FHRNHRSPVTLL. After each condensation reaction, the resin was washed alternately with DMF and methanol. A portion of the resin was then removed and examined by the ninhydrin method. The condensation is complete when the resin develops a pale yellow color. The resulting polypeptide was cleaved from the resin and p...

Embodiment 3

[0037] 2-Chlorobenzotrichlorotoluene resin (0.4 mmol, 100-200 mesh, 1% DVB) was placed in a synthesis column and immersed in DCM until the resin was completely dissolved. Fmoc-L-lys-OH was introduced into the reactor, and 0.5 mL of HBTU was used as the condensation agent. After reacting for 2 h under nitrogen stirring, the resin was washed 3 times with DMF and DCM. Then, 15 ml of the deprotection solution was added to the obtained Fmoc-protected amino acid resin. Subsequently, Fmoc-amino acid-OH was reacted with the resin by the condensing agent HBTU according to the amino acid sequence from the C-terminus to the N-terminus in the expected mimetic peptide FHRNHRSPVTLL. After each condensation reaction, the resin was washed alternately with DMF and methanol. A portion of the resin was then removed and examined by the ninhydrin method. The condensation is complete when the resin develops a pale yellow color. The resulting polypeptide was cleaved from the resin and purified b...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com