Method for curing arsenic-containing sludge by using copper slag/cement composite cementing material

A technology of composite cementitious material and cement, which is applied in fixed/solidified sludge treatment, chemical instruments and methods, water/sludge/sewage treatment, etc. The effect of increasing compressive strength, reducing diffusion and damage, and enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

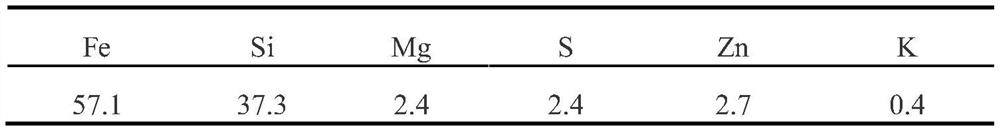

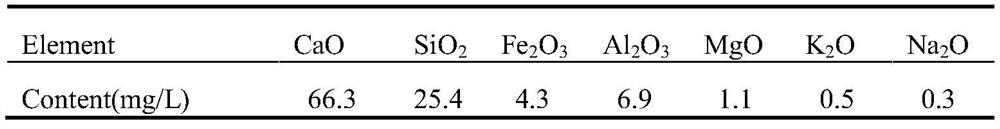

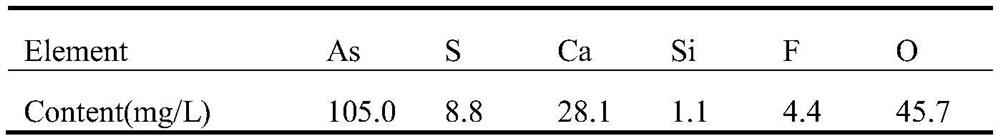

[0018] Example 1: The copper slag in this example is taken from a smelter in Yunnan, and the main components are shown in Table 1; the cement is from a factory, and the main components are shown in Table 2; the arsenic-containing sludge comes from the sulfuric acid workshop of a zinc smelter in Southwest China The sludge obtained after removing arsenic in wastewater by lime neutralization and precipitation method has main components as shown in Table 3;

[0019] Table 1 Composition of copper slag

[0020]

[0021] Table 2 Cement composition

[0022]

[0023] Table 3 Sludge Composition

[0024]

[0025] A method for solidifying arsenic-containing sludge with copper slag / cement composite cementitious material, the specific steps are as follows:

[0026] (1) after copper slag and cement are ground respectively, cross 200 mesh sieves to obtain copper slag powder and cement powder;

[0027] (2) Step (1) copper slag powder and cement powder are mixed uniformly to obtain ...

Embodiment 2

[0036] Example 2: The copper slag in this example is taken from a smelter in Yunnan, the main components are shown in Table 5; the cement is from a factory, and the main components are shown in Table 6; the arsenic-containing sludge is from the sulfuric acid workshop of a zinc smelter in Southwest China The sludge obtained after removing arsenic in wastewater by lime neutralization and precipitation method has main components as shown in Table 7;

[0037] Table 5 Copper slag composition

[0038]

[0039] Table 6 Portland cement composition

[0040]

[0041] Table 7 Sludge Composition

[0042]

[0043] A copper slag / cement composite cementitious material solidifies arsenic-containing sludge, and the specific steps are as follows:

[0044] (1) Portland cement and blast furnace slag are ground and passed through a 300-mesh sieve to obtain Portland cement powder and blast furnace slag powder;

[0045] (2) Mix the Portland cement powder and blast furnace slag powder in ...

Embodiment 3

[0054]Example 3: The copper slag in this example is taken from a smelter in Yunnan, and the main components are shown in Table 9; the cement is from a factory, and the main components are shown in Table 10; the arsenic-containing sludge comes from the sulfuric acid workshop of a zinc smelter in Southwest China The sludge obtained after removing arsenic in wastewater by lime neutralization and precipitation method has main components as shown in Table 11;

[0055] Table 9 copper slag composition

[0056]

[0057] Table 10 Cement composition

[0058]

[0059] Table 11 Sludge Composition

[0060]

[0061] A method for solidifying arsenic-containing sludge with copper slag / cement composite cementitious material, the specific steps are as follows:

[0062] (1) Portland cement and blast furnace slag are ground and passed through a 300-mesh sieve to obtain Portland cement powder and blast furnace slag powder;

[0063] (2) Mix the Portland cement powder and blast furnace s...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

| Compressive strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap