High-refractive-index photosensitive resin and preparation method thereof

A technology of photosensitive resin and high refractive index, applied in the field of photosensitive resin, can solve the problem of low refractive index and achieve the effect of high hardness, low price and good chemical resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

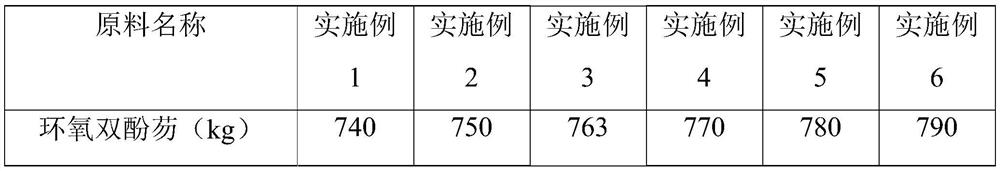

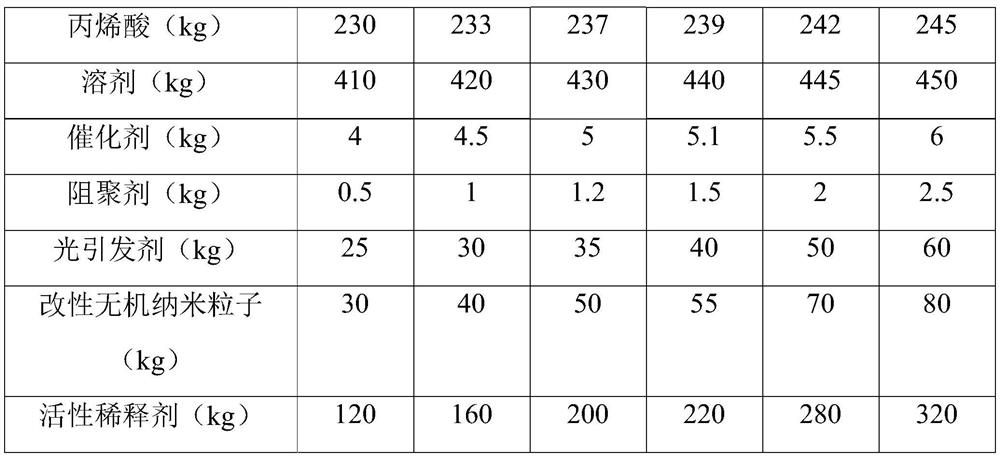

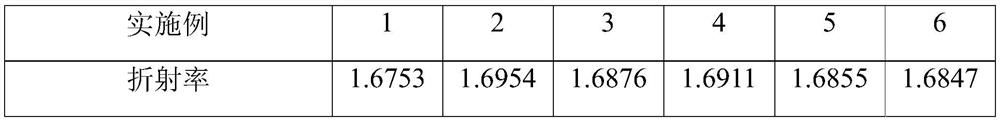

Examples

Embodiment 1

[0041] This embodiment provides a method for preparing the above-mentioned high refractive index photosensitive resin, which includes the following steps:

[0042] 1) The reactive diluent is subjected to 4.2 hours of reduced pressure and vacuum treatment at a temperature of 78°C.

[0043] 2) After 3-glycidylpropyltrimethoxysilane and titanium dioxide nanoparticles are mixed at a molar ratio of 1:2.5, they are ultrasonically dispersed for 3 hours to obtain modified inorganic nanoparticles.

[0044] 3) Add the proportioned epoxy bisphenol fluorene and solvent into the reaction kettle, turn on the stirring, heat up to 102° C., and stir until the epoxy bisphenol fluorene is completely dissolved.

[0045] 4) Mix the proportioned amount of acrylic acid, catalyst and polymerization inhibitor to obtain a mixture. The mixture is added into the reaction kettle three times within 25 minutes, reacted for 7 hours, and then discharged. Add proportioned amount of modified inorganic nanoparticles and ...

Embodiment 2

[0047] This embodiment provides a method for preparing the above-mentioned high refractive index photosensitive resin, which includes the following steps:

[0048] 1) The active diluent is subjected to vacuum treatment under reduced pressure for 4 hours at a temperature of 80°C.

[0049] 2) After mixing 3-(methacryloxy)propyltrimethoxysilane and silica nanoparticles at a molar ratio of 1:3, ultrasonically dispersing for 2 hours to obtain modified inorganic nanoparticles.

[0050] 3) Add the proportioned epoxy bisphenol fluorene and solvent into the reaction kettle, turn on the stirring, heat up to 105° C., and stir until the epoxy bisphenol fluorene is completely dissolved.

[0051] 4) Mix the proportion of acrylic acid, catalyst and polymerization inhibitor to obtain a mixture. The mixture is added into the reaction kettle 4 times within 30 minutes, reacted for 6.5 hours, discharged, and added the proportion of modified inorganic nanoparticles and activity The diluent and the photoin...

Embodiment 3

[0053] This embodiment provides a method for preparing the above-mentioned high refractive index photosensitive resin, which includes the following steps:

[0054] 1) The active diluent is subjected to vacuum treatment under reduced pressure for 3.8 hours at a temperature of 82°C.

[0055] 2) After mixing 3-(acryloxypropyl)trimethoxysilane and zirconia nanoparticles at a molar ratio of 1:5, ultrasonically dispersing for 1 hour to obtain modified inorganic nanoparticles.

[0056] 3) Add the proportioned epoxy bisphenol fluorene and solvent into the reaction kettle, turn on the stirring, heat up to 108° C., and stir until the epoxy bisphenol fluorene is completely dissolved.

[0057] 4) Mix the proportioned amount of acrylic acid, catalyst and polymerization inhibitor to obtain a mixture. The mixture is added to the reactor in 5 times within 35 minutes, reacted for 6 hours, discharged, and added the proportioned amount of modified inorganic nanoparticles and activity The diluent and the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| refractive index | aaaaa | aaaaa |

| refractive index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com