Rigid-flexible out-of-phase and microstructure coupling material, and preparation method and application thereof

A technology of microstructure and flexible materials, applied in the field of materials, can solve the problems of reducing the vibration energy transfer level of shafting, the frequency bandwidth of vibration source, complexity, etc., and achieve good vibration and noise reduction effect, taking into account the effect of strength and damping.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This example provides a rigid-flexible out-of-phase and microstructure coupling material, which is actually prepared by the following method:

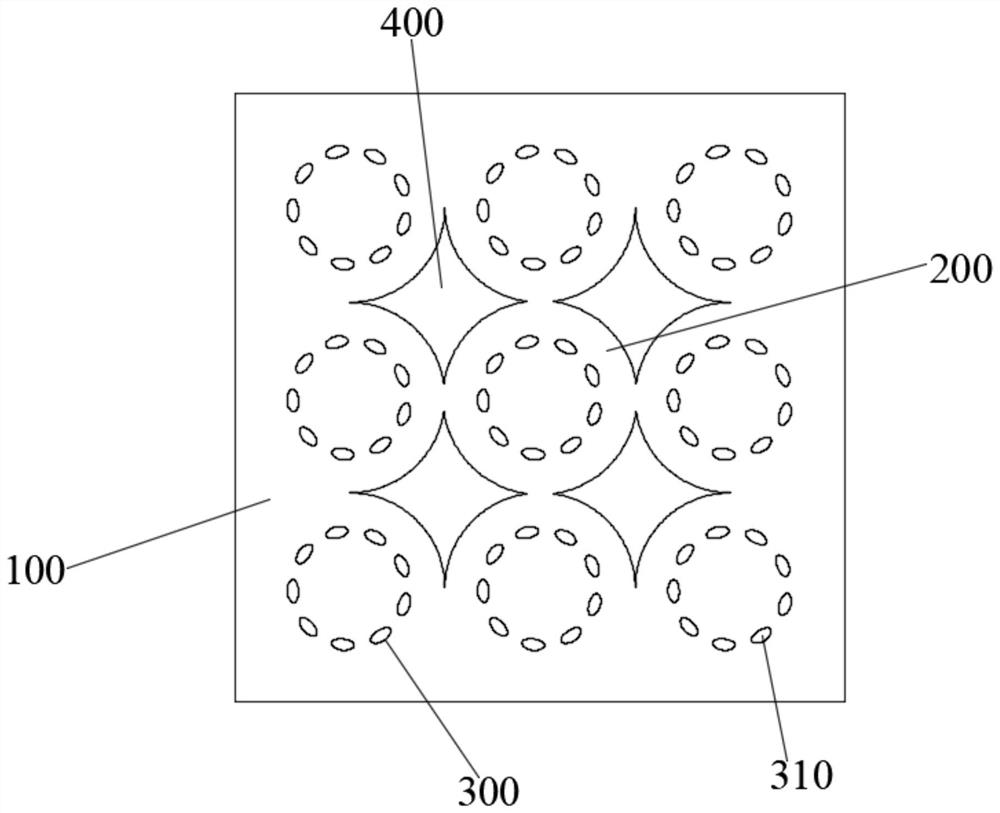

[0034] S1, use SolidWorks software to model. Such as figure 1 and figure 2 As shown, the substrate 100 model containing 9 volume units 200 is used as a printing sample to establish a printing model, and the model structure of creating a cylindrical volume unit 200 is as follows image 3 As shown, the volume unit 200 has a diameter of 5mm and a height of 10mm, and the model structure of the spiral structure 300 is as follows Figure 4 As shown, the helical structure 300 is composed of 9 helicoids 310 arranged circumferentially along the axis of the cylindrical unit 200, the radius of the helical circle of the helical structure 300 composed of 9 helicoids 310 is 3 mm, and the pitch is 20 mm; 9 volume units 200 A 3-volume unit arrangement is generated so that four adjacent volume units 200 are surrounded to form pores 400 . In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com