Preparation method and application of silver-titanium dioxide-carbon nano composite material

A nanocomposite material, titanium dioxide technology, applied in chemical instruments and methods, special compound water treatment, metal/metal oxide/metal hydroxide catalysts, etc., can solve problems such as limited promotion and application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] Embodiment 1 A kind of preparation method of silver-titanium dioxide-carbon nanocomposite material:

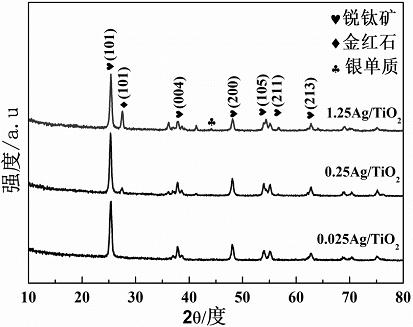

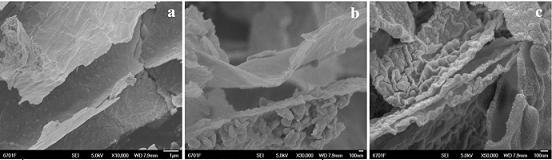

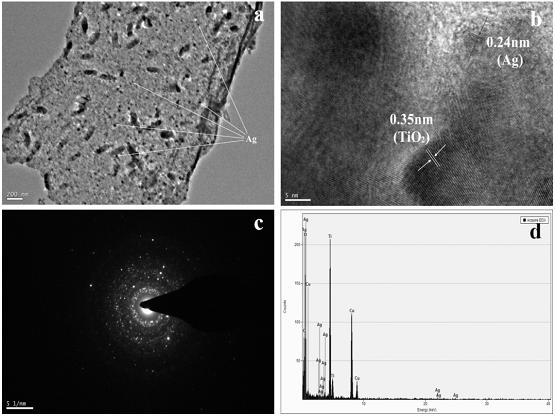

[0034] Add 0.75g of biomass corn stalks to 50 mL of mixed ethanol solution of silver nitrate and butyl titanate, and soak them in the dark for 24 hours, so that butyl titanate and silver nitrate can be fully adsorbed on the biomass corn stalks. Under the sunlight for 2 hours, the Ag ions undergo photochemical reduction reaction to form Ag simple substance; finally, the TiO 2 The biomass corn stalks with nanoparticles and simple Ag were taken out, dried naturally and placed in a crucible, and calcined in an air atmosphere in a muffle furnace at a heating rate of 5 °C / min to 700 °C for 2 hours. After cooling to room temperature, 0.025Ag / TiO 2 @C nanocomposites.

[0035] Wherein: the preparation method of the mixed ethanol solution of silver nitrate and butyl titanate refers to first preparing the butyl titanate ethanol solution whose concentration is 0.0585mol / L; The m...

Embodiment 2

[0037] Example 2 A preparation method of silver-titanium dioxide-carbon nanocomposite material:

[0038] Add 0.75g of biomass corn stalks to 50 mL of mixed ethanol solution of silver nitrate and butyl titanate, and soak them in the dark for 24 hours, so that butyl titanate and silver nitrate can be fully adsorbed on the biomass corn stalks. Under the sunlight for 2 hours, the Ag ions undergo photochemical reduction reaction to form Ag simple substance; finally, the TiO 2 Biomass corn stalks with nanoparticles and simple Ag were taken out, dried naturally, placed in a crucible, and calcined in an air atmosphere in a muffle furnace at a heating rate of 5°C / min to 700°C. Cool to room temperature to get 0.05Ag / TiO 2 @C nanocomposites.

[0039] Wherein: the preparation method of the mixed ethanol solution of silver nitrate and butyl titanate refers to first preparing the butyl titanate ethanol solution whose concentration is 0.0585mol / L; The molar ratio of butyl titanate / butyl t...

Embodiment 3

[0041] Example 3 A preparation method of silver-titanium dioxide-carbon nanocomposite material:

[0042] Add 0.75g of biomass corn stalks to 50 mL of mixed ethanol solution of silver nitrate and butyl titanate, and soak them in the dark for 24 hours, so that butyl titanate and silver nitrate can be fully adsorbed on the biomass corn stalks. Under the sunlight for 2 hours, the Ag ions undergo photochemical reduction reaction to form Ag simple substance; finally, the TiO 2 Biomass corn stalks with nanoparticles and simple Ag were taken out, dried naturally, placed in a crucible, and calcined in an air atmosphere in a muffle furnace at a heating rate of 5°C / min to 700°C. Cool to room temperature to get 0.1Ag / TiO 2 @C nanocomposites.

[0043] Wherein: the preparation method of the mixed ethanol solution of silver nitrate and butyl titanate refers to first preparing the butyl titanate ethanol solution whose concentration is 0.0585mol / L; The molar ratio of butyl titanate to butyl...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com