High-pressure preparation method of sodium pentazole

A technology of sodium pentazole and high pressure is applied in the field of high temperature and high pressure preparation of sodium pentazole to achieve the effects of saving synthesis cost and simple method

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The invention provides a high-pressure preparation method of sodium pentazole, comprising the following steps:

[0022] Sodium azide is filled in the diamond anvil sample cavity, and then the sodium azide in the sample cavity is pressurized to obtain sodium pentazole; the pressurized pressure is above 21.6 GPa.

[0023] In the present invention, the method for forming the sample cavity is preferably: use a diamond counter-anvil press to pre-press the steel sheet, and drill a hole in the center of the indentation, using the hole as the sample cavity; the diamond counter-anvil press The diameter of the anvil surface is preferably 300 μm, and the diameter of the sample cavity is preferably 50-100 μm.

[0024] After the sample cavity is formed, the present invention fills the sodium azide in the sample cavity. In the present invention, the sodium azide is preferably sodium azide powder; when filling sodium azide, make sodium azide completely fill the sample cavity, without...

Embodiment 1

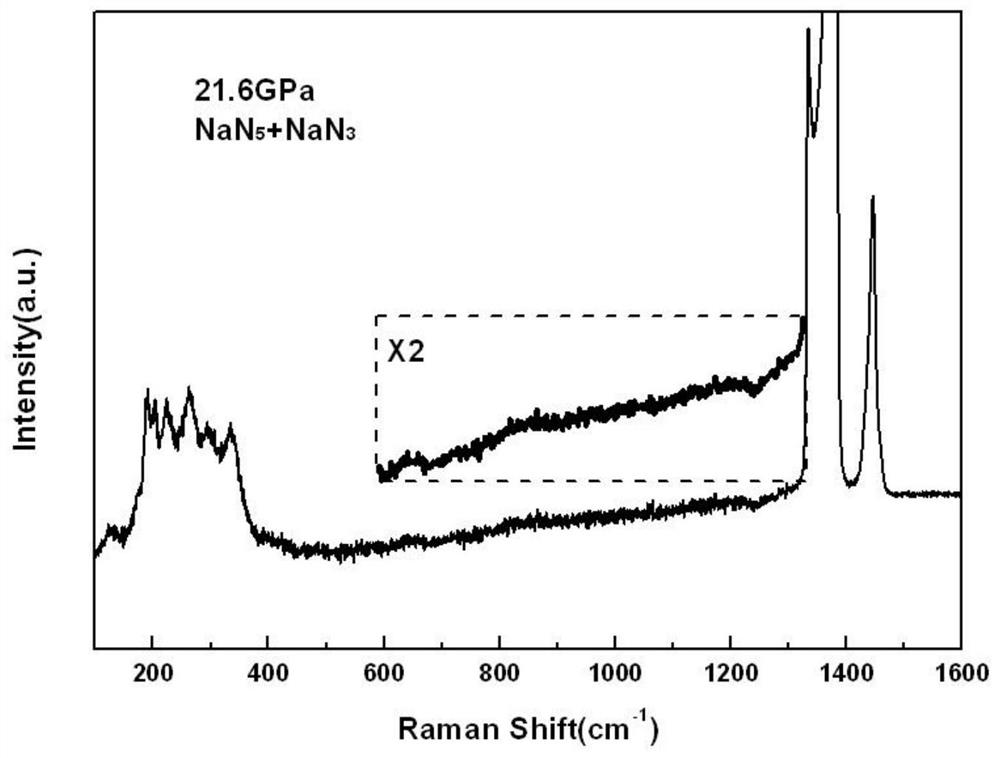

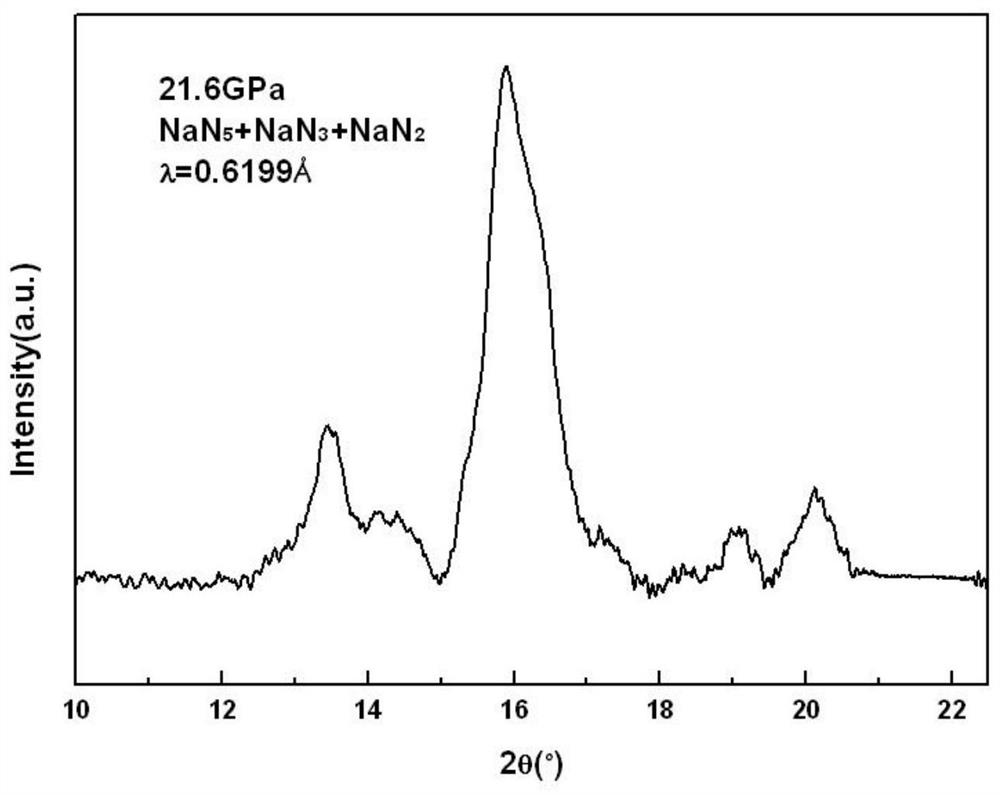

[0029] A diamond counter-anvil press with an anvil surface of 300 μm was used to pre-press the steel sheet, and a circular hole with a diameter of 100 μm was drilled in the center of the indentation, which was used as a sample cavity for loading raw materials. First add a ruby ball doped with a small amount of chromium as a pressure mark, then fill the excess sodium azide powder into the sample cavity, completely fill the sample cavity, and pressurize without adding any other medium as the pressure transmission medium. When the pressure increased to 21.6GPa, part of the sodium azide dissociated and recombined to obtain sodium pentazole (NaN 5 ) and sodium diazide (NaN 2 ). The Raman scattering spectrum and X-ray diffraction spectrum of gained product see figure 1 and figure 2 .

[0030] according to figure 1 It can be seen that the Raman scattering spectrum of the product at 21.6GPa is located at 180-600cm -1 Range and 1446cm -1 represents NaN 3 Outside the Raman vi...

Embodiment 2

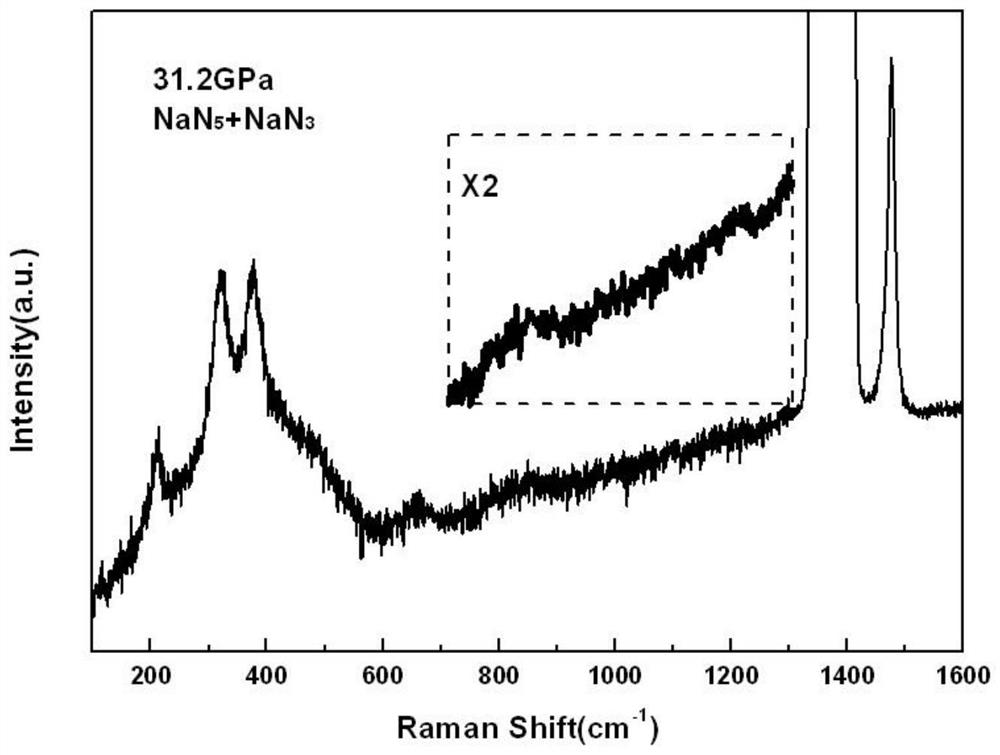

[0033] The filling method of the press, the sample cavity and the sodium azide powder is the same as in Example 1. When the pressure increased to 31.2GPa, part of the sodium azide dissociated and recombined to obtain sodium pentazole (NaN 5 ) and sodium diazide (NaN 2 ). The Raman scattering spectrum and X-ray diffraction spectrum of the product are shown in image 3 and Figure 4 .

[0034] according to image 3 It can be seen that: at 31.2GPa, the Raman scattering spectrum of the product is located at 180-600cm -1 range represents NaN 3 The Raman vibrational peaks broaden, from five vibrational peaks to three peaks and a large broad package, at 845 and 1180cm -1 The slightly enhanced intensity of the wide packet at the position indicates that the NaN 5 The amount has increased, a small amount of NaN 5 Appear.

[0035] according to Figure 4 It can be seen that in the XRD diffraction pattern of the product at 31.2GPa, the positions at 16.6° and 17.5° belong to NaN ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com