Surface-modified mineral casting and preparation process thereof

A technology for mineral castings and surface modification, applied in the field of mineral castings manufacturing, can solve problems such as easy cracking and shedding, and achieve the effect of providing usable performance and broadening the application field.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

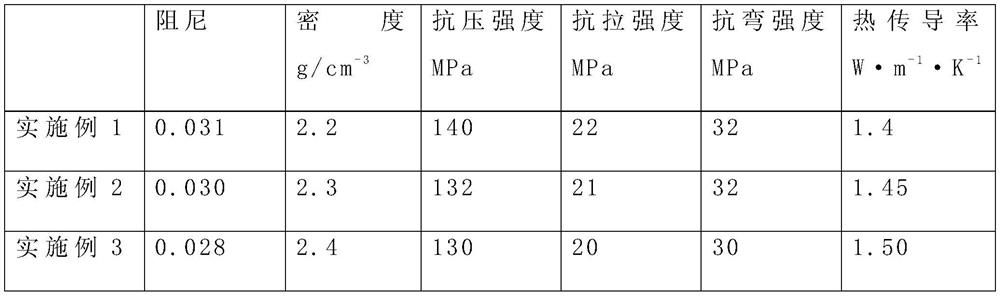

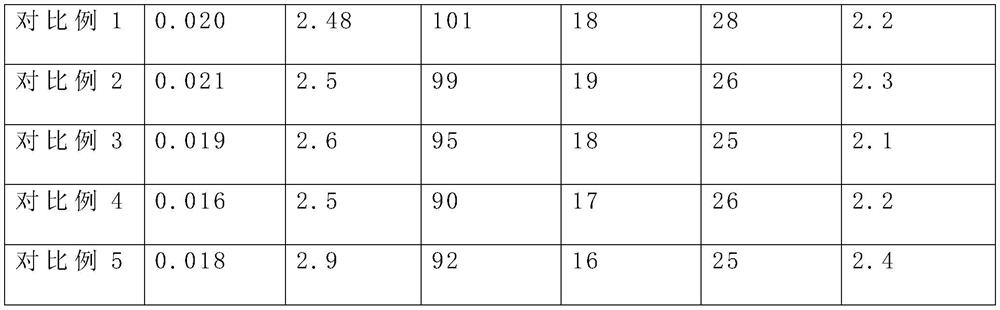

Examples

Embodiment 1

[0045] Example 1 A mineral casting with surface modification

[0046] The raw material of the mineral casting includes the following components calculated in parts by weight:

[0047] 60 parts of coarse aggregate, the particle size of coarse aggregate is 6mm, the material is granite,

[0048] 28 parts of fine aggregate, the particle size of fine aggregate is 3.6mm, the material is basalt,

[0049] 2 parts of reinforcing fiber, the length of glass fiber is 3mm,

[0050] 14 parts of epoxy resin,

[0051] 2 parts of epoxy resin masterbatch,

[0052] 2 parts dextrin,

[0053] 4 parts sodium carboxymethyl cellulose,

[0054] 5 parts of zirconium powder,

[0055] 4 parts fly ash,

[0056] 2 parts vermiculite,

[0057] 0.8 part of amine curing agent,

[0058] 0.4 parts of polyimide.

[0059] Preparation technique: (1) weigh above-mentioned components by weight, for subsequent use;

[0060] (2) Mix the epoxy resin masterbatch, dextrin, sodium carboxymethyl cellulose, and zi...

Embodiment 2

[0064] 55 parts of coarse aggregate, the particle size of coarse aggregate is 5mm, the material is granite,

[0065] 22 parts of fine aggregate, the particle size of fine aggregate is 4mm, the material is basalt,

[0066] 2 parts of reinforcing fiber, the length of glass fiber is 2mm,

[0067] 16 parts of epoxy resin,

[0068] 2 parts of epoxy resin masterbatch,

[0069] 2 parts dextrin,

[0070] 5 parts of sodium carboxymethyl cellulose,

[0071] 6 parts of zirconium powder,

[0072] 6 parts of fly ash,

[0073] 3 parts vermiculite,

[0074] 1.0 parts of amine curing agent,

[0075] 0.3 part of polyimide.

[0076] The preparation process is the same as that in Example 1.

Embodiment 3

[0078] 50 parts of coarse aggregate, the particle size of coarse aggregate is 8mm, the material is granite,

[0079] 20 parts of fine aggregate, the particle size of fine aggregate is 3mm, the material is basalt,

[0080] 3 parts of reinforcing fiber, the length of glass fiber is 4mm,

[0081] 20 parts of epoxy resin,

[0082] 3 parts of epoxy resin masterbatch,

[0083] 1 part dextrin,

[0084] 2 parts sodium carboxymethyl cellulose,

[0085] 8 parts of zirconium powder,

[0086] 3 parts fly ash,

[0087] 4 parts vermiculite,

[0088] 1.5 parts of amine curing agent,

[0089] 0.2 part of polyimide.

[0090] The preparation process is the same as that in Example 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com