Dealkalization and purification method used in production of precipitated calcium carbonate

A technology of precipitated calcium carbonate and production process, which is applied in the direction of calcium carbonate/strontium/barium, etc., and can solve problems such as the inability to stabilize the pH value of light calcium carbonate products and the inability to improve the brightness of calcium carbonate products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

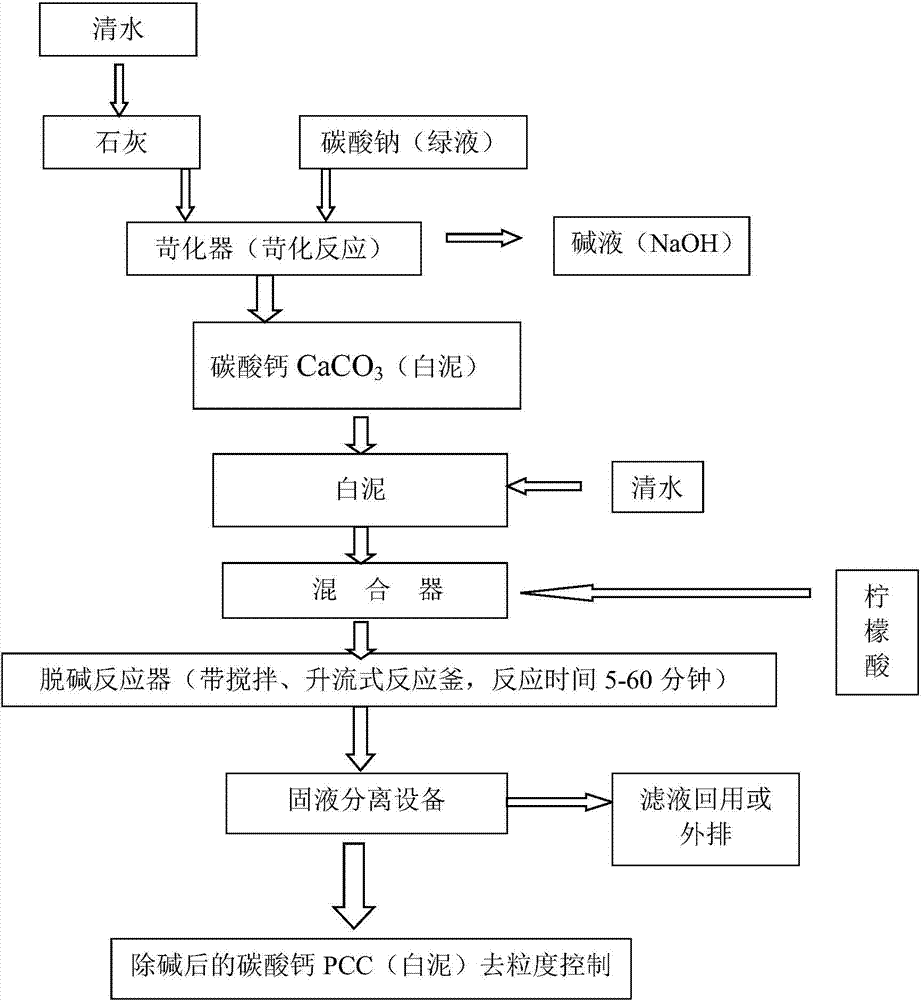

Image

Examples

Embodiment 1

[0043] (1) 10kg of causticizing white mud calcium carbonate system is concentrated to 20wt% (solid content), and its residual alkali content is measured to be 1.0wt%, and the white mud brightness is 86%, and the pH value exceeds 14;

[0044] (2) Then add citric acid solution with a mass concentration of 5%, react and stir for 20 minutes to make a mixed solution; the amount of citric acid solution is 3.56L;

[0045] (3) Send the mixed solution in step (2) into a fully sealed upflow reactor, control the reaction temperature at 25°C, react and stir for 20 minutes;

[0046] (4) After the reaction is completed, the mixed solution is sent to the solid-liquid separation device for dilution and washing with water, and then goes down to the process for particle size control.

[0047] Measurement results after the reaction: the pH value of the calcium carbonate product is 8.02, the purity is 94.61%, the brightness is 88.39%; the residual alkali content is 0.02wt%.

Embodiment 2

[0049] (1) 10kg of causticizing white mud calcium carbonate system is adjusted to 25wt% (solid content), and its residual alkali content is measured to be 0.8wt%, and the white mud brightness is 86%, and the pH value exceeds 14;

[0050] (2) Then add citric acid solution with a mass concentration of 5%, react and stir for 10 minutes to make a mixed solution; the amount of citric acid solution is 2.79L;

[0051] (3) Send the mixed solution in step (2) into a fully sealed upflow reactor, control the reaction temperature at 30°C, react and stir for 30 minutes;

[0052] (4) After the reaction is completed, the mixed solution is sent to the solid-liquid separation device for dilution and washing with water, and then goes down to the process for particle size control.

[0053] Measurement results after reaction: the pH value of the calcium carbonate product is 8.11, the purity is 94.32%, the brightness is 88.56%; the residual alkali content is 0.01wt%.

Embodiment 3

[0055] (1) 10kg of causticizing white mud calcium carbonate system is concentrated to 35wt% (solid content), and its residual alkali content is measured to be 0.7wt%, and the white mud brightness is 85%, and the pH value exceeds 14;

[0056] (2) Then add citric acid solution with a mass concentration of 5%, react and stir for 25 minutes to make a mixed solution; the amount of citric acid solution is 2.39L;

[0057] (3) Send the mixed solution in step (2) into a fully sealed upflow reactor, control the reaction temperature at 35°C, react and stir for 50 minutes;

[0058] (4) After the reaction is completed, the mixed solution is sent to the solid-liquid separation device for dilution and washing with water, and then goes down to the process for particle size control.

[0059] Measurement results after the reaction: the pH value of the calcium carbonate product is 7.83, the purity is 95.13%, the brightness is 88.25%; the residual alkali content is 0.01wt%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com