Fertilizer for vegetable planting and production process thereof

A production process and fertilizer technology, applied in the field of vegetable planting fertilizer and its production process, can solve problems such as inconvenient crushing of fertilizer, and achieve the effects of reducing lodging, reducing nitrogen loss, and improving soil physical and chemical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] A vegetable planting fertilizer prepared from the following raw materials in parts by weight:

[0037] 15 parts of pond ditch mud, 1 part of oil shale ash, 1.5 parts of ferrous sulfate, 2 parts of monoammonium phosphate, 1 part of manganese sulfate, 0.5 parts of potassium chloride, 1.5 parts of zinc sulfate, 1.2 parts of potassium magnesium sulfate fertilizer, 0.25 parts of molybdenum ammonium acid, 1 part attapulgite powder, 15 parts animal hair, 1 part sweet potato powder, 15 parts urea.

Embodiment 2

[0039] A vegetable planting fertilizer prepared from the following raw materials in parts by weight:

[0040] 20 parts of pond ditch mud, 2 parts of oil shale ash, 3 parts of ferrous sulfate, 4 parts of monoammonium phosphate, 2 parts of manganese sulfate, 1.3 parts of potassium chloride, 2.5 parts of zinc sulfate, 1.7 parts of potassium magnesium sulfate fertilizer, 0.5 parts of molybdenum ammonium acid, 3 parts of attapulgite powder, 20 parts of animal hair, 5 parts of sweet potato powder, and 30 parts of urea.

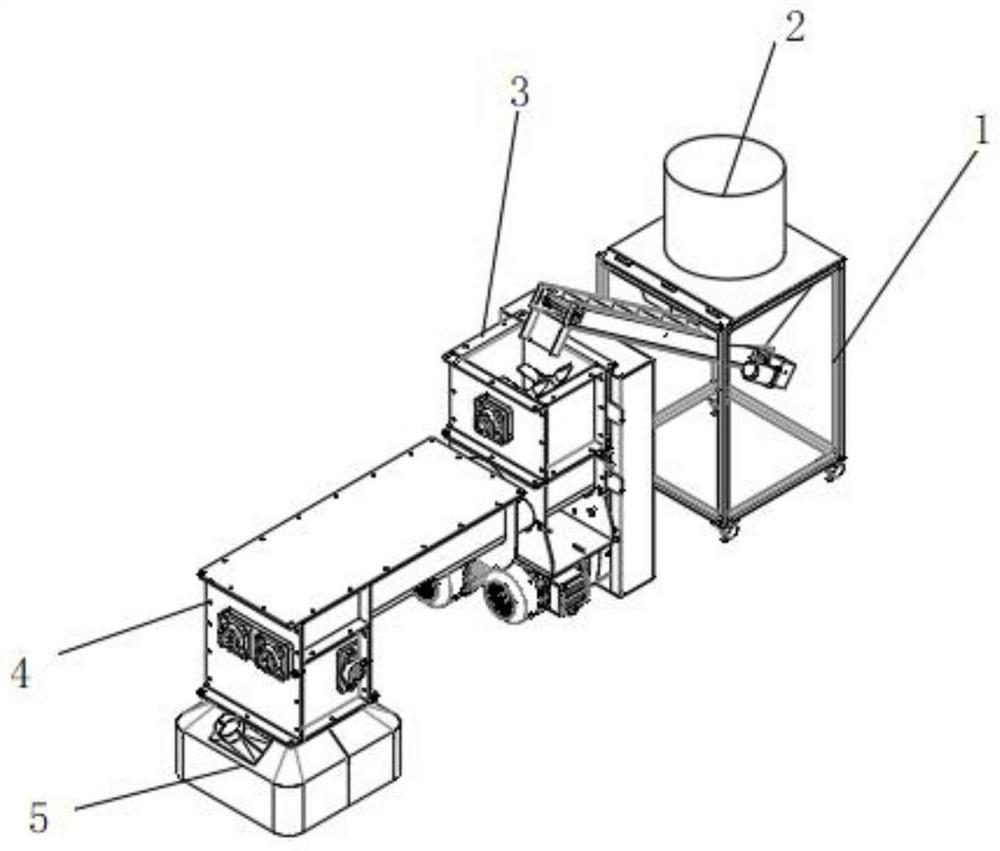

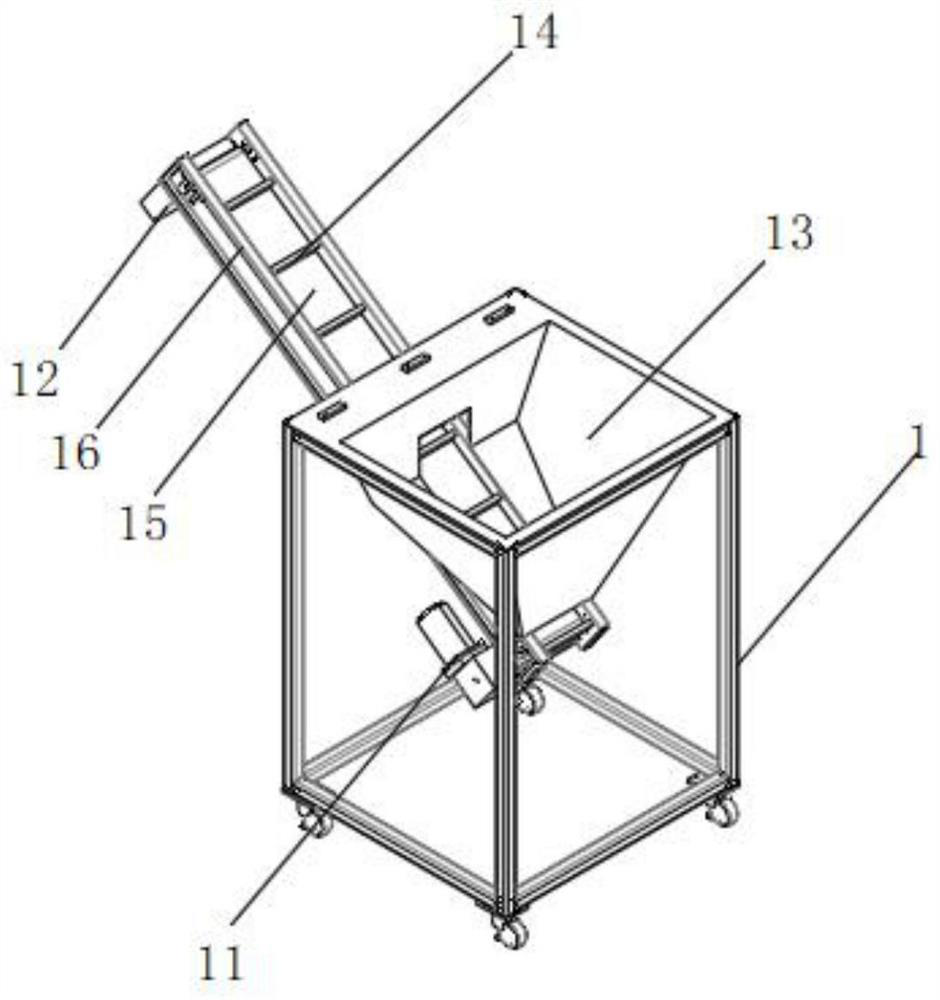

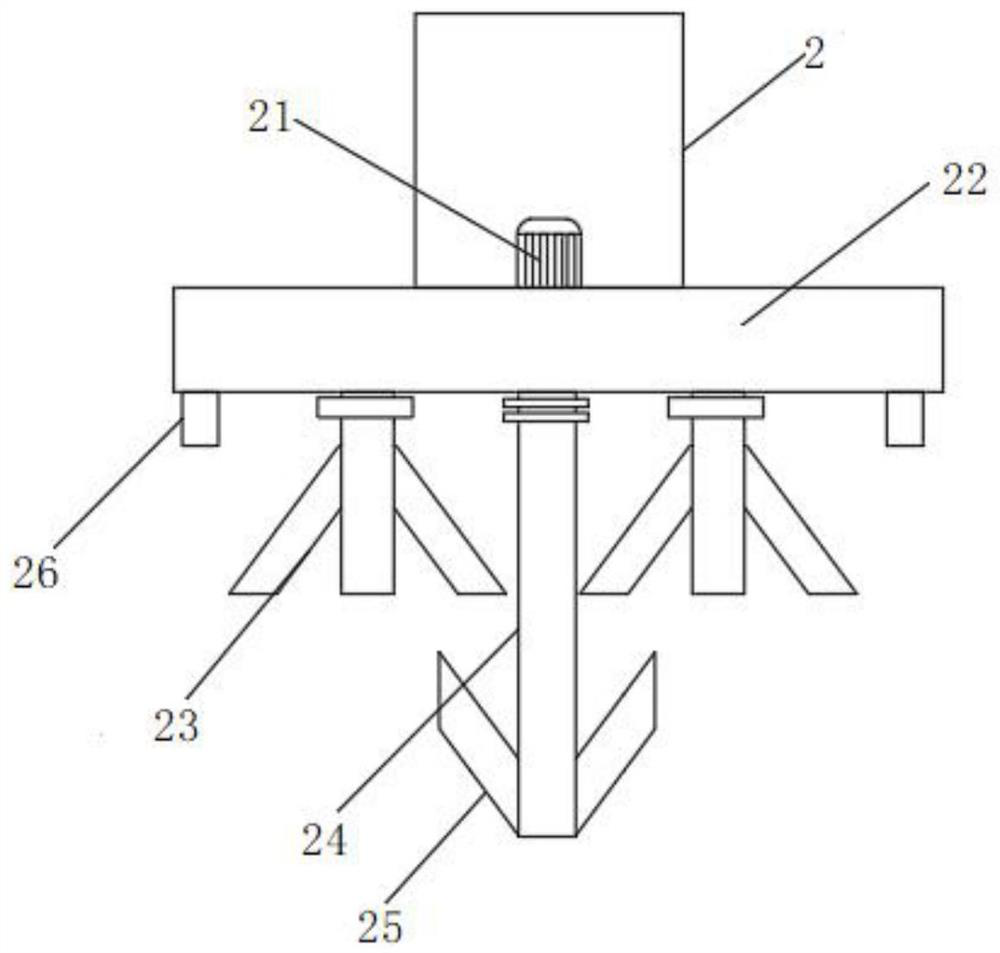

[0041] see Figure 1-7 Shown, wherein, the specific preparation steps of the fertilizer in above-mentioned embodiment 1-2 are as follows:

[0042] Step 1. Put pond ditch mud, oil shale ash, ferrous sulfate, monoammonium phosphate, manganese sulfate, potassium chloride, zinc sulfate, potassium magnesium sulfate fertilizer, ammonium molybdate and attapulgite powder in a mixer and mix evenly to obtain Material A;

[0043] Step 2: adding animal hair to 15-23% sulfuri...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com