Synthesis process of high-quality span-80

A synthesis process and technology of Span, which is applied in the field of synthesis process of high-quality Span 80, can solve the problems of difficult application, low solubility, toxicity, etc., and achieve the effect of simplified process and good quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

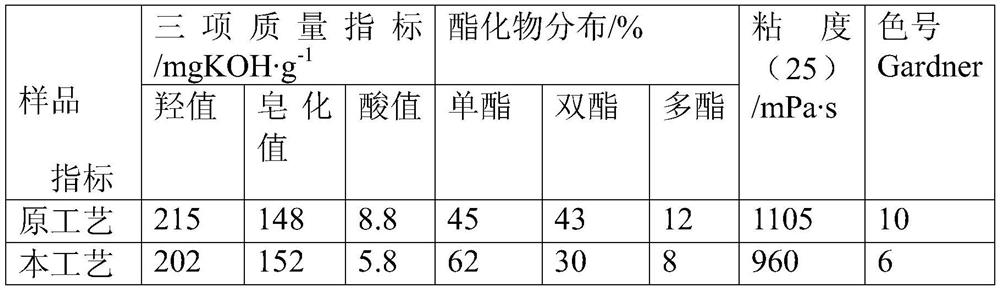

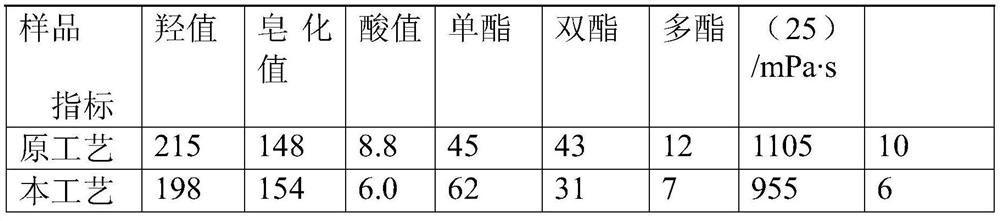

Examples

specific Embodiment 1

[0029] A kind of synthetic technique of high-quality Span 80, comprises the steps:

[0030] (1) Weigh 10g of anhydrous sorbitol powder and 0.1g of etherification catalyst AlCl 3 Carry out the etherification reaction at 150°C under vacuum (vacuum degree not less than 0.096MPa) and nitrogen protection, and take samples to measure the hydroxyl value after reacting for 120 minutes;

[0031] (2) When the hydroxyl value is at 1300-1400mgKOH / g, add 25g oleic acid (the molar ratio of anhydrous sorbitol to oleic acid is 1:1.61) and 0.2g esterification catalyst Z 2 (esterification catalyst Z 2 by NaOH and Na 2 CO 3 composition, the mass ratio of the two is 5:2) the esterification reaction is also carried out at 200°C under vacuum and nitrogen protection, and the acid value is measured by sampling after 150 minutes of reaction;

[0032] (3) When the acid value is less than or equal to 7mgKOH / g, stop the reaction, then cool down with cooling water, and stop vacuuming when the temperat...

specific Embodiment 2

[0039] A kind of synthetic technique of high-quality Span 80, comprises the steps:

[0040] (1) Weigh 10g of anhydrous sorbitol powder and 0.12g of etherification catalyst AlCl 3 Carry out the etherification reaction at 150°C under vacuum (vacuum degree not less than 0.096MPa) and nitrogen protection, and take samples to measure the hydroxyl value after reacting for 90 minutes;

[0041] (2) When the hydroxyl value is at 1300-1400mgKOH / g, add 25g oleic acid (the molar ratio of anhydrous sorbitol to oleic acid is 1:1.61) and 0.24g esterification catalyst Z 2 (esterification catalyst Z 2 by NaOH and Na 2 CO 3 composition, the mass ratio of the two is 5:2) the esterification reaction is also carried out at 200°C under vacuum and nitrogen protection, and the acid value is measured by sampling after 150 minutes of reaction;

[0042] (3) When the acid value is less than or equal to 7mgKOH / g, stop the reaction, then cool down with cooling water, and stop vacuuming when the tempera...

specific Embodiment 3

[0050] A kind of synthetic technique of high-quality Span 80, comprises the steps:

[0051] (1) Weigh 10g anhydrous sorbitol powder and 0.15g etherification catalyst ZnCl 2 Carry out the etherification reaction at 150°C under vacuum (vacuum degree not less than 0.096MPa) and nitrogen protection, and take samples to measure the hydroxyl value after reacting for 150 minutes;

[0052] (2) When the hydroxyl value is at 1300-1400mgKOH / g, add 25g oleic acid (the molar ratio of anhydrous sorbitol to oleic acid is 1:1.61) and 0.3g esterification catalyst Z 2 (esterification catalyst Z 2 by NaOH and Na 2 CO 3 composition, the mass ratio of the two is 5:2) the esterification reaction is also carried out at 200°C under vacuum and nitrogen protection, and the acid value is measured by sampling after 150 minutes of reaction;

[0053] (3) When the acid value is less than or equal to 7mgKOH / g, stop the reaction, then cool down with cooling water, and stop vacuuming when the temperature i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com