Preparation method of antibacterial degradable food packaging film material

A food packaging film and slurry technology, which is applied in packaging, wrapping paper, transportation and packaging, etc., can solve the problems of food packaging film environmental pollution, etc., and achieve the effect of excellent antibacterial performance, easy operation and good storage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

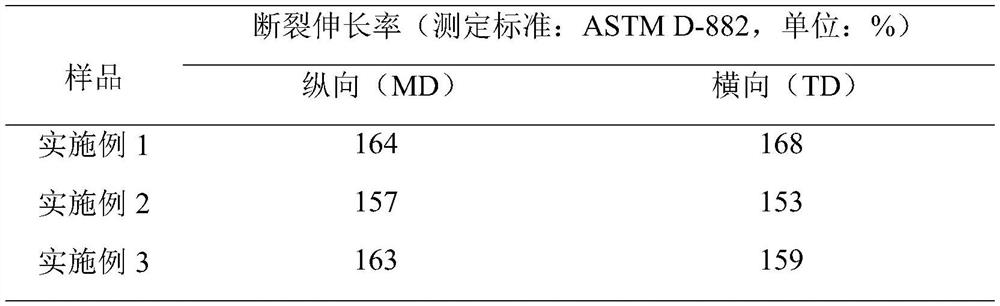

Examples

Embodiment 1

[0035] A preparation method of an antibacterial and degradable food packaging film material, comprising the following steps:

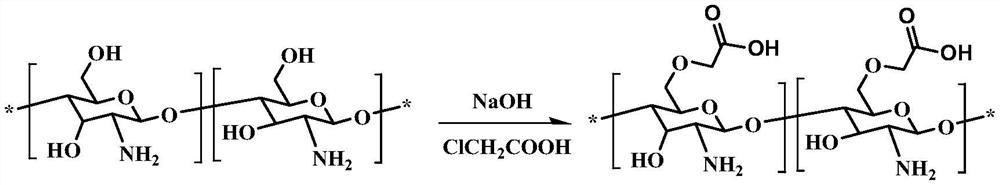

[0036] (1) Preparation of carboxylated chitosan (CMCS)

[0037] 5g low molecular weight chitosan is placed in 50mL NaOH-isopropanol solution (6g NaOH is dissolved in 90% isopropanol) for swelling, and is activated by alkali at 40°C for 1h. A solution of 6.5 g of chloroacetic acid dissolved in isopropanol (10 mL) was added dropwise to the separatory funnel. Stir at 40°C for 4h. Precipitate is soaked in 200mL ethanol (80%) for 0.5h, hydrochloric acid adjusts the pH value to 7.0, and the product is washed with absolute ethanol and vacuum-filtered, and vacuum-dried at 60°C to obtain the product carboxylated chitosan (CMCS).

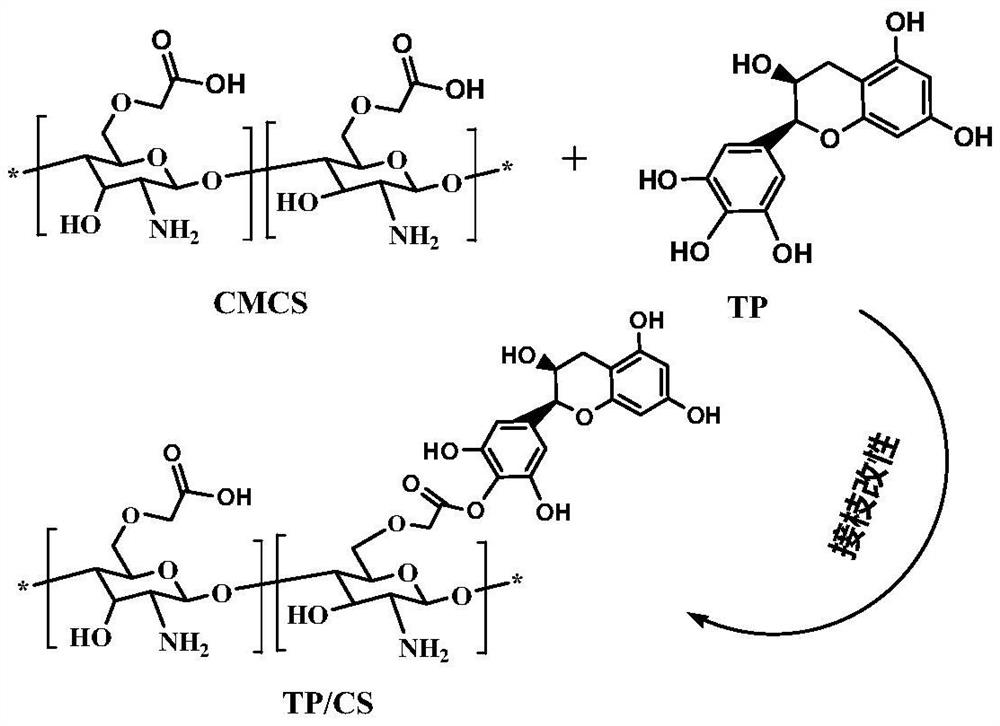

[0038] (2) Preparation of tea polyphenol grafted chitosan composite (TP / CS)

[0039] Dissolve 1g carboxylated chitosan CMCS prepared in step (1) in 1% 100mL acetic acid solution, stir and dissolve at room temperature; weigh 0.25g t...

Embodiment 2

[0043] A preparation method of an antibacterial and degradable food packaging film material, comprising the following steps:

[0044] (1) Preparation of carboxylated chitosan (CMCS)

[0045] 10g of low molecular weight chitosan was swelled in 100mL NaOH-isopropanol solution (13g NaOH dissolved in 90% isopropanol), and activated with alkali at 45°C for 1.5h. A solution of 15 g of chloroacetic acid dissolved in isopropanol (20 mL) was added dropwise to the separatory funnel. Stir at 40°C for 4h. The precipitate was soaked in 200mL ethanol (80%) for 0.5h, the pH value was adjusted to 7.0 with hydrochloric acid, the product was washed with absolute ethanol and vacuum filtered, and vacuum-dried at 60°C to obtain the product carboxylated chitosan (CMCS).

[0046] (2) Preparation of tea polyphenol grafted chitosan composite (TP / CS)

[0047] Dissolve 5g of carboxylated chitosan CMCS prepared in step (1) in 2% 100mL acetic acid solution, stir and dissolve at room temperature; weigh ...

Embodiment 3

[0051] A preparation method of an antibacterial and degradable food packaging film material, comprising the following steps:

[0052] (1) Preparation of carboxylated chitosan (CMCS)

[0053] 1g of low molecular weight chitosan was swelled in 10mL NaOH-isopropanol solution (1.4g NaOH dissolved in 90% isopropanol), and activated with alkali at 40°C for 1h. A solution of 1.5 g of chloroacetic acid dissolved in isopropanol (5 mL) was added dropwise to a separatory funnel. Stir at 40°C for 4h. The precipitate was soaked in 50mL ethanol (80%) for 0.5h, the pH value was adjusted to 7.0 with hydrochloric acid, the product was washed with absolute ethanol and vacuum filtered, and vacuum-dried at 60°C to obtain the product carboxylated chitosan (CMCS).

[0054] (2) Preparation of tea polyphenol grafted chitosan composite (TP / CS)

[0055]Dissolve 1g carboxylated chitosan CMCS prepared in step (1) in 1% 100mL acetic acid solution, stir and dissolve at room temperature; weigh 0.30g tea ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com