Antibacterial composite material and preparation method and application thereof

A technology of composite materials and antibacterial agents, applied in the field of polymer composite materials, can solve problems such as harm to health, three-proof shells are easily contaminated with various bacteria, etc., and achieve the effects of excellent antibacterial properties, protection of human health, and good mechanical properties.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0052] One embodiment of the present invention also provides a preparation method of antibacterial composite material, please refer to the attached figure 1 , including the following steps S100-S200.

[0053] Step S100, providing raw materials.

[0054] The above-mentioned raw materials include 95% to 99% polymer resin by weight percentage, 0.5% to 1.5% inorganic silver antibacterial agent and 0.1% to 3% dyeing agent; and the polymer resin is selected from at least one of polyurethane resin and polycarbonate resin kind.

[0055] Step S200, mixing the above-mentioned raw materials and injecting to obtain an antibacterial composite material.

[0056] In some of these embodiments, in step S200, injection molding includes a heating and melting stage and an injection molding stage; further, the raw material is heated to a molten state through the heating stage, and then injected into the mold through the nozzle of the injection molding machine, and the time of the injection moldi...

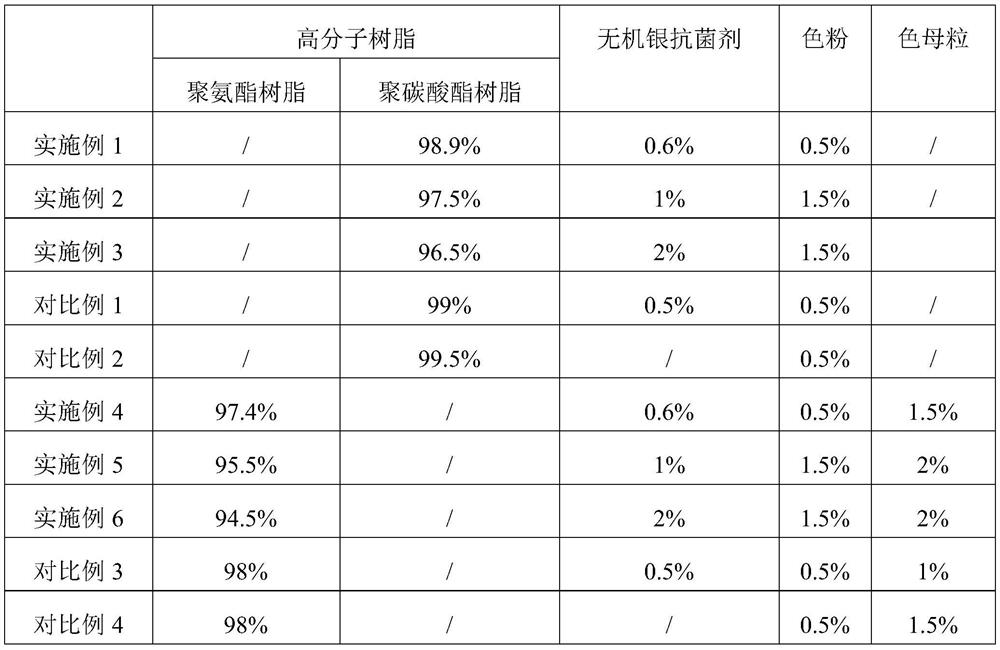

Embodiment 1

[0075] 1) By weight percentage, weigh 98.9% polycarbonate resin, 0.6% inorganic silver antibacterial agent, 0.5% toner, mix and stir the raw materials for 5 minutes, then dry at 90° C. for 3 hours in a dryer to obtain a mixture.

[0076] 2) Put the mixed material into the injection molding machine, adjust the nozzle and screw temperature of the injection molding machine to 300°C, use the mobile phone shell mold for 50 seconds to mold, cool to room temperature, and obtain an antibacterial composite material cover, and then contact the obtained cover Paste the polyethylene terephthalate protective film with self-adhesive 3M adhesive on one side of the electronic product to the inside of the PC cover to obtain the finished antibacterial cover.

Embodiment 2

[0078] 1) By weight percentage, weigh 97.5% polycarbonate resin, 1% inorganic silver antibacterial agent, 1.5% toner, mix and stir the raw materials for 5 minutes, then dry at 90° C. for 3 hours in a dryer to obtain a mixture.

[0079] 2) Put the mixed material into the injection molding machine, adjust the nozzle and screw temperature of the injection molding machine to 300°C, use the mobile phone shell mold for 50 seconds to mold, cool to room temperature, and obtain an antibacterial composite material cover, and then contact the obtained cover Paste the polyethylene terephthalate protective film with self-adhesive 3M adhesive on one side of the electronic product to the inside of the PC cover to obtain the finished antibacterial cover.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com