Heat-resistant silicone rubber insulated cable

A silicone rubber insulation and cable technology, applied in rubber insulators, organic insulators and other directions, can solve the problems of hidden safety hazards, inability to meet, low heat resistance of cables, etc., to achieve faster material flow, improve stirring efficiency, and excellent high temperature resistance. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

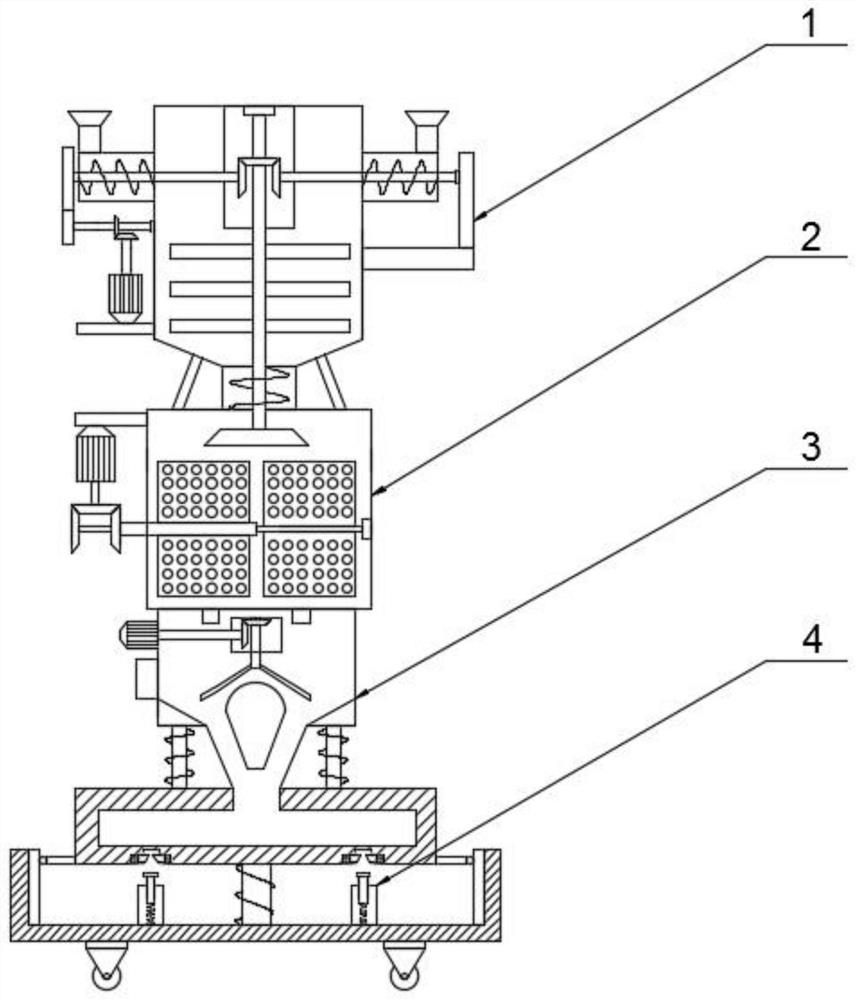

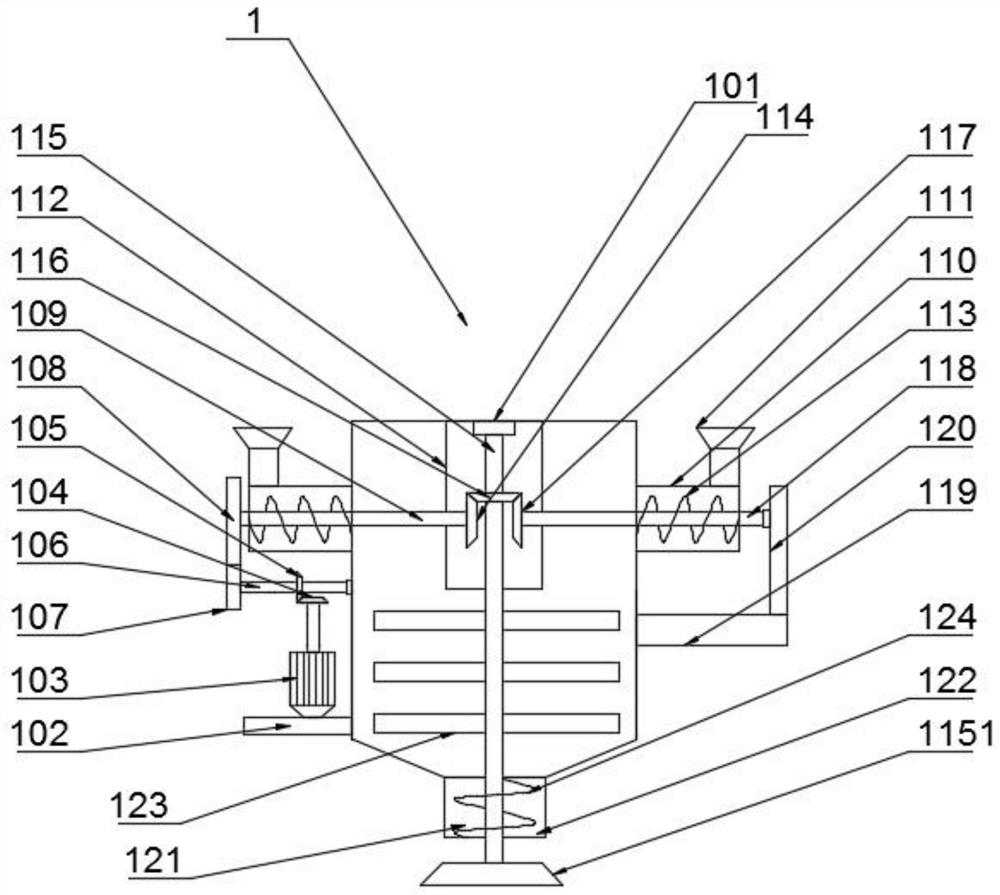

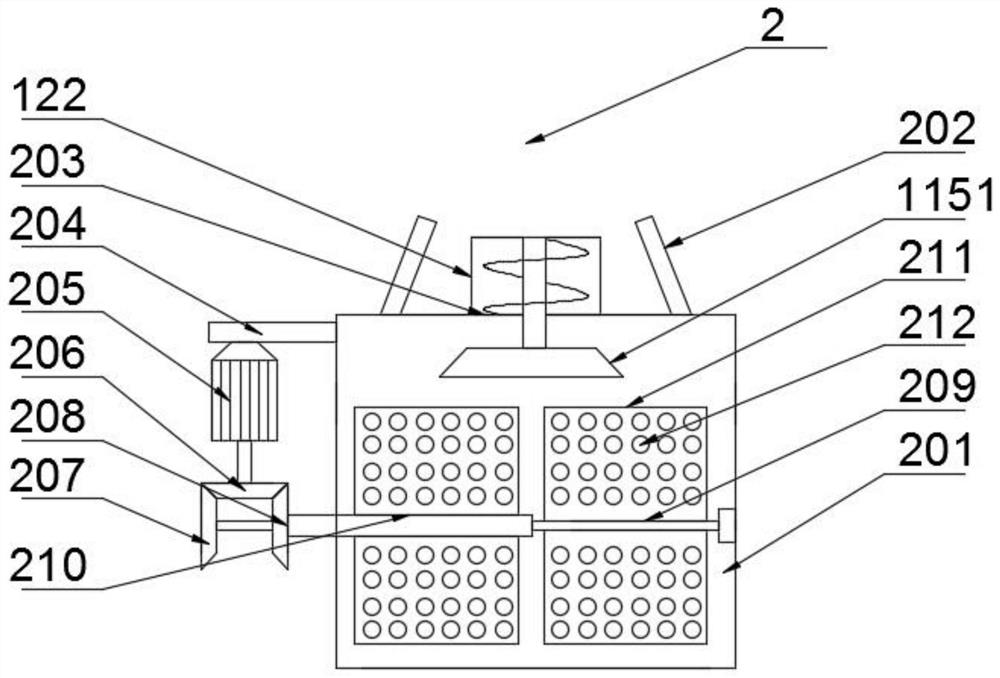

Image

Examples

Embodiment 1

[0041] A heat-resistant silicone rubber insulated cable, made of the following raw materials in parts by weight: 20 parts of polypropylene resin, 40 parts of methyl vinyl silicone rubber, 10 parts of ethylene-vinyl acetate, 5 parts of styrene-based elastomer, lemon 5 parts of tributyl acetate, 1 part of methyl 2,2-dithienyl glycolate, 10 parts of fumed silica, 15 parts of precipitated silica, 80 parts of modified halloysite nanotubes, structure control agent 8 parts, 1 part of accelerator DM and 8 parts of insulation additive;

[0042] The heat-resistant silicone rubber insulated cable is made by the following steps:

[0043] The first step, adding polypropylene resin, methyl vinyl silicone rubber, ethylene-vinyl acetate and styrene-based elastomer into a mixing and stirring device for mixing and stirring, to obtain a mixed material A;

[0044] The second step is to add tributyl citrate, methyl 2,2-dithienyl glycolate, fumed silica, precipitated silica, modified halloysite na...

Embodiment 2

[0053] A heat-resistant silicone rubber insulated cable, made of the following raw materials in parts by weight: 25 parts of polypropylene resin, 60 parts of methyl vinyl silicone rubber, 12 parts of ethylene-vinyl acetate, 7 parts of styrene-based elastomer, lemon 7 parts of tributyl acetate, 2 parts of methyl 2,2-dithienyl glycolate, 20 parts of fumed silica, 25 parts of precipitated silica, 110 parts of modified halloysite nanotubes, structure control agent 9 parts, 2 parts of accelerator DM and 11 parts of insulation additives; the heat-resistant silicone rubber insulated cable is made by the following steps:

[0054] The first step, adding polypropylene resin, methyl vinyl silicone rubber, ethylene-vinyl acetate and styrene-based elastomer into a mixing and stirring device for mixing and stirring, to obtain a mixed material A;

[0055] The second step is to add tributyl citrate, methyl 2,2-dithienyl glycolate, fumed silica, precipitated silica, modified halloysite nanotub...

Embodiment 3

[0064] A heat-resistant silicone rubber insulated cable, made of the following raw materials in parts by weight: 30 parts of polypropylene resin, 80 parts of methyl vinyl silicone rubber, 15 parts of ethylene-vinyl acetate, 12 parts of styrene-based elastomer, lemon 10 parts of tributyl acetate, 3 parts of methyl 2,2-dithienyl glycolate, 25 parts of fumed silica, 30 parts of precipitated silica, 160 parts of modified halloysite nanotubes, structure control agent 15 parts, 3 parts of accelerator DM and 14 parts of insulation additive;

[0065] The heat-resistant silicone rubber insulated cable is made by the following steps:

[0066] The first step, adding polypropylene resin, methyl vinyl silicone rubber, ethylene-vinyl acetate and styrene-based elastomer into a mixing and stirring device for mixing and stirring, to obtain a mixed material A;

[0067] The second step is to add tributyl citrate, methyl 2,2-dithienyl glycolate, fumed silica, precipitated silica, modified halloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com