Soft reticulated polyurethane composite material and preparation method thereof

A composite material and polyurethane technology, applied in the field of polyurethane materials, can solve the problems of low flame retardant performance, poor aging resistance, and inability to achieve, and achieve the effects of avoiding direct irradiation, improving flame retardancy, and improving aging resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

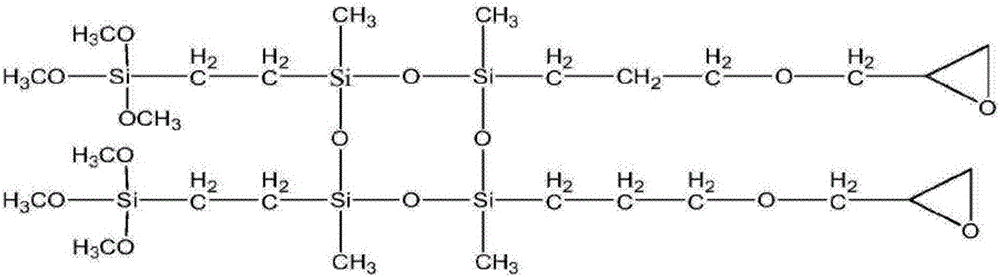

Image

Examples

preparation example Construction

[0044] The preparation method of soft reticular polyurethane composite material of the present invention comprises the following steps:

[0045] Pretreatment of soft reticulated polyurethane aimed at increasing its surface adhesion;

[0046] Covering the raw material of the silica gel material with the soft reticular polyurethane, and prepolymerizing the raw material of the silica gel material to obtain a prepolymer composite material;

[0047] Vulcanizing the prepolymer composite

[0048] The above-mentioned pretreatment aimed at increasing its surface adhesion can be as follows: polyethylene glycol is applied to the surface of the polyurethane product, and then the polyurethane product applied with polyethylene glycol is placed in a plasma generating device for plasma gas surface modification. For permanent treatment, set the power of the plasma generator to 10-1500w, and the treatment time is 0.5-120min, and then wash the polyurethane products that have undergone plasma ga...

Embodiment 1

[0052] The preparation method of soft reticular polyurethane composite material of the present invention comprises the following steps:

[0053] (1), the prepared soft reticular polyurethane material is processed, the treatment includes desulfurization, deodorization and pretreatment aimed at improving the surface adhesion of the soft reticular polyurethane material);

[0054] (2), preparing silicone rubber for compounding (place 70 parts of silica gel, 10 parts of flame retardant, 1 part of catalyst, 1 part of adhesive and 0.2 part of defoamer in a premixed reactor and mix well);

[0055] (3) Pump the silicone rubber material mixed in the reaction kettle into the trough of the compound equipment, and enter the soft mesh polyurethane material through the entrance of the compound equipment, so that the silicone rubber material is evenly and completely compounded (surface covered) on the mesh on polyurethane material;

[0056] (4) Prepolymerize the compounded product for 2 hour...

Embodiment 2

[0059] (1), the prepared soft reticular polyurethane material is processed, the treatment includes desulfurization, deodorization and pretreatment aimed at improving the surface adhesion of the soft reticular polyurethane material);

[0060] (2), preparing silicone rubber for compounding (place 90 parts of silica gel, 20 parts of flame retardant, 2 parts of catalyst, 3 parts of adhesive and 0.8 part of defoamer in a premixed reactor and mix well);

[0061] (3) Pump the silicone rubber material mixed in the reaction kettle into the trough of the compound equipment, and enter the soft mesh polyurethane material through the entrance of the compound equipment, so that the silicone rubber material is evenly and completely compounded (surface covered) on the mesh on polyurethane material;

[0062] (4), pre-polymerize the compounded product for 6 hours according to the characteristic requirements;

[0063] (5) Finally, it enters the vulcanization equipment, and a new type of composi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com