Water-based conductive adhesive and preparation method thereof

A conductive adhesive, water-based technology, applied in the field of conductive adhesive, can solve the problems of inapplicability, connection of sensitive electronic components and bioelectronic applications, limitation of the application range of conductive adhesive, and poisonous conductive adhesive, and achieve high conductivity and high The effect of adhesion ability and large ductility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

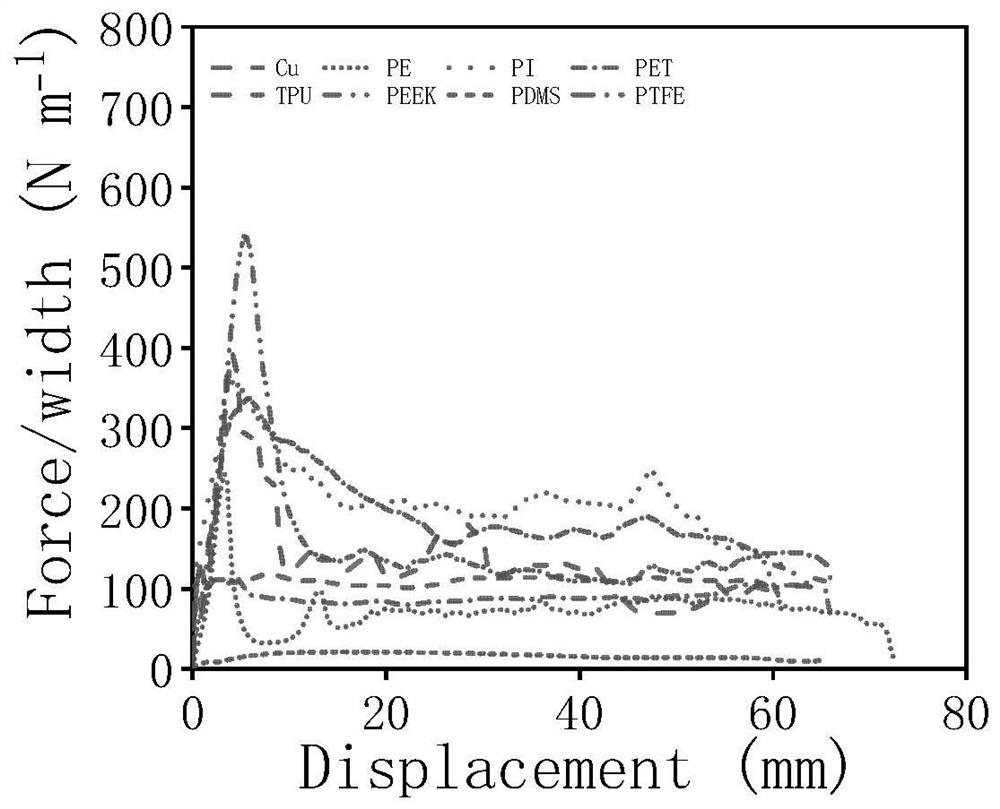

[0060] Preparation of conductive adhesive: Take 100g of polyvinyl alcohol, 1000g of citric acid, 950g of sorbitol and 50g of PEDOT:PSS and add them to 8000g of water respectively, fully stir and dissolve, transfer the mixed solution into a mold and heat and dry at 60 degrees Celsius. Utilize the conductive adhesive obtained in this embodiment to be coated on different substrates of copper (Cu), aluminum (Al), PE, PI, PET, TPU, PEEK, PDMS, PTFE to test the adhesion, and the conductive adhesive on each substrate Adhesion as figure 1 shown, from figure 1 It can be seen that the conductive adhesive can be stably bonded on different substrate materials.

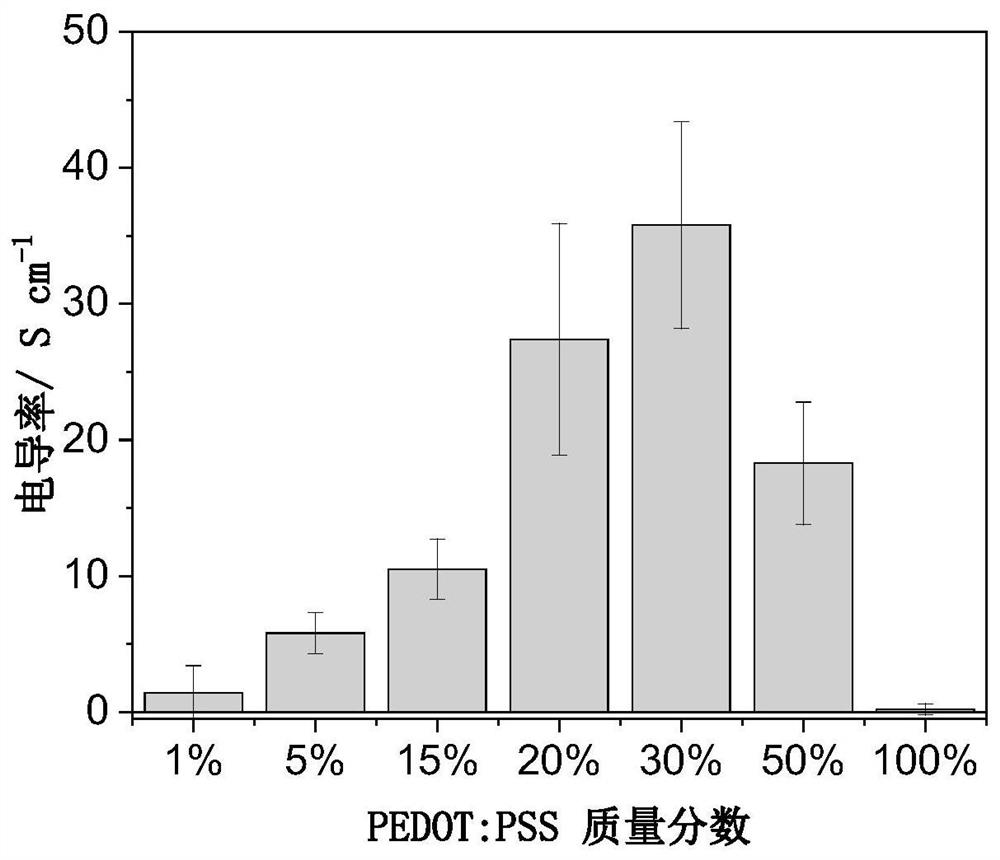

[0061] Other conditions remain the same, only the mass fraction of PEDOT:PSS is changed, and the mass fraction of PEDOT:PSS is 1%, 5%, 10%, 15%, 20%, 30% and 50%, respectively, to obtain conductive adhesives with different conductivity, and the obtained The conductivity of the conductive adhesive is as figure 2 shown.

Embodiment 2

[0063] Preparation of conductive adhesive: Take 50g of polyacrylic acid, 1000g of malic acid, 900g of pentaerythritol and 50g of PEDOT:PSS and add them to 8000g of water respectively, fully stir and dissolve, transfer the mixed solution into a mold and heat and dry at 60 degrees Celsius.

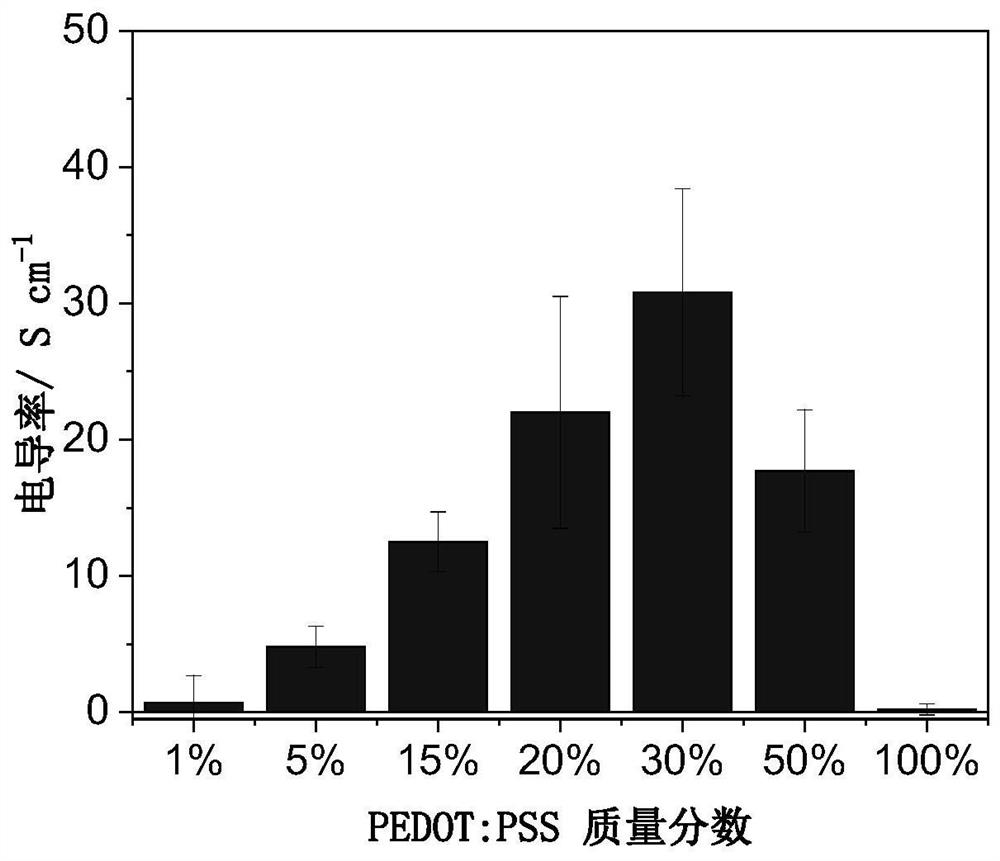

[0064] Other conditions remain the same, only the mass fraction of PEDOT:PSS is changed, and the mass fraction of PEDOT:PSS is 1%, 5%, 10%, 15%, 20%, 30% and 50%, respectively, to obtain conductive adhesives with different conductivity, and the obtained The conductivity of the conductive adhesive is as image 3 shown.

Embodiment 3

[0066] Preparation of conductive adhesive: Take 100g of polyvinyl alcohol, 1000g of tartaric acid, 650g of cyclodextrin and 50g of PEDOT:PSS and add them to 8000g of water respectively, fully stir and dissolve, transfer the mixed solution into a mold and heat and dry at 60 degrees Celsius.

[0067] Other conditions remain the same, only the mass fraction of PEDOT:PSS is changed, and the mass fraction of PEDOT:PSS is 1%, 5%, 10%, 15%, 20%, 30% and 50%, respectively, to obtain conductive adhesives with different conductivity, and the obtained The conductivity of the conductive adhesive is as Figure 4 shown.

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap