High-plasticity easy-to-process cobalt-based deformation high-temperature alloy and preparation method thereof

A deformable superalloy and easy-to-process technology, which is applied in the field of high-plasticity and easy-to-process cobalt-based deformed superalloy and its preparation, can solve the problems of low yield and long process flow, etc., to improve plasticity, solve long process flow, and improve cooling. Effect of hot workability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

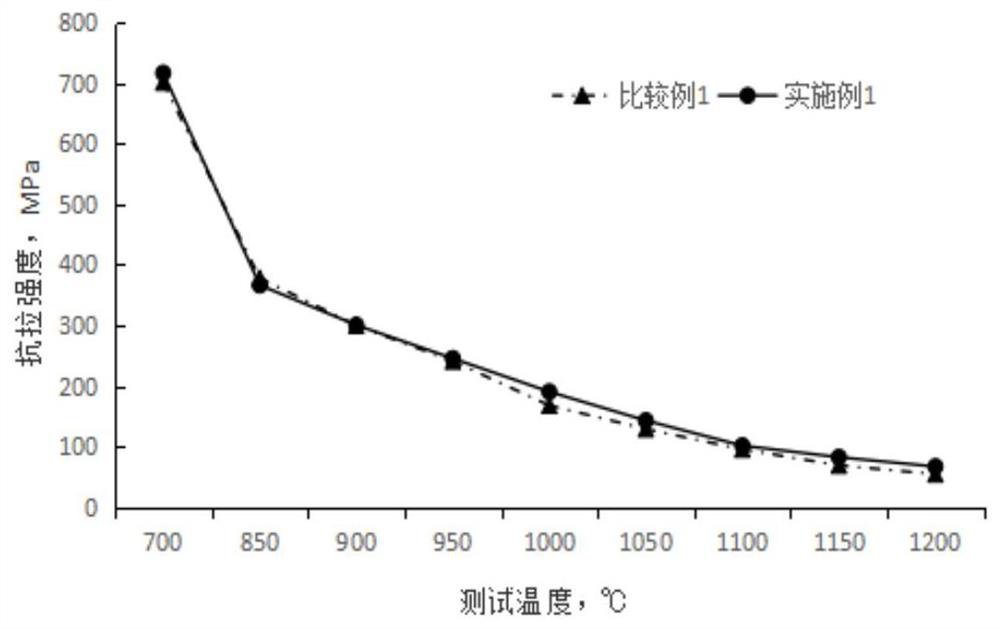

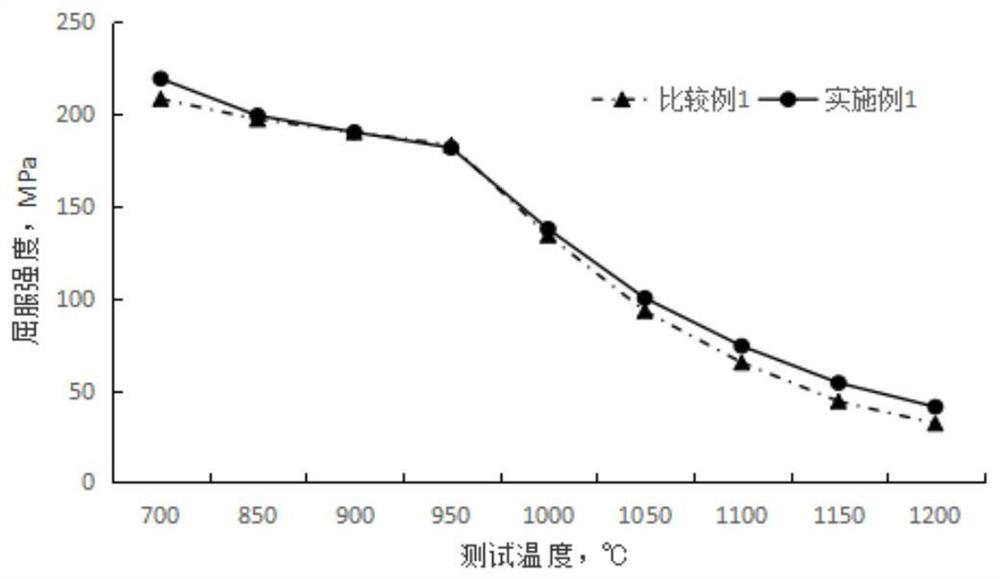

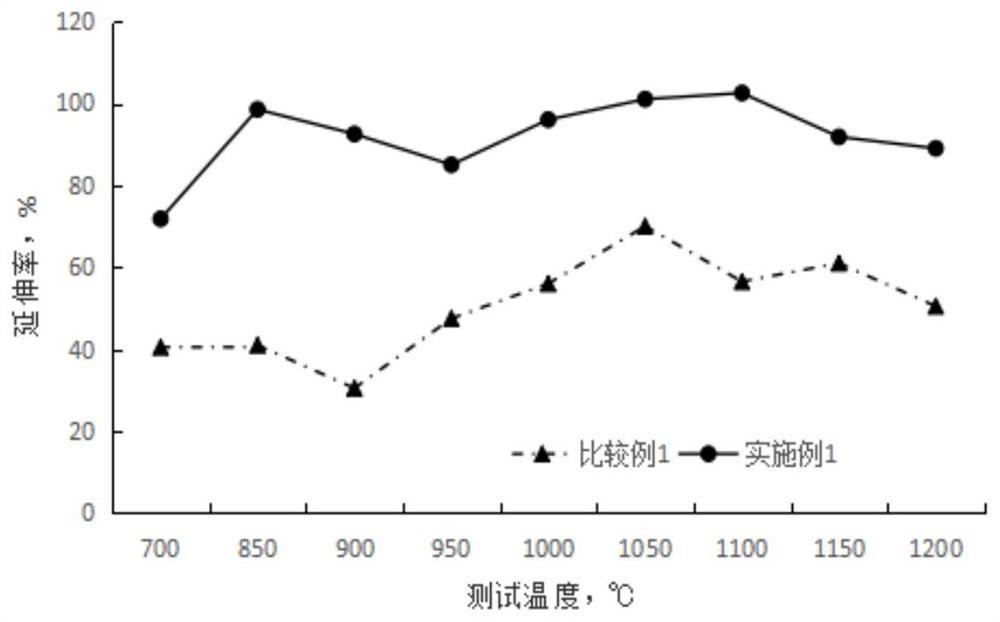

Examples

Embodiment 1

[0029] A highly plastic and easy-to-process cobalt-based deformed superalloy and a preparation method thereof, select raw materials with satisfactory purity, including Co, C, Cr, Ni, W, Mn, Fe, Al, Y and unavoidable impurities. In the vacuum induction furnace, the raw materials are melted, refined, and the electrode rods are poured to complete the vacuum induction furnace smelting; the cast electrode rods are used for electroslag remelting and smelting, and the diameter of the electroslag ingot is 150mm. The mass percentages of each element and impurity elements are shown in Table 1.

[0030] The electroslag ingot is subjected to diffusion annealing, the annealing temperature is 1200°C, the time is 20h, and air-cooled after heat preservation. The forging temperature range is 910-1010°C, and it is formed by one-fire forging. . The cold drawing deformation is controlled within the range of 49-60%, the heat treatment temperature is 1180-1200°C, the holding time is 5-120 minutes...

Embodiment 2

[0033] A highly plastic and easy-to-process cobalt-based deformed superalloy and a preparation method thereof, select raw materials with satisfactory purity, including Co, C, Cr, Ni, W, Mn, Fe, Al, Y and unavoidable impurities. In the vacuum induction furnace, the raw materials are melted, refined, and the electrode rods are poured to complete the vacuum induction furnace smelting; the cast electrode rods are used for electroslag remelting and smelting, and the diameter of the electroslag ingot is 350mm. The mass percentages of each element and impurity elements are shown in Table 1.

[0034] The electroslag ingot is subjected to diffusion annealing, the annealing temperature is 1230°C, the time is 50h, and air-cooled after heat preservation. The forging temperature range is 1180-1230°C, and it is formed by one-fire forging. The forging specification is 80×250mm, and then hot-rolled. The hot-rolling temperature range is 1200-1250°C. ×250mm.

[0035] The cold rolling deformat...

Embodiment 3

[0038] A highly plastic and easy-to-process cobalt-based deformed superalloy and a preparation method thereof, select raw materials with satisfactory purity, including Co, C, Cr, Ni, W, Mn, Fe, Al, Y and unavoidable impurities. In the vacuum induction furnace, the raw materials are melted, refined, and the electrode rods are poured to complete the vacuum induction furnace smelting; the cast electrode rods are used for electroslag remelting and smelting. For an electroslag ingot with a diameter of 250mm, the mass percentage of each element and impurity elements is shown in Table 1.

[0039] The electroslag ingot is subjected to diffusion annealing, the annealing temperature is 1200°C, the time is 30h, and air-cooled after heat preservation. The forging temperature range is 1120-1180°C, and it is formed by one-fire forging. The forging specification is 80×80mm, and then hot-rolled. The hot-rolling temperature range is 1100-1150°C. It is formed by one-fire hot-rolling. .

[004...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com