Application of improved PP (polypropylene) to melt-blown fabric

A melt-blown cloth and melt technology, which is applied in the directions of non-woven fabrics, melt spinning, spinneret assemblies, etc., can solve problems such as difficult to buy, and achieve the effect of blocking viruses

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] As a preferred embodiment, the extruder is composed of a transmission, a feeding device, a barrel, a screw, a head and a die, and the extruder is divided into a solid delivery zone, a melting zone and a melt delivery zone; Step 1 The compound in the process is mixed with a high-speed rotary mixer, so that the melt is mixed and mixed, and then enters the extruder for melting to complete the melt feeding and discharging operations.

Embodiment 2

[0043] As a preferred embodiment, the diameter of the screw gradually increases from the fixed conveying area to the melt conveying area, and the aspect ratio of the screw is greater than 28, so that the melt has a certain reflux when the screw is extruded, which plays a role in mixing. The heating uniformity will be improved.

Embodiment 3

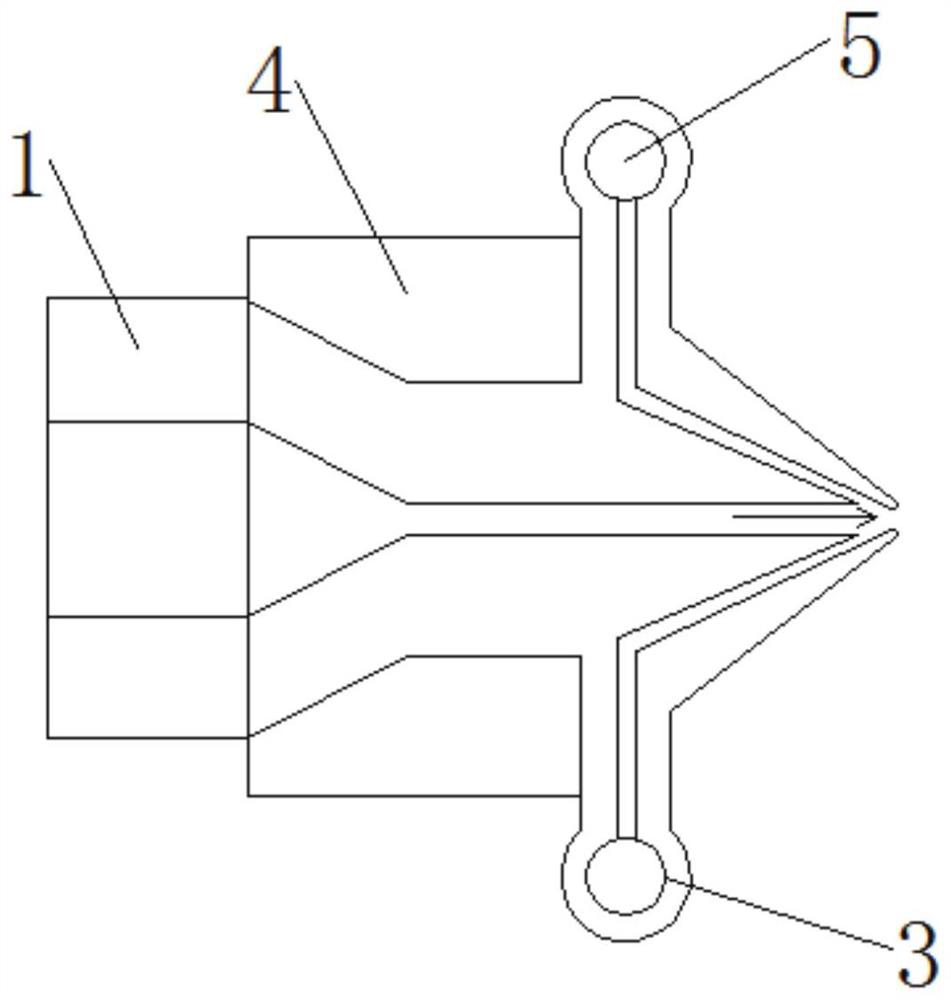

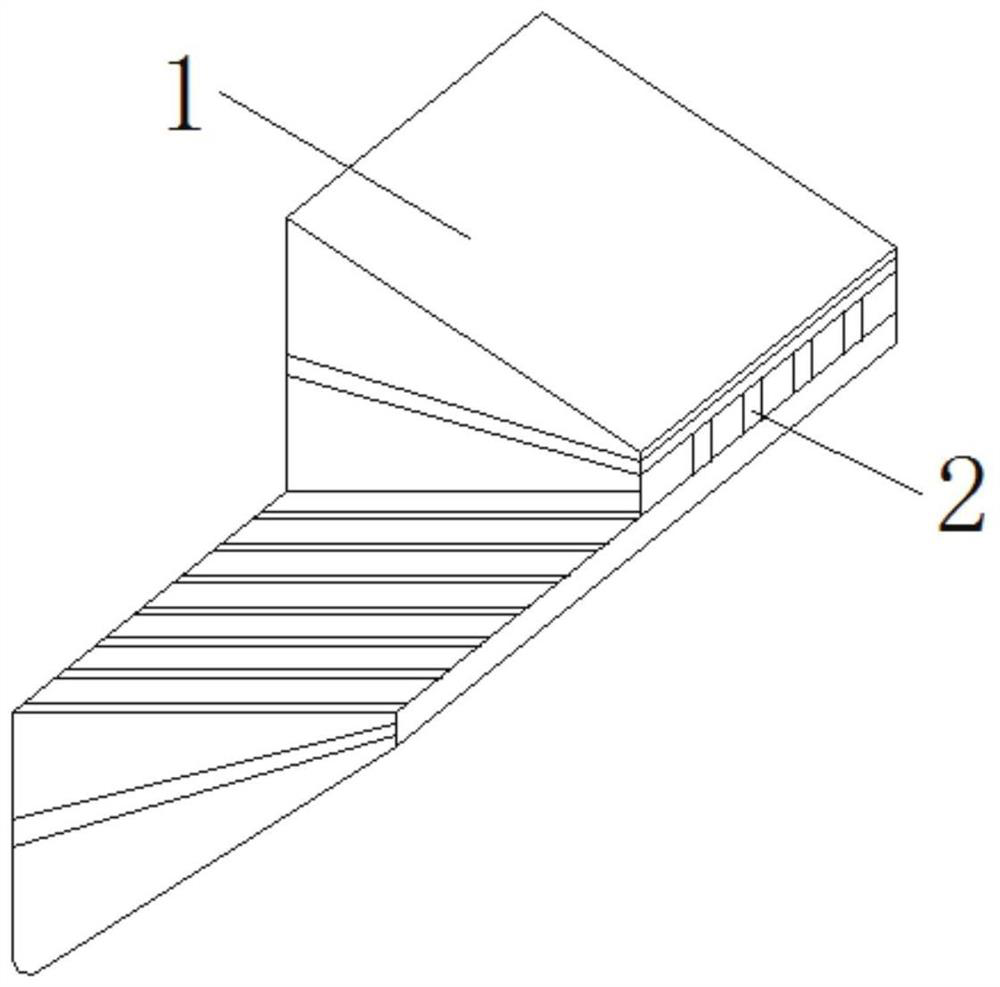

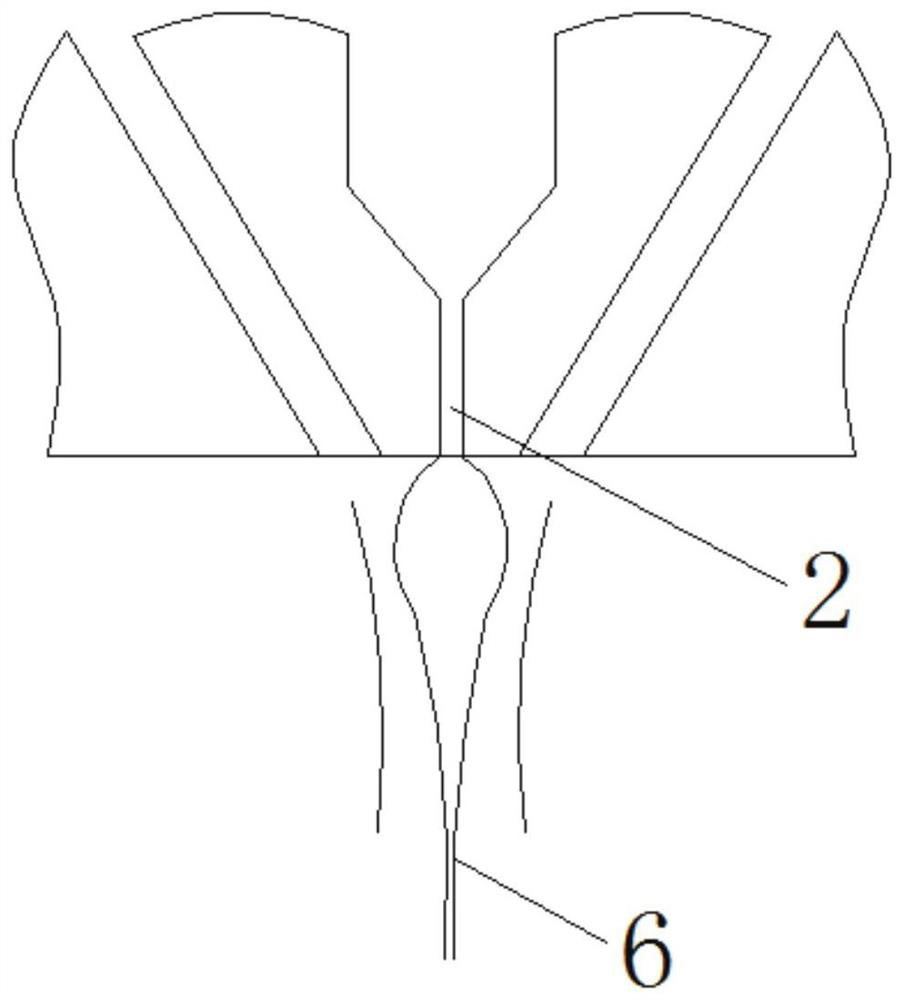

[0045] As a preferred embodiment, the melting die head assembly 1 includes a polymer distribution system, a die head system, a drafting hot air pipeline channel 3 and a heating and heat preservation element 4, at the same temperature, screw speed and receiving distance (DCD) Under the same conditions, the faster the hot air speed, the smaller the fiber diameter, the softer the non-woven fabric will gradually become, and the more fibers will be entangled, resulting in a denser and smoother fiber web with increased strength, allowing the melt to complete the melt-blown process. So that the improved PP has 35% filtration performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com