Three-stage rose drying system and drying device thereof

A technology of drying device and drying barrel, which is applied in the direction of drying, drying machine, drying gas arrangement, etc., to achieve the effect of good rehydration, less loss of nutrients, and no noise pollution

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

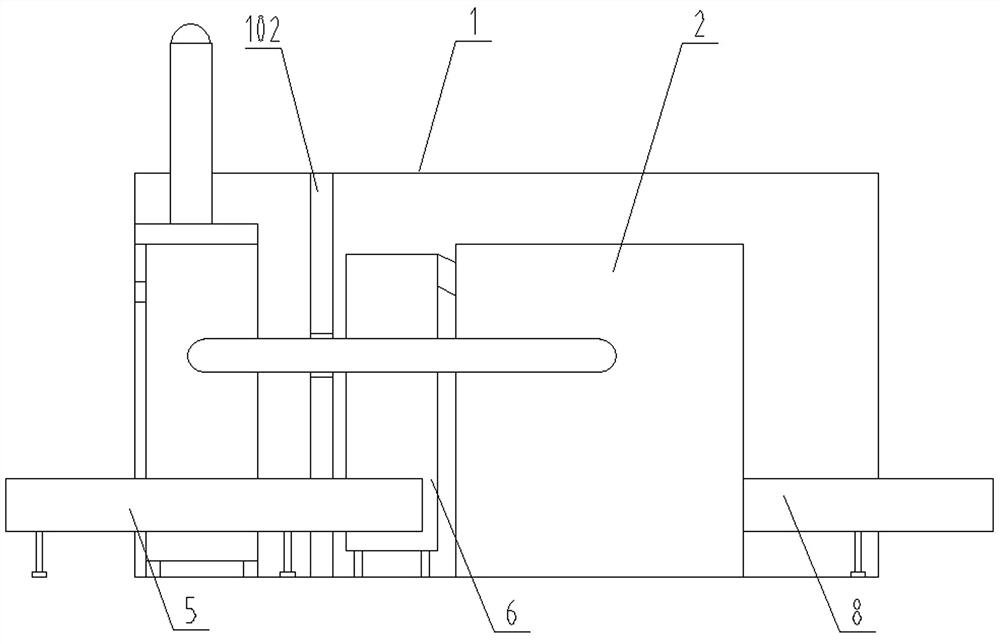

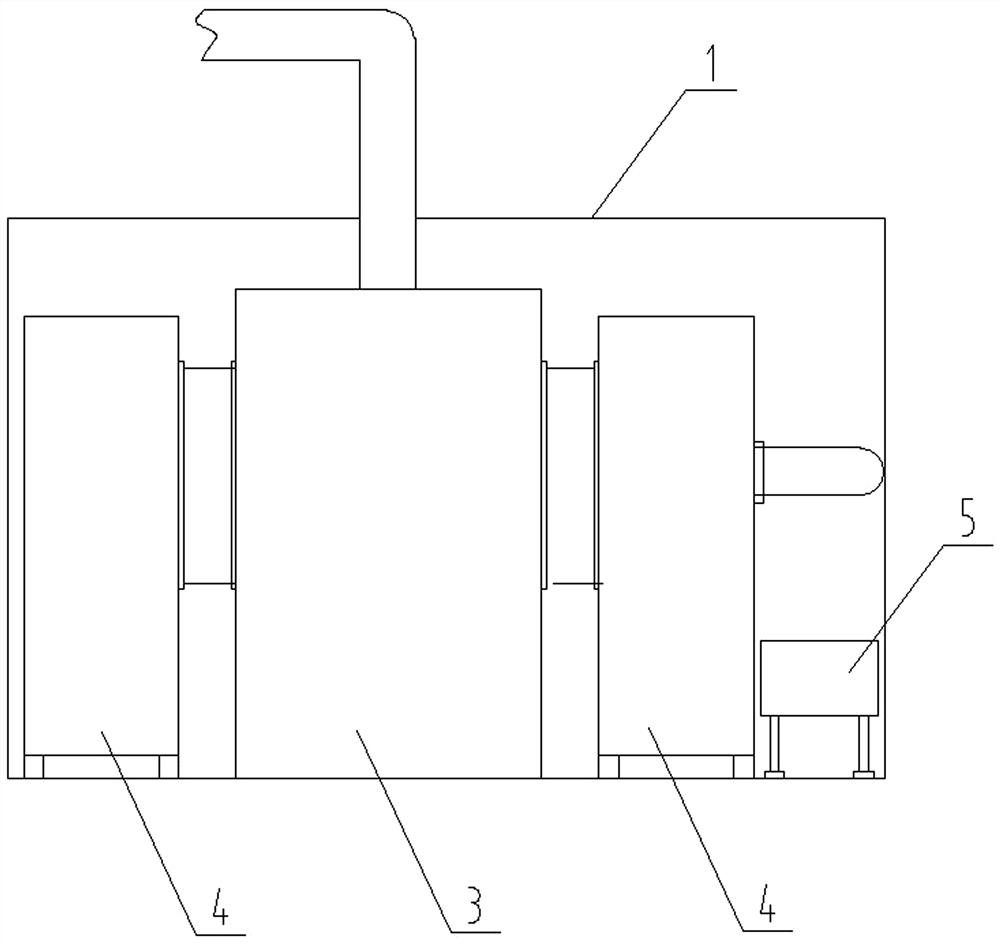

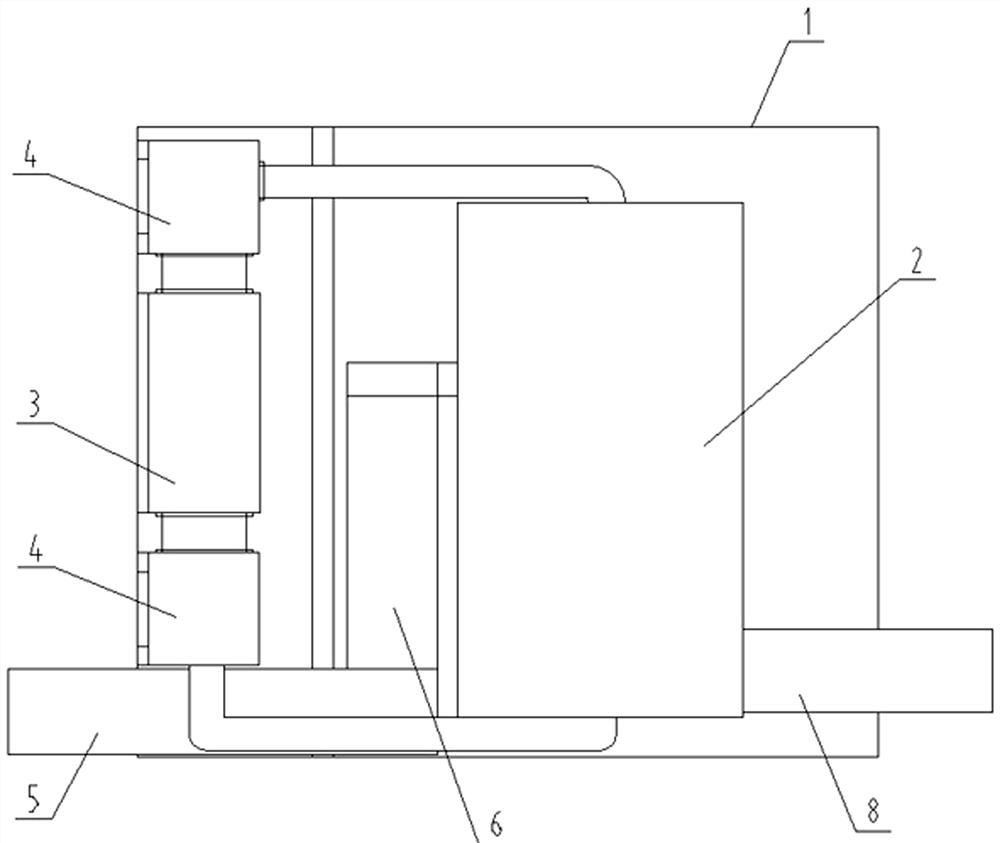

[0028] Such as Figure 1-6 As shown, a drying device includes an independent drying room 1. The drying room 1 adopts a closed drying mode, which is not affected by weather and seasons, and has little impact on the environment of the production workshop.

[0029] A partition 102 is arranged in the drying room 1, which divides the drying room 1 into an equipment room and a drying operation room. Quick-opening airtight doors are installed in the equipment room and the drying operation room to facilitate cleaning and maintenance.

[0030] A closed drying box 2 is arranged in the drying operation room, and a heating and condensing integration box 3 is arranged in the equipment room. 3 are also provided with circulation blower 4.

[0031] Such as Figure 6 As shown, the heating and condensation integration box 3 includes a heating system and a condensation recovery system. The heating system is equipped with a set of SUS304 heaters for each unit. The heaters are made of U-shaped ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com