Multi-stage cavity Raman substrate and preparation method and application thereof

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

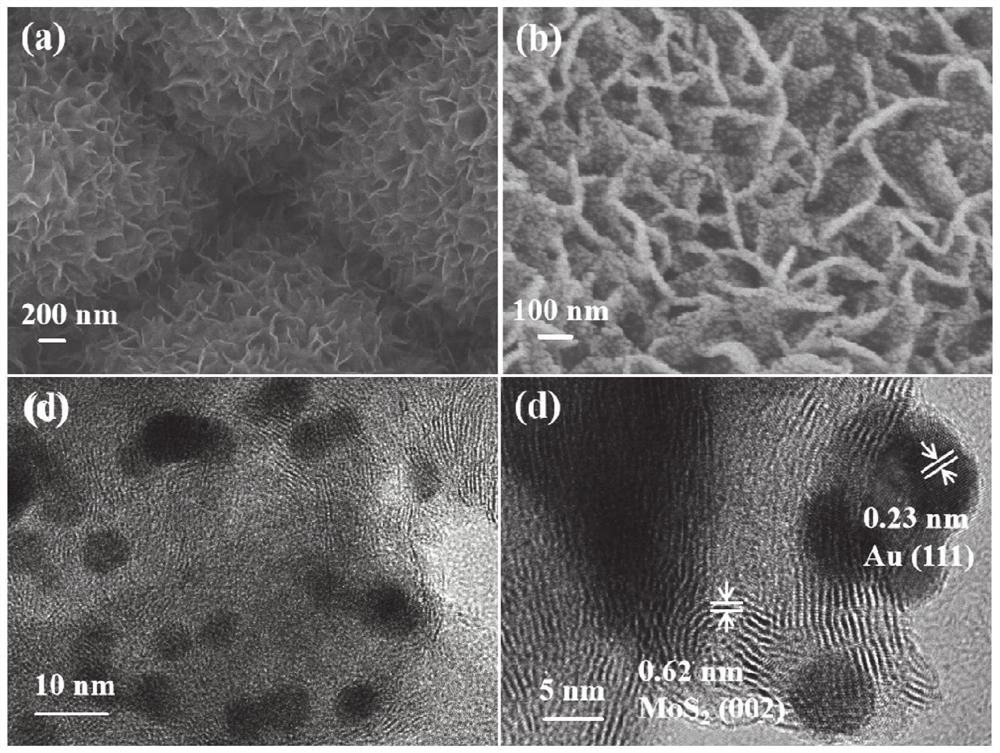

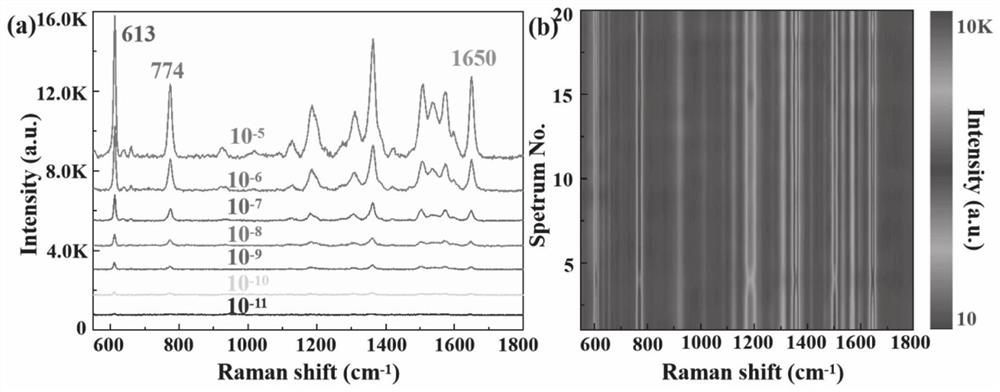

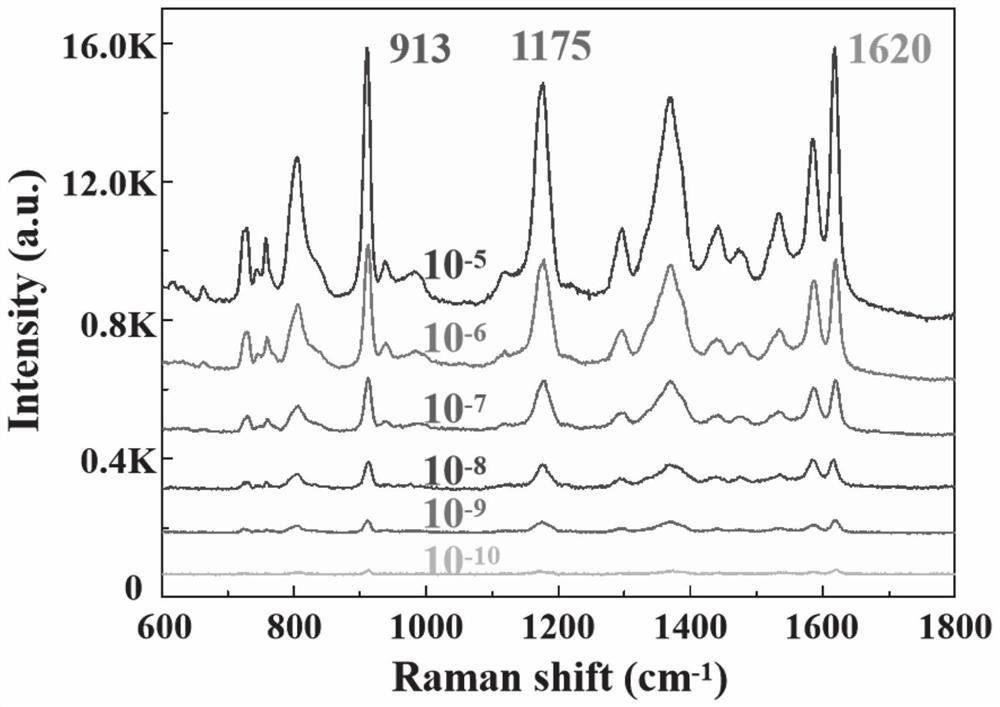

[0058] This embodiment provides a method for preparing a multi-level cavity Raman substrate, including the following preparation steps:

[0059] Preparation of molybdenum disulfide: 1.69g of sodium molybdate and 2.28g of thiourea reagent were dissolved in 30mL of water and alcohol mixed solution at room temperature, wherein the volume ratio of water and alcohol was 1:1. Transfer the mixed solution into an autoclave, put the pyramidal silicon chip into the autoclave, and seal it with a lid. Put the reaction kettle into an oven at a temperature of 180°C for 7 hours.

[0060] Preparation of PSi / MoS2 / Au substrate: the concentration of tetrachloroauric acid in the preparation process of gold nanoparticles was 1 mM, and the reaction time was 3 min. The substrate after the reaction was immersed in deionized water and washed three times to remove the residual tetrachloroauric acid solution to obtain a PSi / MoS2 / Au Raman-enhanced substrate.

Embodiment 2

[0062] This embodiment provides a method for preparing a multi-level cavity Raman substrate, including the following preparation steps:

[0063] Preparation of molybdenum disulfide: 1.69g of sodium molybdate and 2.28g of thiourea reagent were dissolved in 30mL of water and alcohol mixed solution at room temperature, wherein the volume ratio of water and alcohol was 1:1. Transfer the mixed solution into an autoclave, put the pyramidal silicon chip into the autoclave, and seal it with a lid. Put the reaction kettle into an oven at a temperature of 180°C for 7 hours.

[0064] Preparation of PSi / MoS2 / Au substrate: the concentration of tetrachloroauric acid in the preparation process of gold nanoparticles was 1 mM, and the reaction time was 1 min. The substrate after the reaction was immersed in deionized water and washed three times to remove the residual tetrachloroauric acid solution to obtain a PSi / MoS2 / Au Raman-enhanced substrate.

Embodiment 3

[0066] This embodiment provides a method for preparing a multi-level cavity Raman substrate, including the following preparation steps:

[0067] Preparation of molybdenum disulfide: 1.69g of sodium molybdate and 2.28g of thiourea reagent were dissolved in 30mL of water and alcohol mixed solution at room temperature, wherein the volume ratio of water and alcohol was 1:1. Transfer the mixed solution into an autoclave, put the pyramidal silicon chip into the autoclave, and seal it with a lid. Put the reaction kettle into an oven at a temperature of 180°C for 7 hours.

[0068] Preparation of PSi / MoS2 / Au substrate: the concentration of tetrachloroauric acid in the preparation process of gold nanoparticles was 1 mM, and the reaction time was 2 min. The substrate after the reaction was immersed in deionized water and washed three times to remove the residual tetrachloroauric acid solution to obtain a PSi / MoS2 / Au Raman-enhanced substrate.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com