An active clamp no electrolytic capacitor led drive power supply

A technology of LED driving and electrolytic capacitors, which is applied in the direction of electrical components, etc., can solve the problems of large switching stress, switching loss, and high cost, and achieve the effect of realizing no electrolytic capacitors, reducing switching stress, and improving power supply life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] Specific embodiments of the present invention are given below. The specific embodiments are only used to further illustrate the present invention in detail, and do not limit the protection scope of the claims of the present application.

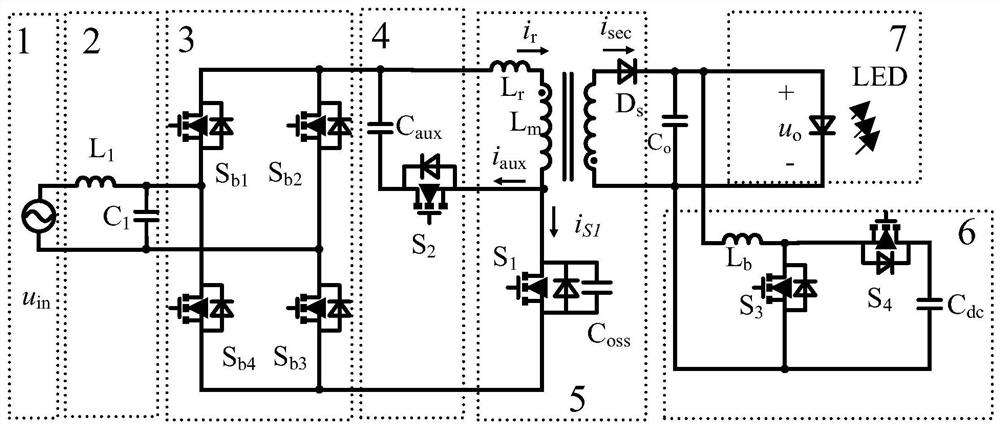

[0030] The present invention provides an active clamping non-electrolytic capacitor LED driving power supply (referred to as driving power supply), which is characterized in that the driving power supply comprises an AC input power supply 1, an input filtering part 2, a rectifying part 3, a clamping circuit 4, a flyback Converter 5, output filter capacitor C o , Parallel absorption circuit 6 and LED load 7;

[0031] The AC input power supply 1 is 220V / 50Hz commercial power.

[0032] The input filtering part 2 adopts LC filtering, and the input filtering inductor L 1 and input filter capacitor C1 The main function of the input filtering part 2 is to filter out the high frequency components of the input.

[0033] The rectifier part 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com