KOH modified bagasse activated carbon adsorption type plant cat litter and preparation method thereof

A technology of activated carbon adsorption and plant cats, which is applied in the field of pet excrement cleaning products, can solve the problems of general adsorption, harmful deodorization, inconvenience, etc., to achieve the purpose of absorbing odors, effectively absorbing odors, and increasing agglomeration performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

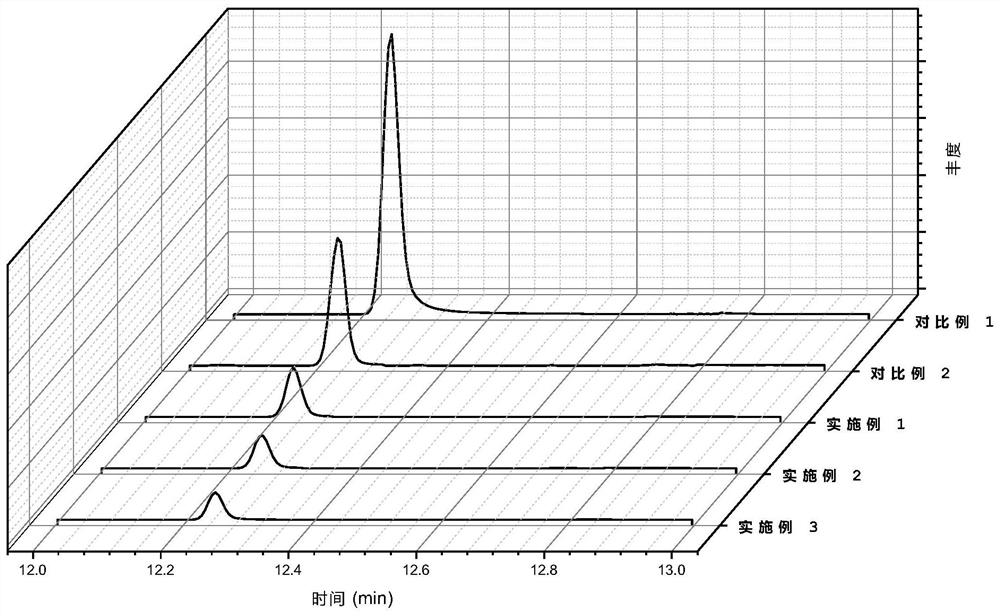

Embodiment 1

[0035] (1) The preparation of KOH modified bagasse activated carbon, the steps are as follows:

[0036] (1) Pulverize the bagasse to a particle size of 80 meshes, then carry out alkaline impregnation to the bagasse, the impregnation time is 20 hours at normal temperature, stir continuously during the impregnation, and dry at 100°C after impregnation; the alkaline impregnation The impregnating liquid is the KOH aqueous solution of 1mol / L, and the mass ratio of described KOH aqueous solution and bagasse is 1:1;

[0037] (2) Place the bagasse after impregnation and drying in a muffle furnace for high-temperature calcination, the calcination temperature is 550° C., and the calcination time is 70 minutes;

[0038] (3) KOH modified bagasse activated carbon was washed with distilled water until neutral, and dried at 90°C.

[0039] (2) The preparation of bagasse modified superabsorbent resin, the steps are as follows:

[0040] S1. The bagasse is crushed to a particle size of 80 mesh...

Embodiment 2

[0056] (1) The preparation of KOH modified bagasse activated carbon, the steps are as follows:

[0057] (1) Pulverize the bagasse to a particle size of 100 meshes, then carry out alkaline impregnation to the bagasse, the impregnation time is 30 hours at room temperature, stirring continuously during the impregnation, and drying at 1110°C after impregnation; the alkaline impregnation The impregnating liquid is the KOH aqueous solution of 4mol / L, and the mass ratio of described KOH aqueous solution and bagasse is 3:1;

[0058] (2) Place the bagasse after impregnation and drying in a muffle furnace for high-temperature calcination, the calcination temperature is 600° C., and the calcination time is 90 minutes;

[0059] (3) KOH modified bagasse activated carbon was washed with distilled water until neutral, and dried at 110°C.

[0060] (2) The preparation of bagasse modified superabsorbent resin, the steps are as follows:

[0061] S1. The bagasse is crushed to a particle size of...

Embodiment 3

[0077] (1) The preparation of KOH modified bagasse activated carbon, the steps are as follows:

[0078] (1) Pulverize the bagasse to a particle size of 90 meshes, then carry out alkaline impregnation to the bagasse, the impregnation time is 24 hours at room temperature, stirring continuously during the impregnation, and drying at 105°C after impregnation; the alkaline impregnation The impregnating liquid is the KOH aqueous solution of 2mol / L, and the mass ratio of described KOH aqueous solution and bagasse is 2:1;

[0079] (2) Place the bagasse after impregnation and drying in a muffle furnace for high-temperature calcination, the calcination temperature is 565° C., and the calcination time is 80 min;

[0080] (3) KOH modified bagasse activated carbon was washed with distilled water until neutral, and dried at 105°C.

[0081] (2) The preparation of bagasse modified superabsorbent resin, the steps are as follows:

[0082] S1. Pulverize the bagasse to a particle size of 90 mes...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com