Chitosan-based antibacterial wound dressing with excellent mechanical properties and antibacterial properties

A wound dressing, chitosan technology, applied in medical science, bandages, etc., can solve problems affecting application effect, complex processing technology and synthesis technology, biocompatibility, etc., achieve good skin adhesion, help On the mechanical properties, the effect of reducing the crosslinking density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] A chitosan-based antibacterial wound dressing with excellent mechanical properties and antibacterial properties, the preparation process of which is as follows:

[0029] (1) Preparation of chitosan heterogeneous solution: Lithium hydroxide, potassium hydroxide, urea, and deionized water were prepared in a certain mass ratio to form a uniform lye, and a certain mass of chitosan powder was weighed and added at room temperature Place in the lye and stir for 2.5h until fully swollen and then freeze at -30°C for 6h, then thaw and stir at 25°C, and form a heterogeneous solution I after standing for 6 hours; wherein the mass fraction of chitosan 5%; the mass ratio of lithium hydroxide, potassium hydroxide, urea, and deionized water in the lye is 5:7:8:81;

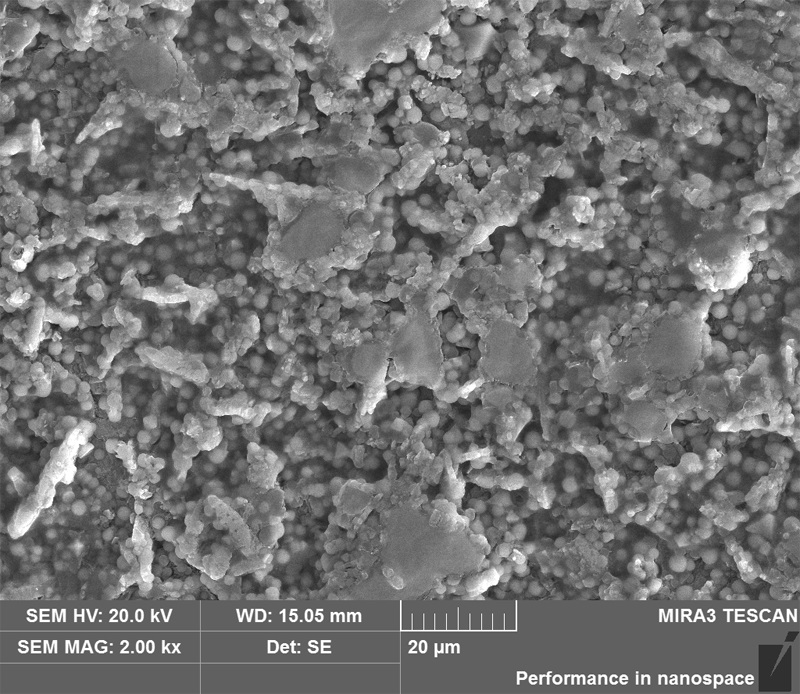

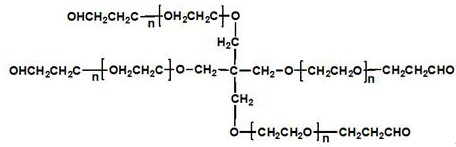

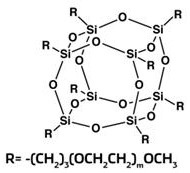

[0030] (2) Preparation of composite solution: Add aldehyde-terminated four-arm polyethylene glycol, amino-terminated four-arm polyethylene glycol, and polyethylene glycol-terminated eight-arm cage silsesquioxane to heteroge...

Embodiment 2

[0040] A chitosan-based antibacterial wound dressing with excellent mechanical properties and antibacterial properties, the preparation process of which is as follows:

[0041] (1) Preparation of chitosan heterogeneous solution: Lithium hydroxide, potassium hydroxide, urea, and deionized water were prepared in a certain mass ratio to form a uniform lye, and a certain mass of chitosan powder was weighed and added at room temperature Place in the lye and stir for 2.4h until fully swollen and then freeze at -30°C for 6.5h, then thaw and stir at 24°C, and form a heterogeneous solution I after standing for 7 hours; wherein the mass of chitosan The fraction is 4.5%; the mass ratio of lithium hydroxide, potassium hydroxide, urea, and deionized water in the lye is 4.5:7.5:8.5:82;

[0042] (2) Preparation of composite solution: Add aldehyde-terminated four-arm polyethylene glycol, amino-terminated four-arm polyethylene glycol, and polyethylene glycol-terminated eight-arm cage silsesqui...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com