Anti-blocking machine tool anti-dust device for precise instrument machining

A precision instrument, dust-proof technology, applied in metal processing machinery parts, metal processing equipment, manufacturing tools, etc., can solve the problems of affecting the dust removal effect, filter clogging, low efficiency, etc., to ensure the filtering effect, stable suction, improve The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

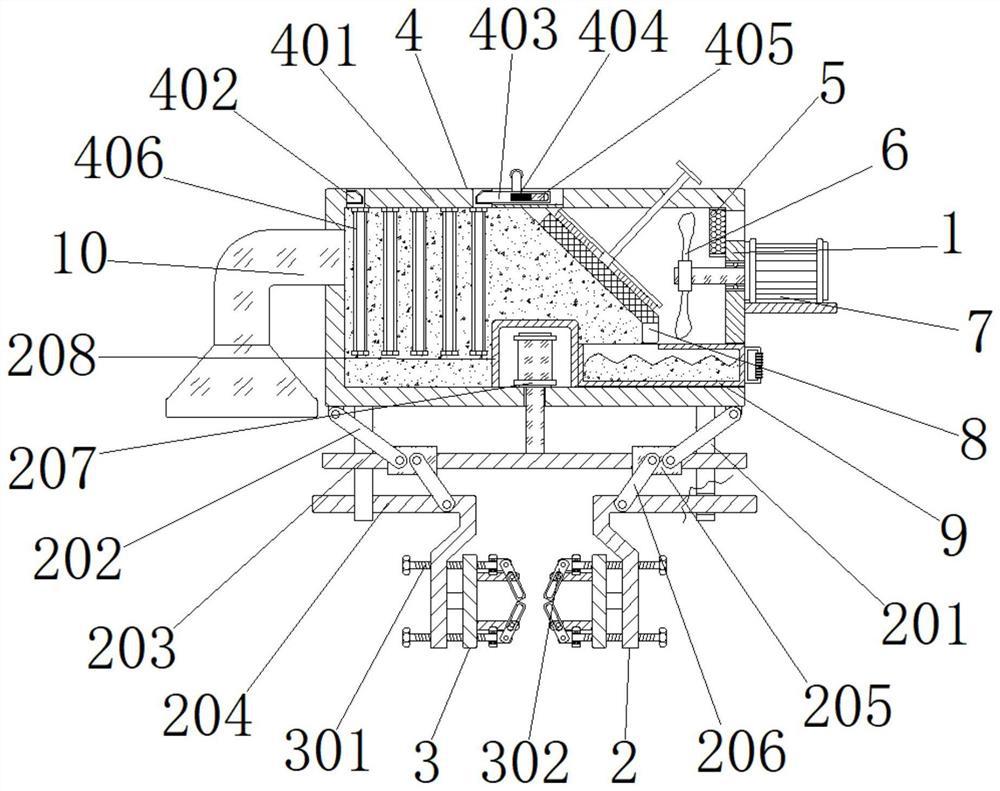

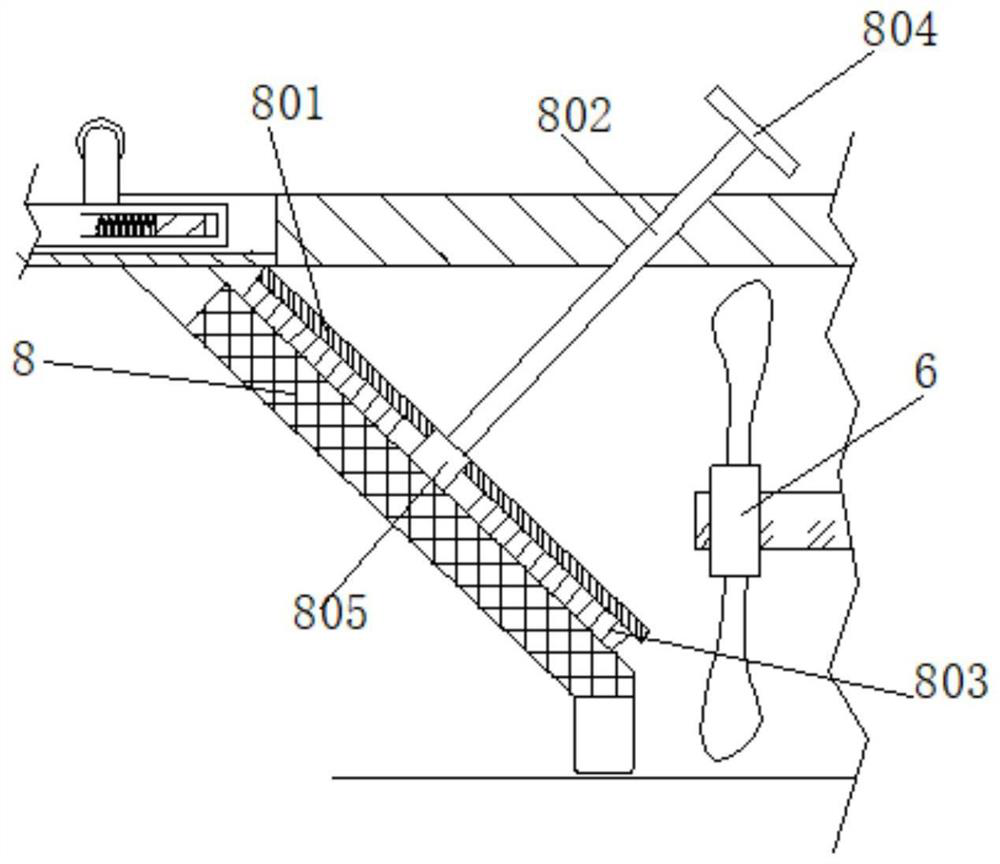

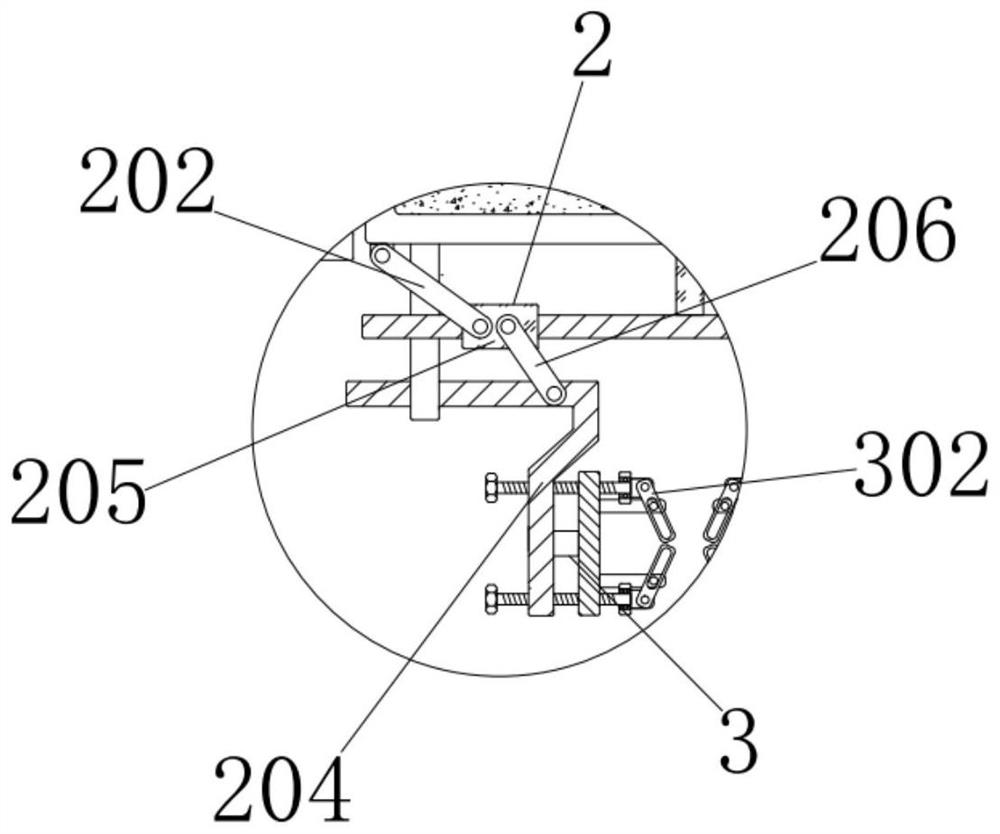

[0040]An anti-clogging type dust-proof device for machine tools for precision instrument processing, including a first box body 1, a motor 7 is fixedly connected to the right end of the first box body 1, the model of the motor 7 is RS550SH-7527, and the output end of the motor 7 is fixedly connected to There are fan blades 6, and the left side of the fan blades 6 is provided with a filter screen 8, the filter screen 8 is a stainless steel 150-200 mesh filter screen, the top of the filter screen 8 is fixedly connected to the top of the inner wall of the first box body 1, and the first box body The left end of 1 is fixedly connected with a dust collecting cover 10, and a clamping device 2 is provided under the first box body 1, and the clamping device 2 includes a vertical plate 201, a first inclined bar 202, a long bar 203, a curved plate 204, and a square 205 , the second slanting rod 206, the cylinder 207 and the square box 208, the tops of the front ends of the two first slan...

Embodiment 2

[0046] As an option, see figure 1 , 3 And 5, anti-clogging type precision instrument processing machine tool dust-proof device, the top right side of the inner wall of the first box 1 is fixed with an activated carbon plate 5, the activated carbon can adsorb all harmful gas molecules in the room, and at the same time has the function of adjusting the catalytic effect , can effectively adsorb various harmful gases formed in the air, such as organic components such as benzene series, formaldehyde, ketones, acids, and planktonic bacteria in the air, and kill mold, Escherichia coli, Staphylococcus aureus, pus, etc. Pathogenic bacteria, inhibit the spread of epidemic pathogens, have comprehensive functions such as detoxification, odor absorption, deodorization, dehumidification, mildew prevention, sterilization, purification, etc. The filtered gas is discharged through the upper opening on the right side of the first box 1 , the top right side of the inner wall of the first box bo...

Embodiment 3

[0049] As an option, see figure 1 , 6 And 7, the anti-clogging type precision instrument processing machine tool dustproof device, the left side of the inner cavity of the first box body 1 is provided with a filter device 4, and the filter device 4 includes a horizontal plate 401, a protrusion 402, a cross bar 403, a spring 404, The long block 405 and the cloth bag 406, the left end of the projection 402 is fixedly connected with the left side of the inner wall of the first box body 1, the outer wall of the projection 402 is in clearance fit with the left groove of the horizontal plate 401, and the right groove of the horizontal plate 401 There is a crossbar 403 in the gap, and a handle is fixedly connected to the top of the crossbar 403. This design is more convenient to slide the crossbar 403 to the right. The outer wall of the crossbar 403 is in clearance with the inner wall of the groove on the left side of the top of the first box body 1. A spring 404 is affixed to the l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com