Pre-reduced graphene oxide film and preparation method thereof, and graphene heat conduction film and preparation method thereof

A graphene film, graphene technology, applied in graphene, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of increasing the production cost of graphene thermal conductive film, low reduction efficiency of graphene oxide film, etc., to achieve pre-reduction The process is convenient and quick, the choice of reducing agent is wide, and the controllability is strong.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0053] As the first embodiment of the present invention, the present invention shows a method for preparing a pre-reduced graphene oxide film, including: adding a chemical reducing agent to the graphene oxide slurry, stirring and dispersing, coating, drying, and obtaining a pre-reduced graphene oxide film. Reduced graphene oxide film; the chemical reducing agent is 0.005%-0.15% of the graphene oxide content, for example: 0.005%, 0.006%, 0.007%, 0.008%, 0.009%, 0.01%, 0.015%, 0.02%, 0.025%, 0.03%, 0.035%, 0.04%, 0.045%, 0.05%, 0.055%, 0.06%, 0.065%, 0.07%, 0.075%, 0.08%, 0.085%, 0.09%, 0.095%, 0.1%, 0.11% , 0.12%, 0.13%, 0.14%, 0.141%, 0.142%, 0.145%, 0.148%, 0.149%, 0.15%, etc.

[0054] In order to improve the thermal reduction efficiency of graphene heat conduction film prepared from graphene oxide, the pre-reduction treatment of graphene oxide was introduced in the process of preparing graphene heat conduction film, from the original "dispersion-coating-drying-reduction" to ...

Embodiment 1A

[0074] This example shows a preparation process of a pre-reduced graphene oxide film.

[0075] step 1):

[0076] Configure 10 kg of graphene oxide aqueous slurry with a solid content of 2.5%, and measure its viscosity to be 20 Pa s; add 50 mL of solution to dissolve 0.375 g of the chemical reducing agent solution of sodium citrate in the graphene oxide aqueous slurry, and stir evenly After that, its viscosity was measured to be 19.7Pa·s.

[0077] Step 2):

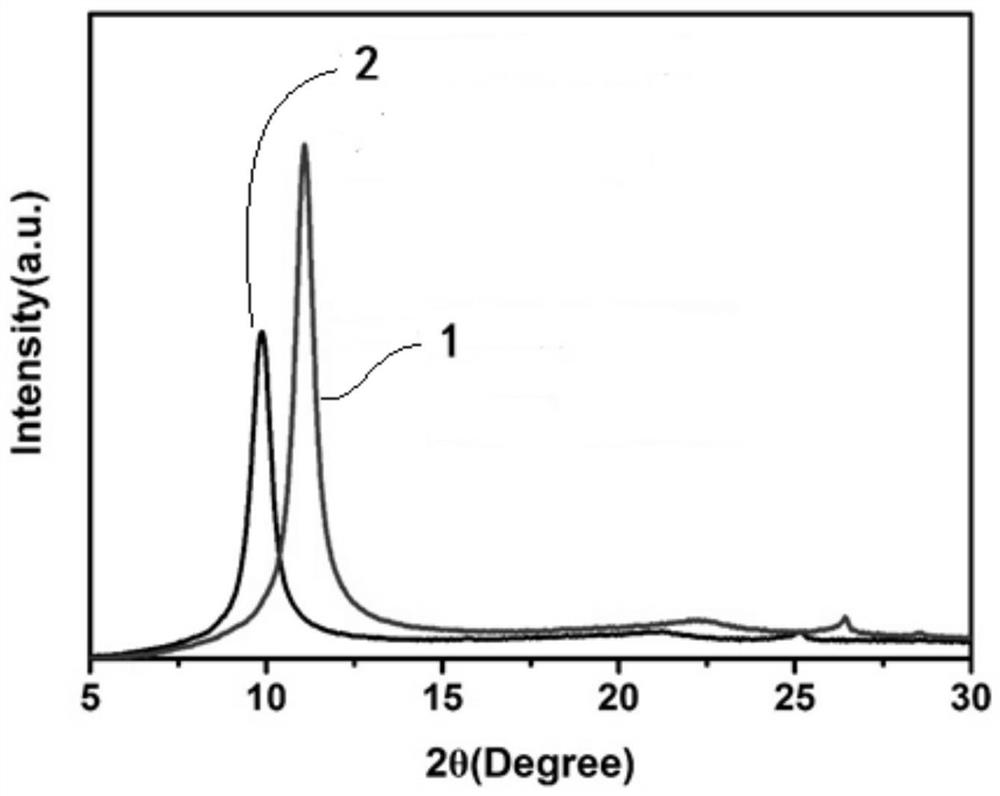

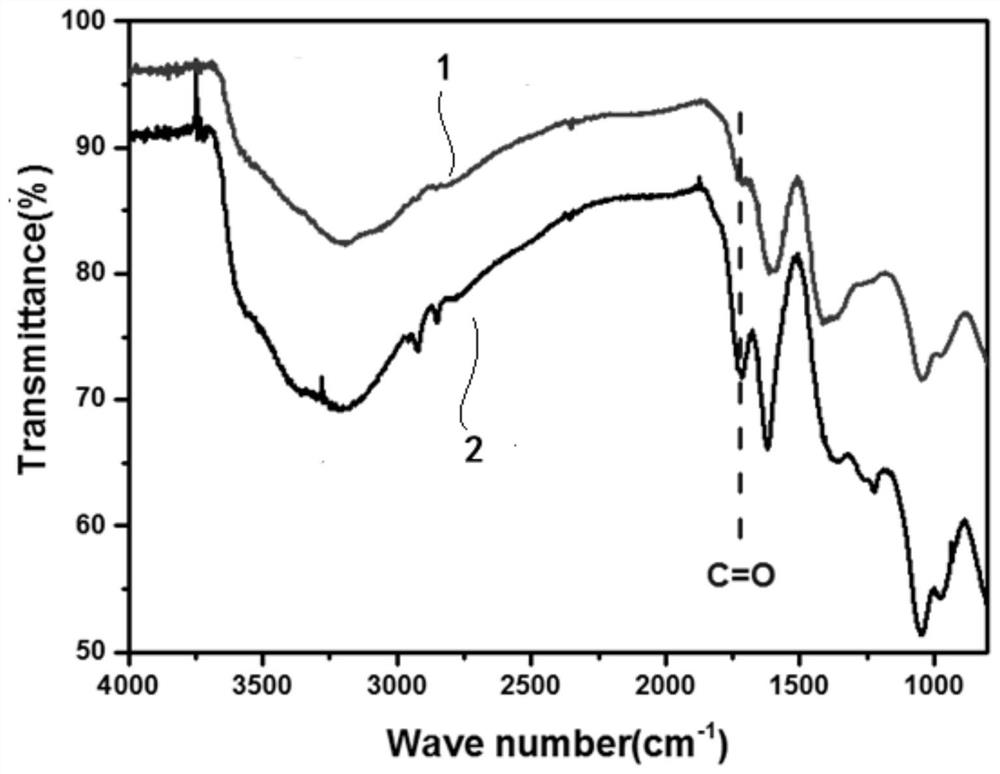

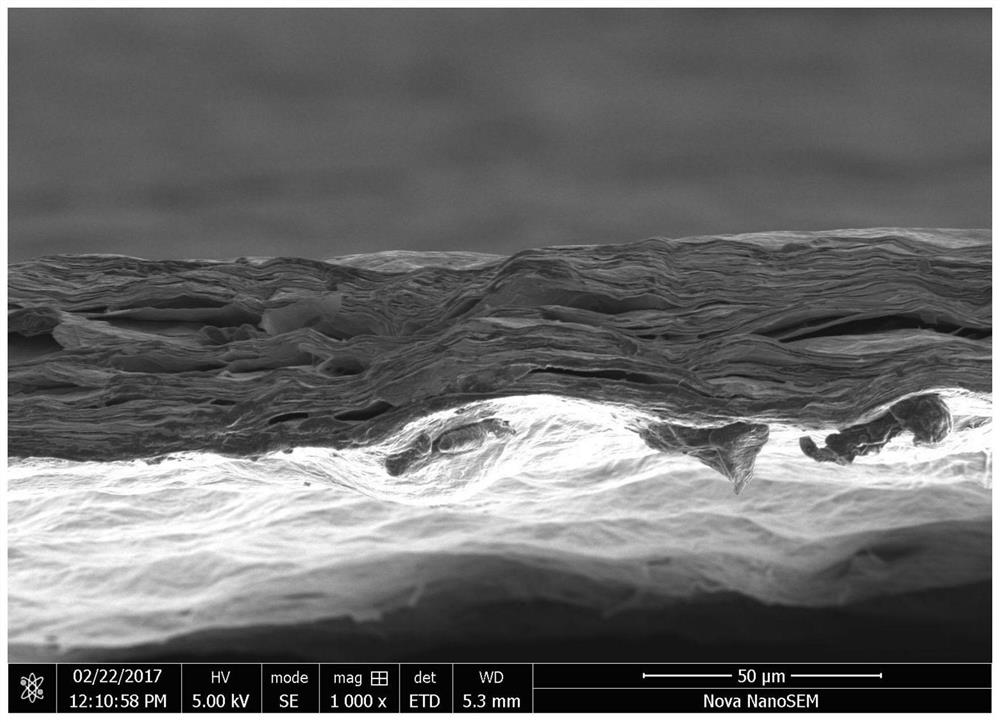

[0078] The solution prepared in step 1) is coated with a film, and dried at 40-120° C. for 20-180 min to obtain a pre-reduced graphene oxide film, such as image 3 As shown, the pre-reduced graphene oxide film is well assembled, and the addition of a small amount of chemical reducing agent will not affect the assembly of the graphene oxide film.

Embodiment 1B

[0080] This embodiment shows a preparation process of a graphene heat-conducting film, and the graphene heat-conducting film is prepared by using the pre-reduced graphene oxide film prepared in Example 1A.

[0081] The pre-reduced graphene oxide film prepared in Example 1A was subjected to thermal reduction at a reduction temperature of 2000-3000° C., and heat preservation treatment was carried out for 2 hours to obtain a graphene heat-conducting film. The thermal conductivity of the graphene thermal film is 1158W / m·K.

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com