Synthesis method of rubber modified solid thermosetting phenolic resin

A technology of rubber modification and phenolic resin, applied in the field of phenolic resin, can solve the problems of shortened polymerization speed of phenolic resin, poor compatibility and stability of phenolic resin and rubber, no improvement in heat resistance of phenolic resin, etc. The effect of good heat resistance and flexibility, good compatibility and stability, and excellent performance reliability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

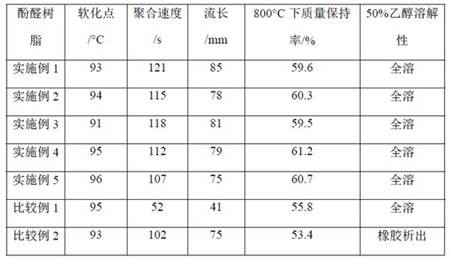

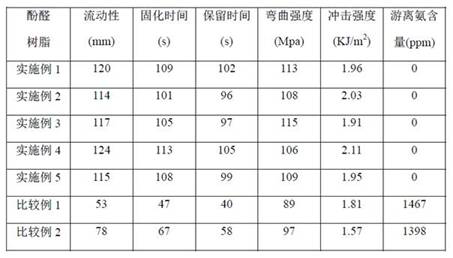

Examples

Embodiment 1

[0043] Put 1000kg of preheated and melted phenol into the high-level metering tank with a special pump, and then add 50kg of styrene-butadiene rubber with a number average molecular weight of 45,000 and 5kg of p-toluenesulfonic acid into the reactor, and heat it up to 160°C for heat preservation. After reacting for 3 hours and the temperature dropped to 80°C, 1.25 kg of sodium hydroxide was added to adjust the pH to 3-4. Then add 1500kg of formaldehyde aqueous solution with a mass fraction of 37%, 0.5kg of catalyst barium chloride, raise the temperature to 100°C, and keep it under reflux for 6 hours. After the heat preservation is over, dehydrate at normal pressure to 120°C, vacuum dehydrate to 130°C (vacuum degree is less than 0.095Mpa), and when the polymerization speed of the phenolic resin is detected to be 105-135s, stop the reaction, release the product, and obtain a light yellow solid 1030kg after cooling .

Embodiment 2

[0045] Put 1000kg of preheated and melted phenol into the high-level metering tank with a special pump, and measure it into the reactor, then add 100kg of nitrile rubber with a number average molecular weight of 4000, and 1kg of concentrated sulfuric acid into the reactor, heat up to 80°C and keep it warm for 5 hour, after the insulation finishes, add sodium hydroxide 0.8kg, adjust pH to 3-4. Then add 1350kg of formaldehyde solution with a mass fraction of 37%, 10kg of catalyst calcium acetate, raise the temperature to 100°C, and keep it under reflux for 3 hours. After the heat preservation is over, the dehydration temperature under normal pressure reaches 120°C, vacuum dehydration reaches 130°C (vacuum degree is less than 0.095Mpa), and when the polymerization speed of the phenolic resin is detected to be 105-135s, the reaction is stopped, the product is released, and 1270kg of a light yellow solid is obtained after cooling.

Embodiment 3

[0047] Put 1000kg of preheated and molten phenol into the high-level metering tank with a special pump, and then add 200kg of butyl rubber with a number-average molecular weight of 13,000 and 15kg of p-toluenesulfonic acid into the reactor, and heat it up to 110°C for heat preservation. React for 4 hours. After the heat preservation is completed, add 2.5 kg of sodium hydroxide to adjust the pH to 3-4. Then add 200kg of paraformaldehyde, 400kg of formaldehyde solution with a mass fraction of 37%, 50kg of catalyst zinc acetate, raise the temperature to 100°C, and keep it under reflux for 2 hours. After the heat preservation is over, dehydrate at normal pressure to 120°C, and vacuum dehydrate to 130°C (vacuum degree less than 0.095Mpa). When the polymerization speed of the phenolic resin is detected to be 105-135s, the reaction is stopped, and the product is released. After cooling, 1380Kg of a light yellow solid is obtained. .

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com