High-brightness powder coating and preparation method thereof

A powder coating and bright technology, used in powder coatings, polyester coatings, coatings, etc., can solve the problems that powder coatings are difficult to meet requirements, and the brightness of coatings is not high.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

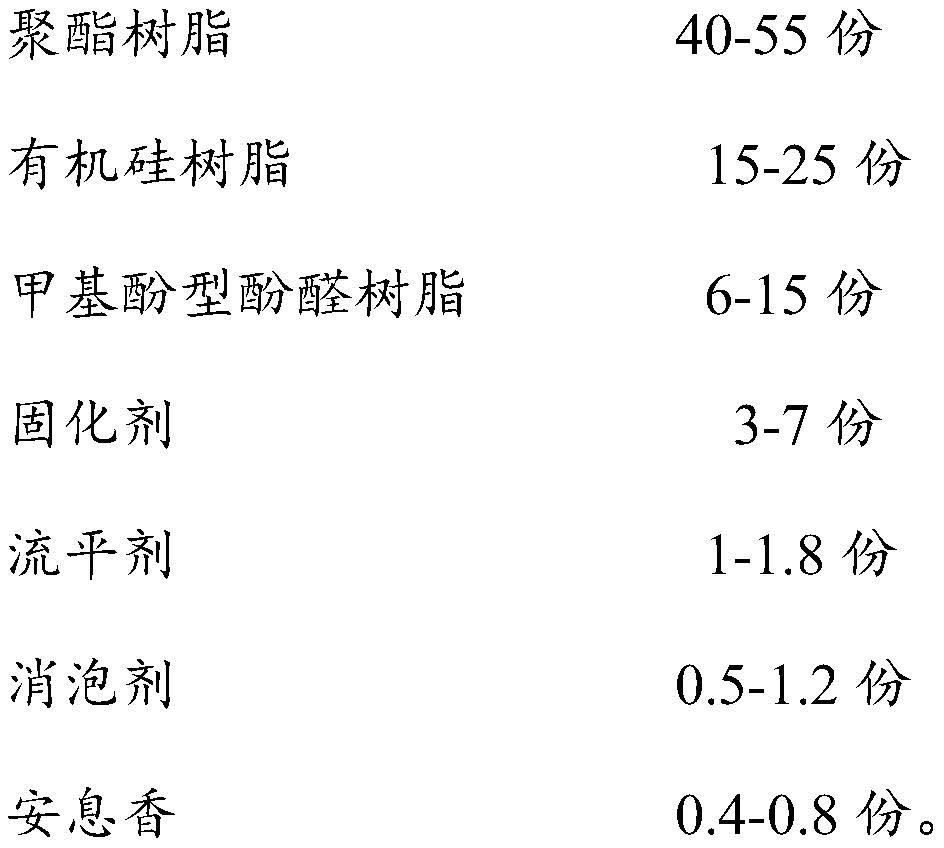

[0031] A preparation method of high gloss powder coating, the method is:

[0032] Mixing: Add polyester resin, silicone resin, methylphenol phenolic resin, curing agent, leveling agent, defoamer and benzoin into the mixer at a temperature of 40-50°C and a speed of 250-450r / min, mixed for 5-10min to obtain the mixture;

[0033] Extrusion: Put the compound into the twin-screw extruder, the cavity temperature is 90-105°C, the head temperature is 100-110°C, the screw speed is 150-200r / min, melt extrusion to obtain the extrudate ;

[0034] Tabletting: Add the extrudate to a tablet press while it is hot for tableting, and then cool it down naturally to obtain a tablet;

[0035] Pulverization: put the compressed tablet into a pulverizer, the single pulverization time is 15-30s, the pulverization times are 3-5 times, and pass through a 200-300 mesh sieve to obtain a powder coating.

Embodiment 1

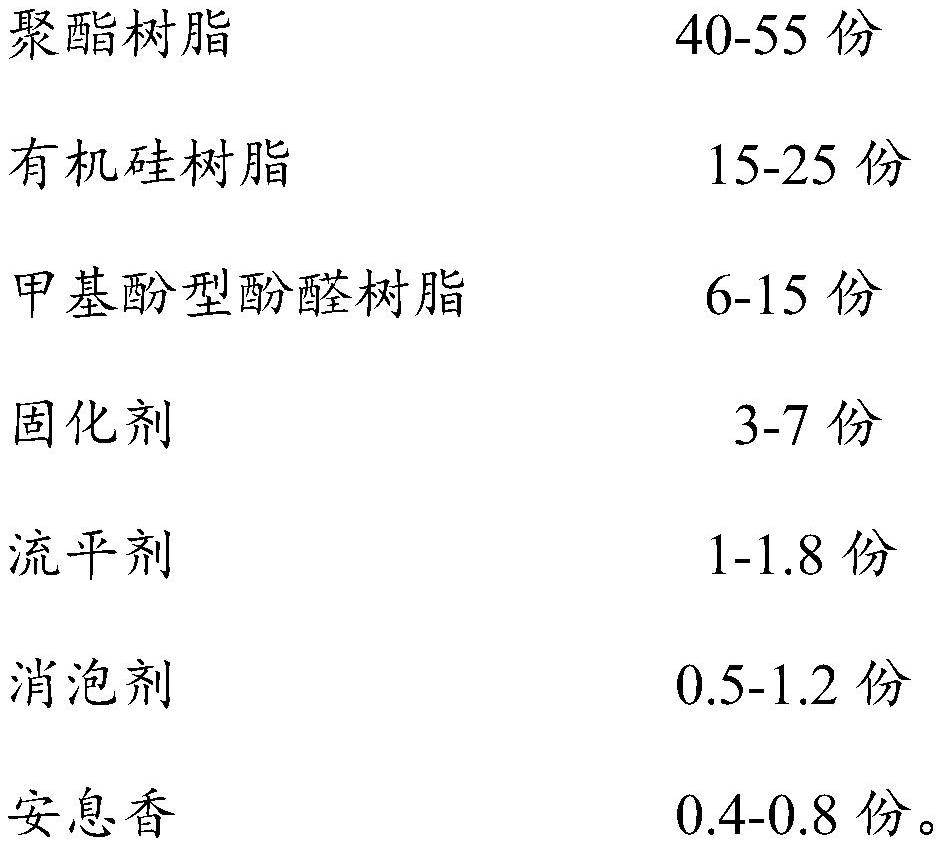

[0037] A kind of high gloss powder coating, raw material comprises by weight component:

[0038]

[0039] Wherein, the curing agent is β-hydroxyalkylamide; the leveling agent is polydimethylsiloxane; the brightener is an acrylic ester copolymer; the defoaming agent is emulsified silicone oil.

[0040] A preparation method of high gloss powder coating, the method is:

[0041] Mixing: Add polyester resin, silicone resin, methylphenol phenolic resin, curing agent, leveling agent, defoamer and benzoin into the mixer at a temperature of 40°C and a speed of 450r / min, and mix 5min, to obtain the mixture;

[0042] Extrusion: Add the mixed material to the twin-screw extruder, the cavity temperature is 90°C, the head temperature is 100°C, the screw speed is 200r / min, melt extrusion to obtain the extrudate;

[0043] Tabletting: Add the extrudate to a tablet press while it is hot for tableting, and then cool it down naturally to obtain a tablet;

[0044] Pulverization: put the compr...

Embodiment 2

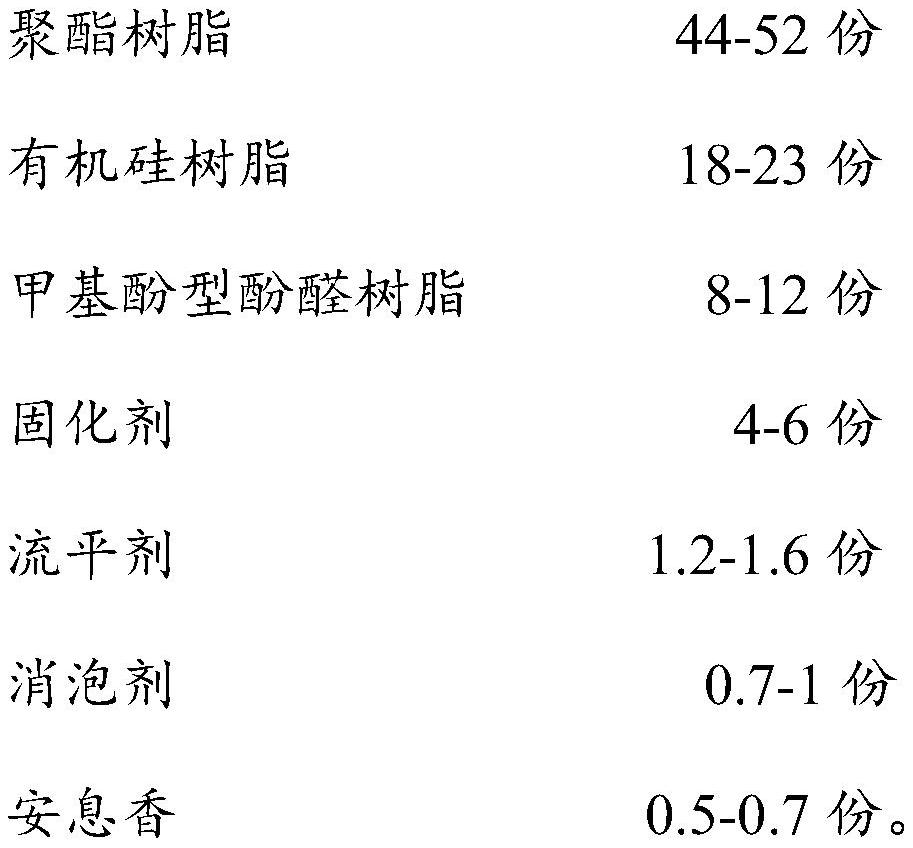

[0046] A kind of high gloss powder coating, raw material comprises by weight component:

[0047]

[0048] Wherein, the curing agent is phenolic resin; the leveling agent is alkyl modified organosiloxane; the brightener is methyl methacrylate homopolymer; the defoaming agent is polyoxyethylene polyoxypropylene pentaerythritol ether.

[0049] A preparation method of high gloss powder coating, the method is:

[0050] Mixing: Add polyester resin, silicone resin, methylphenol phenolic resin, curing agent, leveling agent, defoamer and benzoin into the mixer at a temperature of 42°C and a speed of 420r / min, and mix 7min, obtain mixture;

[0051] Extrusion: Add the mixed materials into the twin-screw extruder, the cavity temperature is 102°C, the head temperature is 108°C, the screw speed is 160r / min, melt extrusion to obtain the extrudate;

[0052] Tabletting: Add the extrudate to a tablet press while it is hot for tableting, and then cool it down naturally to obtain a tablet; ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com