Preparation method of bright and anticorrosive aluminum profiles

An aluminum profile and bright technology, applied in the direction of metal material coating process, etc., can solve the problem that the performance of aluminum alloy profiles needs to be improved, and achieve the effects of small loss, good performance and good dispersion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

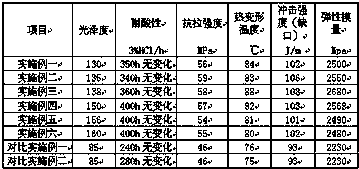

Examples

Embodiment 1

[0030] Aluminum profile preparation: Melt aluminum ingots into liquid aluminum, add zirconium-wrapped titanium dioxide and zirconium-wrapped silica mixed powders at a mass ratio of 1:2, the mixed powders account for 0.5% of the mass of the aluminum ingots, and then melt at the melting temperature Keep it for 3 hours; then pour it into a mold above 600°C under a pressure of 1.1MPa. After pouring into the mold, cool it to 350°C at a rate of 60-80°C per hour, then keep it warm for 2 hours, and then cool it at a rate of 30°C per hour to Insulate at 80°C for 1 hour; then cool at room temperature and release the aluminum profile.

[0031] Preparation of bright and anti-corrosion aluminum profiles:

[0032] Preparation of bright anticorrosion liquid: prepare 40 parts of sodium fluoride, 60 parts of ammonium bifluoride, 20 parts of potassium permanganate, 50 parts of potassium chromate, 25 parts of zinc phosphate, 18 parts of sodium nitrate, 12 parts of praseodymium chloride, and 16 ...

Embodiment 2

[0038] Aluminum profile preparation: Melt aluminum ingots into liquid aluminum, add zirconium-wrapped titanium dioxide and zirconium-wrapped silica mixed powders at a mass ratio of 1:3, the mixed powders account for 1.2% of the mass of the aluminum ingots, and then melt at the melting temperature Keep it for 5 hours; then pour it into a mold above 600°C under a pressure of 1.5MPa, cool it to 450°C at a rate of 80°C per hour after pouring into the mold, keep it for 3 hours, and then cool it to 100°C at a rate of 40°C per hour Keep warm for 2 hours; then cool at room temperature and demould the aluminum profile.

[0039] Preparation of bright and anti-corrosion aluminum profiles:

[0040] Preparation of bright anticorrosion liquid: prepare 40 parts of sodium fluoride, 60 parts of ammonium bifluoride, 20 parts of potassium permanganate, 40-50 parts of potassium chromate, 25 parts of zinc phosphate, 18 parts of sodium nitrate, and 12 parts of praseodymium chloride by weight , 16 ...

Embodiment 3

[0046] Aluminum profile preparation: Melt aluminum ingots into liquid aluminum, add zirconium-wrapped titanium dioxide and zirconium-wrapped silica mixed powders at a mass ratio of 1:2-3, the mixed powders account for 0.9% of the mass of the aluminum ingots, and then melt Keep at the temperature for 4 hours; then pour it into a mold above 600°C under a pressure of 1.3MPa, pour it into the mold and cool it to 390°C at a rate of 70°C per hour, then keep it for 2.5 hours, and then cool it at a rate of 38°C per hour to Insulate at 90°C for 1.5 hours; then cool at room temperature and release the aluminum profile.

[0047] Preparation of bright and anti-corrosion aluminum profiles:

[0048] Preparation of bright anticorrosion liquid: prepare 26 parts of sodium fluoride, 40 parts of ammonium bifluoride, 18 parts of potassium permanganate, 46 parts of potassium chromate, 19 parts of zinc phosphate, 12 parts of sodium nitrate, 9 parts of praseodymium chloride, and 13 parts of diamine...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com