Hydroentangled nonwoven fabric mask pack sheet having layered structure and method for manufacturing same

A layered structure and manufacturing method technology, applied in textiles and papermaking, non-woven fabrics, pharmaceutical formulations, etc., can solve problems such as tearing, and achieve excellent skin-adhesive effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

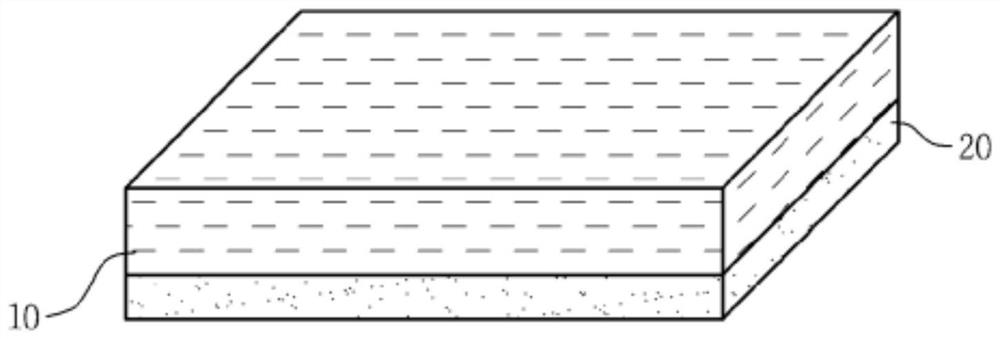

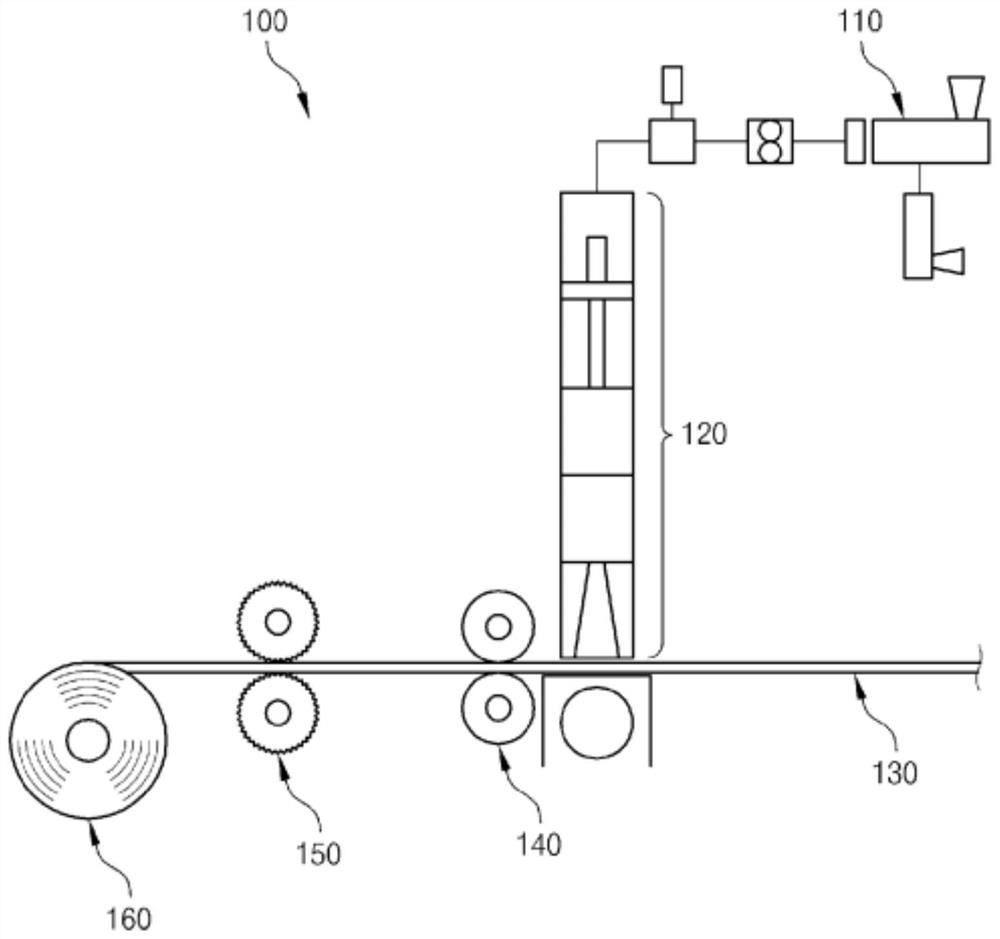

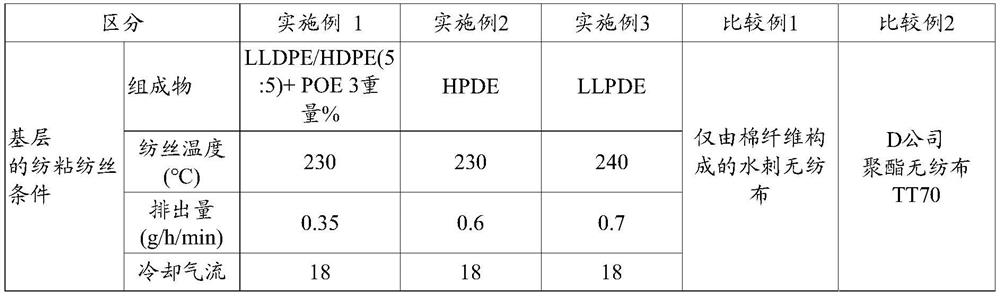

[0055] in having as figure 1 In the general spunbond spinning equipment 100 of the structure shown, LLDPE / HDPE resin (5:5 weight ratio) having a melting temperature (Tm) of 182° C. and an intrinsic viscosity (IV) of 1.53 is charged into the raw material inlet 110 , Furthermore, 3% of polyolefin elastomer (POE) was added, and spunbond spinning was performed at a spinning extruder temperature of 230°C.

[0056] The filaments spun by a plurality of spinnerets were laminated on the conveyor belt 130 to produce 50 g / m 2 A base layer 10 of long fiber elastic nonwoven fabric by weight.

[0057] After carding cotton fibers on one surface of the base layer 10 thus produced, and laminating 1.0 mm in a web, 5 kgf / cm was applied in the hydroentangling process 2 The hydroentangling pressure and drying at 110° C. for 30 minutes, thereby manufacturing a nonwoven fabric mask sheet in which the outer layer 20 is hydroentangled on one surface of the base layer 10 . The weight ratio of the b...

Embodiment 2、3

[0059] Under the conditions shown in Table 1, in the same manner as in Example 1, a mask with an interlayer structure in which the base layer 10 and the outer layer 20 were laminated was produced.

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| elongation at break | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com