Preparation method of hawthorn leaf aqueous extract

A technology of hawthorn extract and hawthorn leaf, which is applied in the field of preparation of hawthorn leaf water extract, can solve the problem of losing the effective components of hawthorn leaf, achieve the effect of improving the purification rate, promoting dissolution, and improving the purification rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

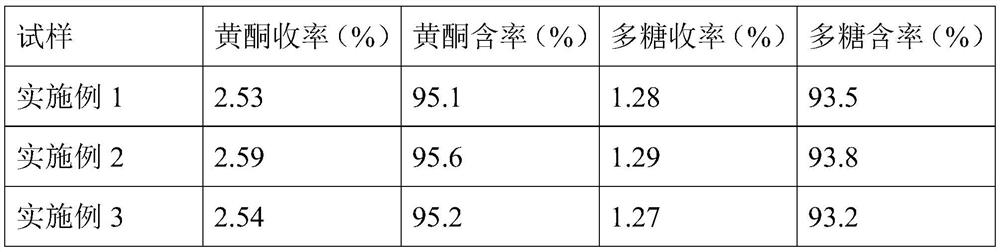

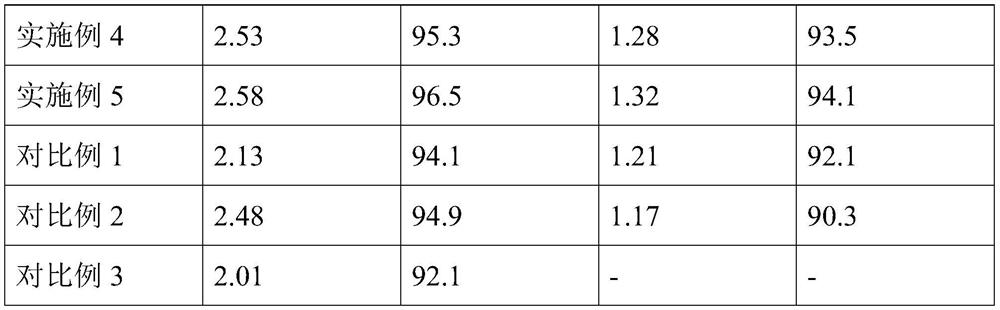

Examples

Embodiment 1

[0025] 100g hawthorn leaves are pulverized, water is added, and tetrabutyl phosphate alanine ionic liquid is added to obtain a mixed material liquid, the amount of water added is 7 times of the mass of hawthorn leaves; the addition of tetrabutyl phosphate alanine ionic liquid The amount is 0.7 times of the mass of hawthorn leaves; air is blown into the mixture liquid, and the air velocity is 30ml / min; the mixture liquid is heated by microwave for 60s in an ultrasonic environment, and heated once every 10s; ultrasonic power is 200W, and ultrasonic temperature is 40 °C; first separate the foam on the mixed material liquid, then centrifuge the mixed material liquid after removing the foam, take the supernatant and concentrate it to obtain a primary extract;

[0026] Add the primary extract to the propanol-ammonium sulfate dual-phase system, the mass fraction of propanol in the propanol-ammonium sulfate dual-phase system is 30%, and the mass fraction of ammonium sulfate is 10%;

...

Embodiment 2

[0032] 100g hawthorn leaves are pulverized, water is added, and tetrabutyl phosphate alanine ionic liquid is added to obtain a mixed material liquid, the amount of water added is 8 times of the mass of hawthorn leaves; the addition of tetrabutyl phosphate alanine ionic liquid The amount is 0.9 times of the quality of hawthorn leaves; air is blown into the mixture liquid, and the airflow speed is 120ml / min; the mixture liquid is heated by microwave for 80s in an ultrasonic environment, and heated once every 20s; the ultrasonic power is 300W, and the ultrasonic temperature is 50 °C; first separate the foam on the mixed material liquid, then centrifuge the mixed material liquid after removing the foam, take the supernatant and concentrate it to obtain a primary extract;

[0033] Add the primary extract to the propanol-ammonium sulfate two-phase system, the mass fraction of propanol in the propanol-ammonium sulfate two-phase system is 40%, and the mass fraction of ammonium sulfate ...

Embodiment 3

[0039] 100g hawthorn leaves are pulverized, water is added, and tetrabutyl phosphate alanine ionic liquid is added to obtain a mixed material liquid, the amount of water added is 10 times of the mass of hawthorn leaves; the addition of tetrabutyl phosphate alanine ionic liquid The amount is 1.5 times of the mass of hawthorn leaves; air is blown into the mixture liquid, and the air velocity is 200ml / min; the mixture liquid is heated by microwave for 100s in an ultrasonic environment, and heated once every 25s; the ultrasonic power is 400W, and the ultrasonic temperature is 80 °C; first separate the foam on the mixed material liquid, then centrifuge the mixed material liquid after removing the foam, take the supernatant and concentrate it to obtain a primary extract;

[0040] Add the primary extract to the propanol-ammonium sulfate dual-phase system, the mass fraction of propanol in the propanol-ammonium sulfate dual-phase system is 60%, and the mass fraction of ammonium sulfate ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com