High-temperature-resistant release film and preparation method thereof

A release film, high temperature resistant technology, used in chemical instruments and methods, other household appliances, electronic equipment, etc., can solve the problems of easy wrinkling during the pressing process, unfavorable recycling of fluorine-containing materials and environmental protection, and achieve low thermal shrinkage. rate, high resistance glue, high release effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0021] The preparation method of the high temperature resistant release film provided by the invention comprises the following steps:

[0022] Put 100% PMP into A twin-screw extruder, and put into B twin-screw extruder the mixture of COC, PP, and POE-g-MAH according to the ratio, and perform melt plasticization and melt filtration respectively. T-shaped die head, cooling film forming, tempering, winding, slitting and packaging.

[0023] Further, the temperature of each zone of the A twin-screw extruder is 230-270°C. The filter mesh has a pore size of 10-15 μm. The temperature in each zone of the B twin-screw extruder is 220-260°C. The filter mesh has a pore size of 10-15 μm. Die temperature was 260-280°C. Casting speed is 30-50m / min. The tempering roll temperature is 70-120°C.

[0024] The structural diagram of the release film is shown in figure 1 , A is the release layer, and B is the resist layer.

[0025] The test method of the performance of reflective polyester f...

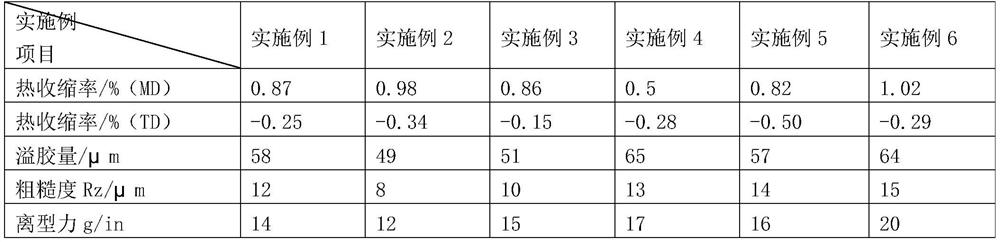

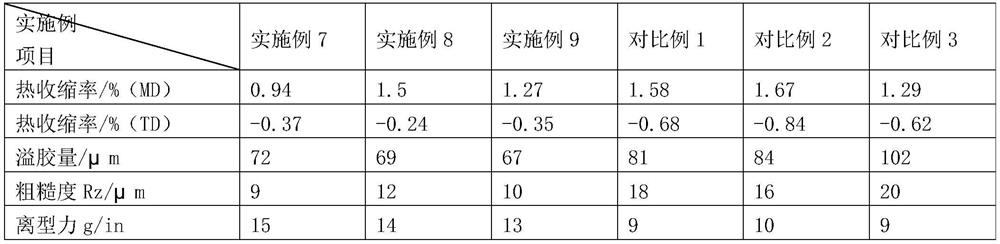

Embodiment 1

[0032] The proportion of release layer A is 100% RT18. The proportion of layer B of the adhesive barrier layer is 50% 6015, 45% PP (MFR = 1g / 10min), 5% POE-g-MAH. The total thickness of the release film is 110 μm, the thickness of layer A is 40 μm, and the thickness of layer B is 70 μm. The relevant properties are shown in Table 1.

Embodiment 2

[0034] The proportion of release layer A is 100% RT18. The proportion of layer B of the adhesive barrier layer is 55% 6015, 50% PP (MFR=2g / 10min), 5% POE-g-MAH. The total thickness of the release film is 120 μm, the thickness of layer A is 40 μm, and the thickness of layer B is 80 μm. The relevant properties are shown in Table 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com