One-component easy-release type hyperbranched-structural UV resin capable of inkjet printing and preparation method of resin

An inkjet printing, one-component technology, used in inks, household appliances, applications, etc., can solve the problems of difficult adhesion of inks, incompatibility of resin systems, poor compatibility, etc., to achieve high release properties and easy inking. properties, high release and slip properties, low surface friction coefficient

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0037] (1) Preparation of difunctional carboxyl-terminated UV active monomers:

[0038] (A) Weigh 116g of hydroxyethyl acrylate, 98g of maleic anhydride and 0.107g of triphenylphosphine into the reaction kettle, stir, and slowly heat up to 90°C for 30 minutes;

[0039] (B) heat preservation reaction for 5 hours to prepare a difunctional carboxyl-terminated UV active monomer.

[0040] (2) Preparation of hyperbranched polysiloxane active body:

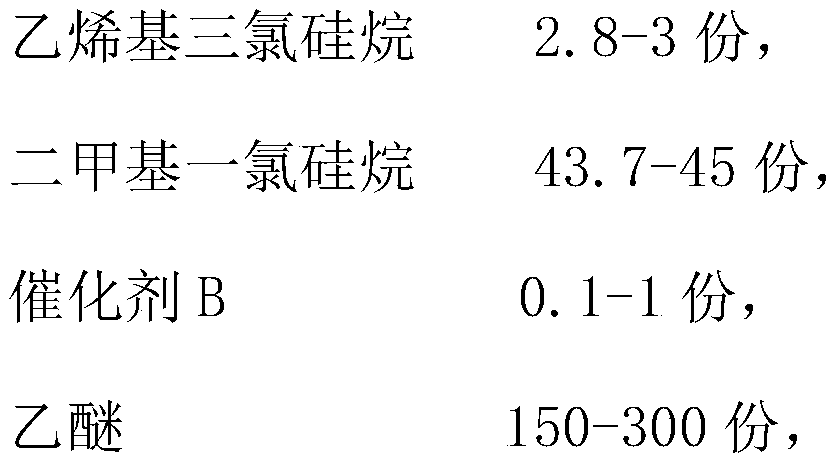

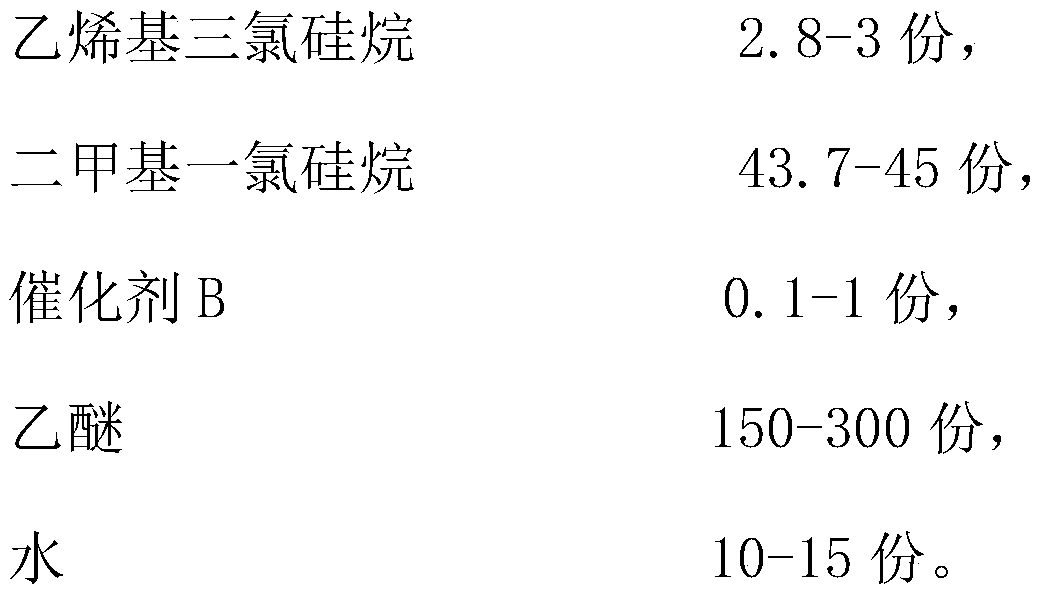

[0041] (A) Add 2.8g of vinyltrichlorosilane, 45g of dimethylmonochlorosilane, 150g of diethyl ether, 10g of water, and 0.1g of chloroplatinic acid into the reaction kettle, and stir for 6 hours at 30°C;

[0042] (B) Heating up to 100°C, vacuuming under reduced pressure to remove water and ether as a solvent to prepare a hyperbranched polysiloxane active body.

[0043] (3) Preparation of carboxyl-terminated hyperbranched polysiloxane modified body:

[0044] (A) 90 g of hyperbranched polysiloxane active body and 0.1 g of chloroplatinic ...

Embodiment 2

[0049] (1) Preparation of difunctional carboxyl-terminated UV active monomers:

[0050] (A) Weigh 116g of hydroxyethyl acrylate, 166g of methyltetrahydrophthalic anhydride and 2.82g of triethylamine into the reaction kettle, stir, and slowly heat up to 93°C in 40 minutes;

[0051] (B) heat preservation reaction for 3 hours to prepare a difunctional carboxyl-terminated UV active monomer.

[0052] (2) Preparation of hyperbranched polysiloxane active body:

[0053] (A) Add 3 g of vinyltrichlorosilane, 43.7 g of dimethyl monochlorosilane, 300 g of diethyl ether, 15 g of water and 1 g of chloroplatinic acid into the reaction kettle, and stir for 4 hours at 50° C.;

[0054] (B) Heating up to 150°C, vacuuming under reduced pressure to remove water and ether as a solvent, to prepare a hyperbranched polysiloxane active body.

[0055] (3) Preparation of carboxyl-terminated hyperbranched polysiloxane modified body:

[0056] (A) 30 g of difunctional carboxyl-terminated UV active monome...

Embodiment 3

[0061] (1) Preparation of difunctional carboxyl-terminated UV active monomers:

[0062] (A) Weigh 116g of hydroxyethyl acrylate, 178g of methylnadic acid anhydride and 0.294g of ammonium chloride into the reaction kettle, stir, and slowly heat up to 92°C in 25 minutes;

[0063] (B) heat preservation reaction for 4 hours to prepare a difunctional carboxyl-terminated UV active monomer.

[0064] (2) Preparation of hyperbranched polysiloxane active body:

[0065] (A) Add 3 g of vinyltrichlorosilane, 45 g of dimethyl monochlorosilane, 300 g of diethyl ether, 15 g of water and 1 g of phosphine coordination rhodium complex into the reaction kettle, and stir for 4.5 hours at 50° C.;

[0066] (B) Heating up to 130° C., vacuuming under reduced pressure to remove water and ether as a solvent, to prepare a hyperbranched polysiloxane active body.

[0067] (3) Preparation of carboxyl-terminated hyperbranched polysiloxane modified body:

[0068] (A) 20g of difunctional carboxyl-terminated...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com