Water-based alkyd resin and preparation method thereof

A technology of water-based alkyd resin and acid anhydride, applied in the field of coatings, can solve the problems of air pollution, resource and energy waste, etc., and achieve the effects of improving paint film adhesion, reducing gel phenomenon, and improving economic use value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

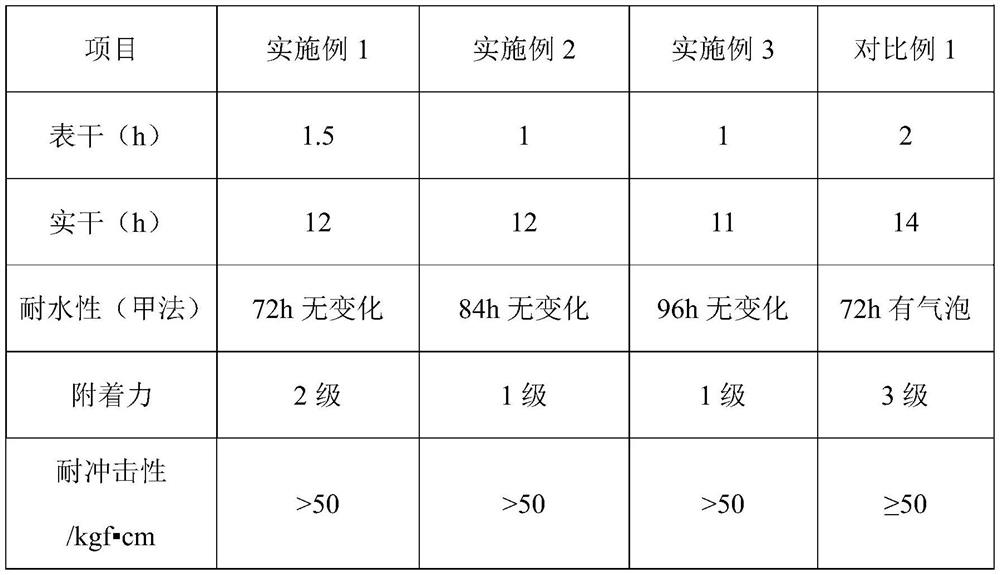

Examples

Embodiment 1

[0030] 29 parts by weight of the reaction raw materials linoleic acid, 12 parts by weight of pentaerythritol, 0.6 parts by weight of glycerol monomethyl ether, 16 parts by weight of isophthalic acid, and 2.11 parts by weight of xylene are added to the reaction with a water separator and a reflux condenser. In the flask, under the protection of nitrogen, stir and be heated to 160~240 ℃ to carry out esterification reaction 1~5 hour, until the acid value of reaction solution drops to 7~15mgKOH / g; Add the trimellitic anhydride of 4 parts by weight again (trimellitic anhydride is Increase the water-soluble functional monomer) and 2.11 parts by weight of xylene, and continue to react at a temperature of 170°C to 190°C until the acid value of the solution drops to 25 to 35mgKOH / g;

[0031] Distill the xylene under reduced pressure at a temperature of 150°C, add a neutralizing agent, control the pH of the reaction solution to 7-8, then add 20 parts by weight of co-solvent dimethyl glyc...

Embodiment 2

[0033] 31.2 parts by weight of the reaction raw materials linoleic acid, 18.55 parts by weight of pentaerythritol, 1.2 parts by weight of glycerol monomethyl ether, 18.42 parts by weight of isophthalic acid, and 3 parts by weight of xylene are added to the reaction with water separator and reflux condenser. In the flask, under the protection of nitrogen, stir and heat to 160-240°C for esterification reaction for 1-5 hours, until the acid value of the reaction solution drops to 7-15 mgKOH / g; then add 5.86 parts by weight of trimellitic anhydride and 3 parts by weight xylene, continue to react at a temperature of 170°C to 190°C until the acid value of the solution drops to 25 to 35mgKOH / g;

[0034] Distill the xylene under reduced pressure at a temperature of 150°C, add a neutralizing agent, control the pH of the reaction solution to 7-8, then add 30 parts by weight of co-solvent dimethyl glycerol, add water to the material and disperse it evenly at a high speed , to obtain wate...

Embodiment 3

[0036] 33 parts by weight of the reaction raw materials linoleic acid, 22 parts by weight of pentaerythritol, 1.8 parts by weight of glycerol monomethyl ether, 22 parts by weight of isophthalic acid, and 4 parts by weight of xylene are added to the reaction with water separator and reflux condenser. In the flask, under the protection of nitrogen, stir and heat to 160-240°C for esterification reaction for 1-5 hours, until the acid value of the reaction solution drops to 7-15 mgKOH / g; then add 8 parts by weight of trimellitic anhydride and 4 parts by weight xylene, continue to react at a temperature of 170°C to 190°C until the acid value of the solution drops to 25 to 35mgKOH / g;

[0037] Distill the xylene under reduced pressure at a temperature of 150°C, add a neutralizing agent, control the pH of the reaction solution to 7-8, then add 40 parts by weight of co-solvent dimethyl ether, and add water to the material and disperse it evenly at a high speed , to obtain water-based al...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com