Method for extracting nickel and cobalt from high-nickel battery waste

A battery, high-nickel technology, applied in the field of nickel-cobalt extraction from high-nickel battery waste, can solve the problems of difficulty in industrial production, high use cost, high price, etc., to ensure the separation efficiency of nickel and cobalt, improve production costs, reduce The effect of inventory

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

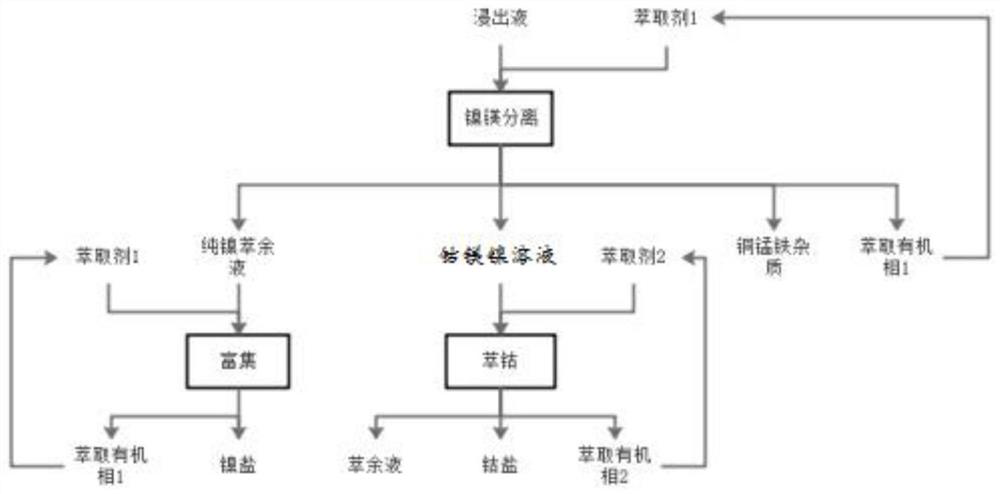

[0025] A method for extracting nickel and cobalt from waste materials of high-nickel batteries, specifically comprising the steps of:

[0026] Step S1: After crushing and sorting the waste high-nickel batteries, add sulfuric acid solution and hydrogen peroxide to the sorted waste high-nickel batteries, and soak them for 20 minutes at a temperature of 90°C to obtain a leaching solution;

[0027] Step S2: extracting the leach solution prepared in step S1 with extractant 1 at a volume ratio of 1:1 to obtain pure nickel raffinate and cobalt-magnesium-nickel solution;

[0028] Step S3: extracting the pure nickel raffinate prepared in step S2 with extractant 1 at a volume ratio of 1:1 to enrich nickel to obtain a nickel salt;

[0029] Step S4: Extract the cobalt-magnesium-nickel solution prepared in step S2 with an extractant 2 at a volume ratio of 1:1, and back-extract with a sulfuric acid solution with a concentration of 3mol / L to obtain a cobalt salt and a raffinate;

[0030] St...

Embodiment 2

[0032] A method for extracting nickel and cobalt from waste materials of high-nickel batteries, specifically comprising the steps of:

[0033] Step S1: After crushing and sorting the waste high-nickel batteries, add sulfuric acid solution and hydrogen peroxide to the sorted waste high-nickel batteries, and soak them for 20 minutes at a temperature of 90°C to obtain a leaching solution;

[0034] Step S2: extracting the leach solution prepared in step S1 with extractant 1 at a volume ratio of 1:2 to obtain pure nickel raffinate and cobalt-magnesium-nickel solution;

[0035] Step S3: Extract the pure nickel raffinate prepared in step S2 with extractant 1 to enrich nickel at a volume ratio of 1:2 to obtain nickel salt;

[0036] Step S4: Extract the cobalt-magnesium-nickel solution prepared in step S2 with an extractant 2 at a volume ratio of 1:2, and back-extract with a sulfuric acid solution with a concentration of 3.1mol / L to obtain a cobalt salt and a raffinate;

[0037] Step ...

Embodiment 3

[0039] A method for extracting nickel and cobalt from waste materials of high-nickel batteries, specifically comprising the steps of:

[0040] Step S1: After crushing and sorting the waste high-nickel batteries, add sulfuric acid solution and hydrogen peroxide to the sorted waste high-nickel batteries, and soak for 30 minutes at a temperature of 95°C to obtain a leaching solution;

[0041] Step S2: extracting the leach solution prepared in step S1 with extractant 1 at a volume ratio of 1:3 to obtain pure nickel raffinate and cobalt-magnesium-nickel solution;

[0042] Step S3: Extract the pure nickel raffinate prepared in step S2 with extractant 1 to enrich nickel at a volume ratio of 1:3 to obtain nickel salt;

[0043] Step S4: Extract the cobalt-magnesium-nickel solution prepared in step S2 with an extractant 2 at a volume ratio of 1:3, and back-extract with a sulfuric acid solution with a concentration of 3.2mol / L to obtain a cobalt salt and a raffinate;

[0044] Step S5: E...

PUM

| Property | Measurement | Unit |

|---|---|---|

| saponification | aaaaa | aaaaa |

| saponification | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com