Preparation method of prebaked anode dry material

A prebaked anode and dry material technology, applied in grain processing, etc., can solve the problems of polluting the environment, excessive sulfur content, etc., and achieve the effects of high yield, reduced sulfur content, and improved efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

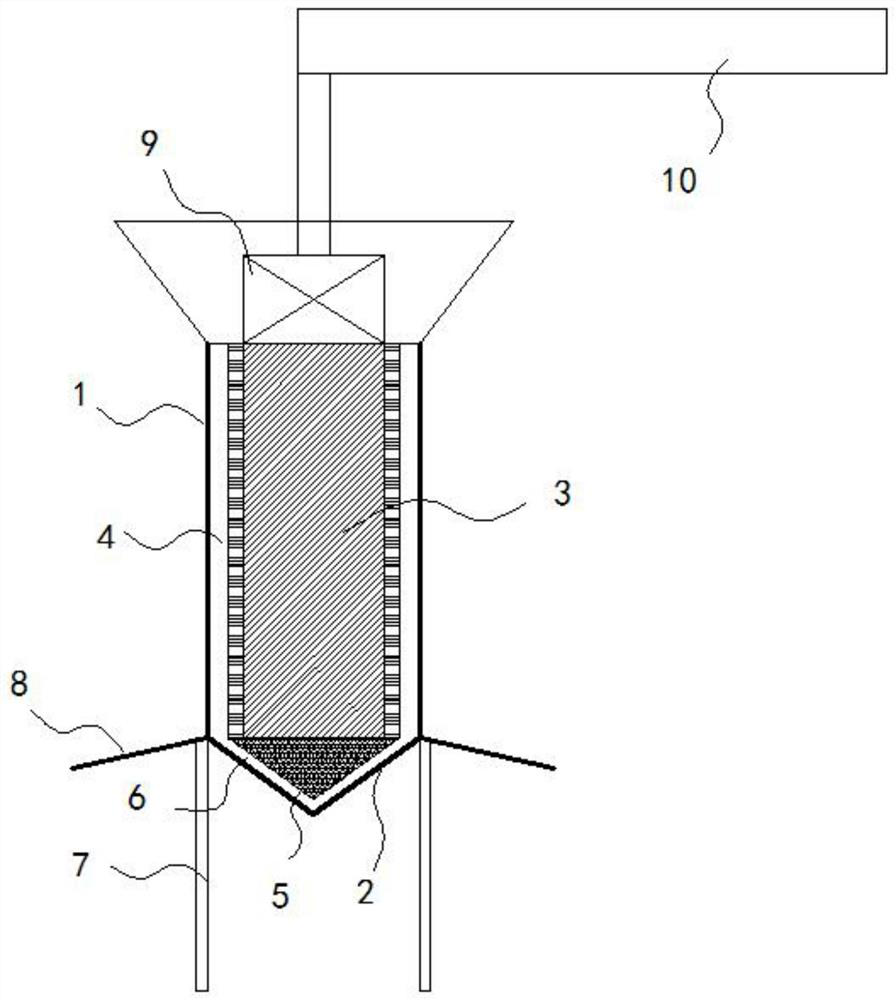

[0050] A method for preparing prebaked anode dry material, comprising:

[0051] Step 1, coarsely crushing the petroleum coke carbonaceous raw material in advance to a medium lump size of 50 mm to 70 mm, and then calcining to obtain calcined coke;

[0052] Step 2, crushing the obtained calcined coke to less than 70 mm to obtain petroleum coke particles, and sieving fine petroleum coke particles less than 3.15 mm and crude petroleum coke particles of 3.15 mm to 70 mm;

[0053] Step 3. Add a certain proportion of 3.15mm-70mm crude petroleum coke particles and petroleum coke carbonaceous raw materials below 50mm to the obtained fine petroleum coke particles below 3.15mm to form material A; wherein fine petroleum coke particles below 3.15mm account for 30% to 45% of the weight of material A;

[0054] Step 4, in addition, mixing 3.15mm-70mm crude petroleum coke particles with petroleum coke carbonaceous raw materials below 50mm to obtain material B;

[0055] Step 5: Melting the mo...

Embodiment 1

[0068] A method for preparing prebaked anode dry material, comprising:

[0069] Step 1. Crushing the petroleum coke carbonaceous raw material in advance to a medium size of 50 mm to 70 mm and then calcining to obtain calcined coke; the moisture content of the petroleum coke carbonaceous raw material is 1.2% to 3.0%; the volatile content of the petroleum coke carbonaceous raw material is divided into 8.0% to 9.8%; the ash content of the petroleum coke carbonaceous raw material is 0.30% to 0.50%; the sulfur content of the petroleum coke carbonaceous raw material is 0.70% to 2.3%.

[0070] Step 2, crushing the obtained calcined coke to less than 70 mm to obtain petroleum coke particles, and sieving fine petroleum coke particles less than 3.15 mm and crude petroleum coke particles of 3.15 mm to 70 mm;

[0071] Step 3. Add a certain proportion of 3.15mm-70mm crude petroleum coke particles and petroleum coke carbonaceous raw materials below 50mm to the obtained fine petroleum coke p...

Embodiment 2

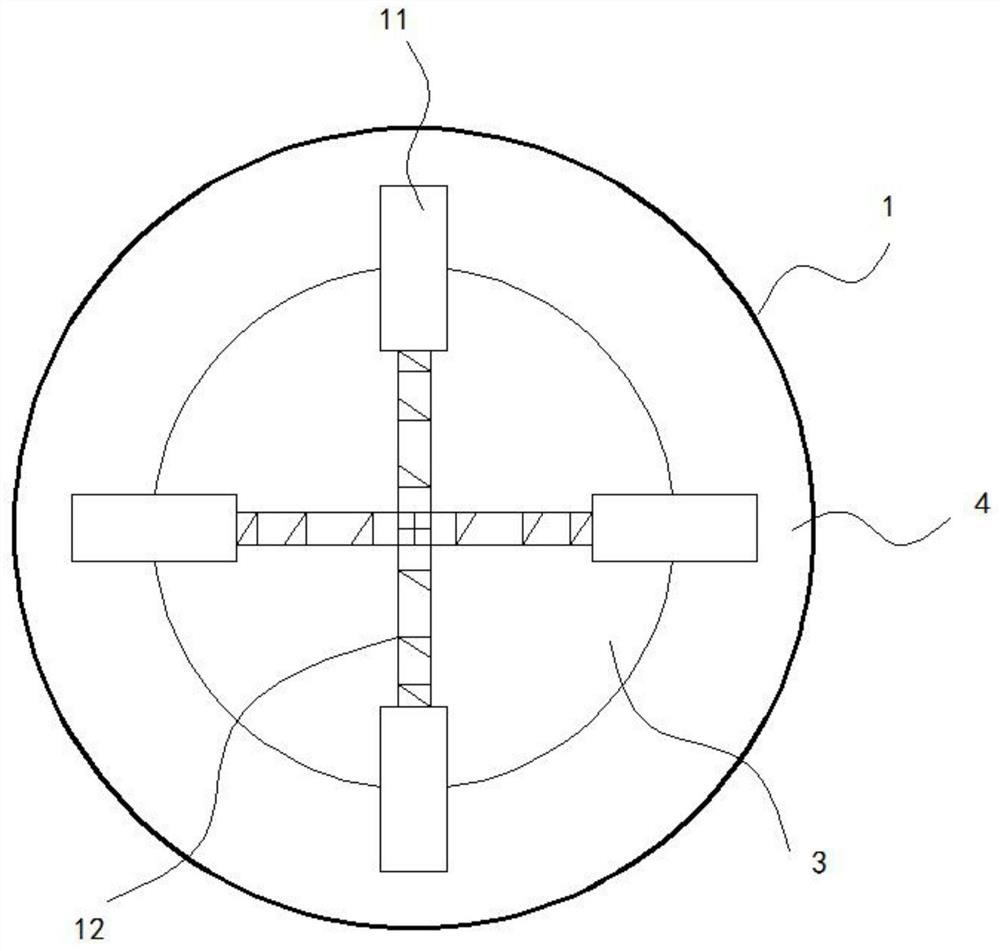

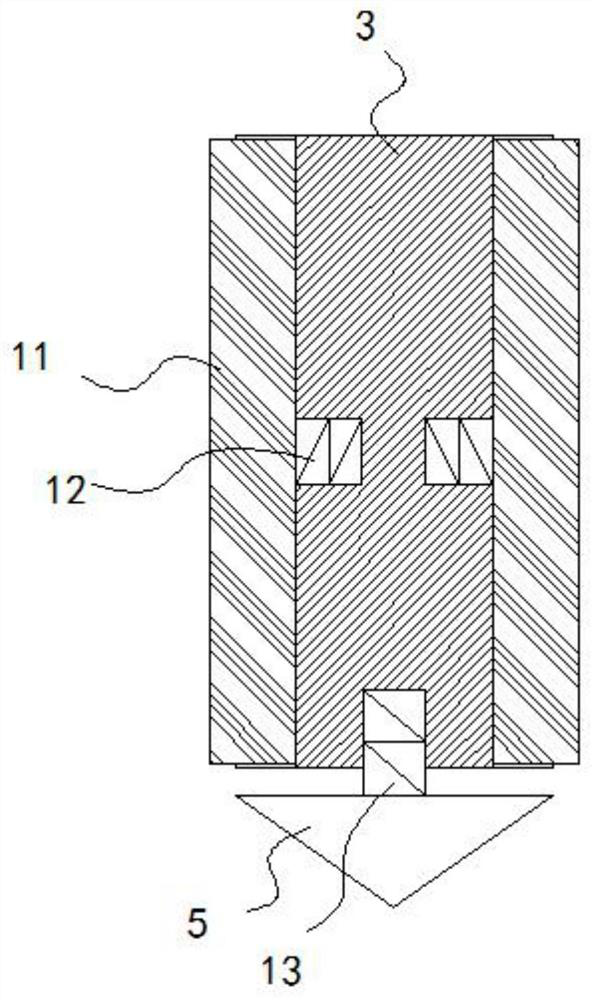

[0078] The difference from Example 1 is that the above-mentioned crushing device is used to crush the petroleum coke carbonaceous raw material and calcined coke, so as to improve the crushing efficiency and reduce the traditional crushing process.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| density | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com