Pipe string structure and process method for integration of injection and production of heat-insulated canned electric submersible pump

A technology of submersible electric pump and thermal insulation oil pipe, which is used in isolation devices, production of fluids, geothermal power generation, etc., to avoid cold damage, improve production efficiency and safety level, and achieve the effect of seamless conversion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

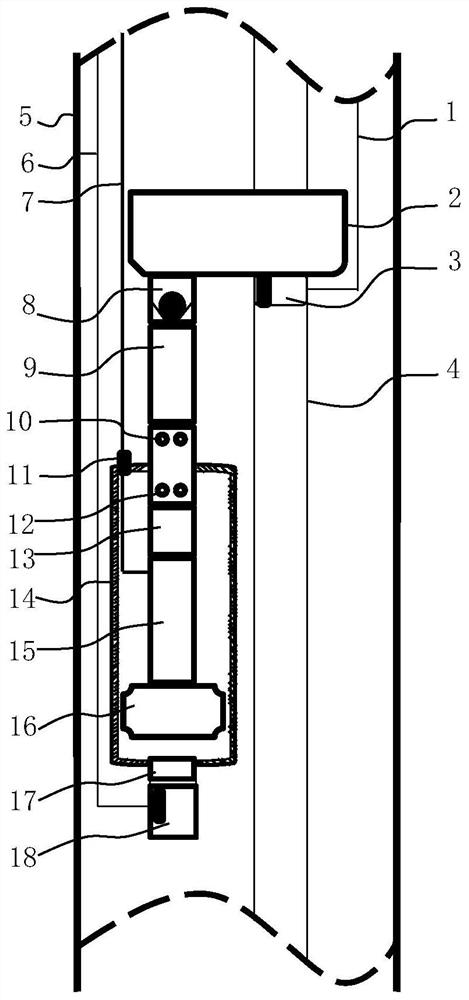

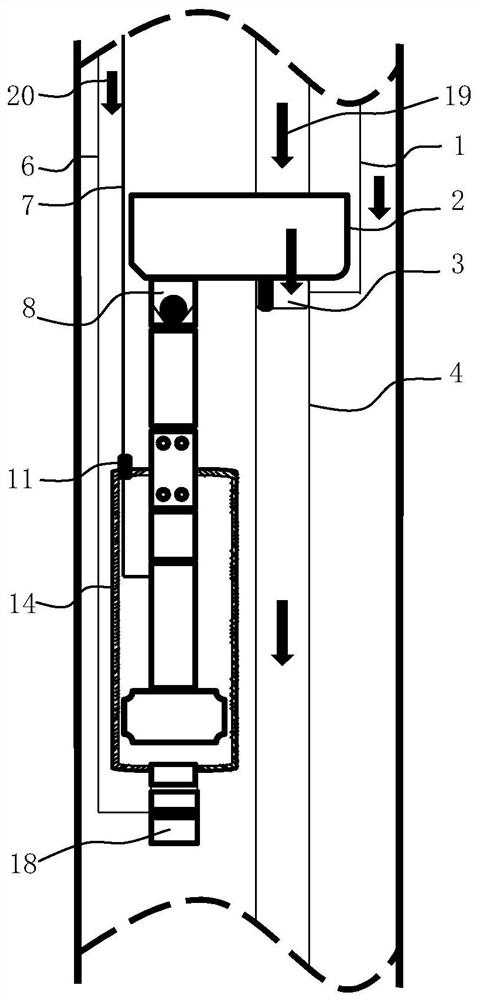

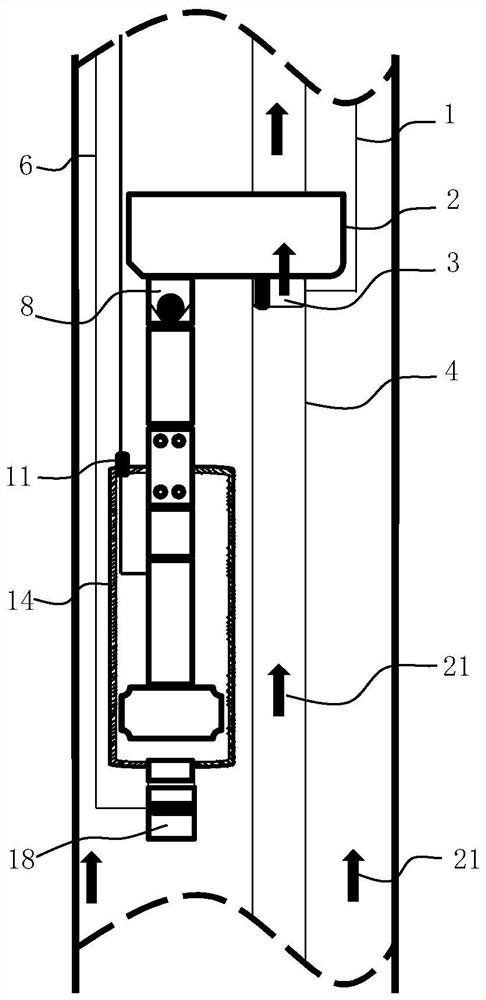

[0046] In order to better understand the purpose, structure and function of the present invention, a further detailed description will be given below of a pipe string structure and process for the integration of injection and production of a heat-insulated canned submersible electric pump according to the present invention in conjunction with the accompanying drawings.

[0047] Such as Figure 1-Figure 4 As shown, the integrated pipe string structure of the heat-insulated canned electric submersible pump of the present invention includes: a process pipe string installed in the production casing 5, a pipe string joint 2 connected with the process pipe string, from top to bottom The injection-production reversing valve 3 installed on the side of the pipe string joint 2, the heat-insulated oil pipe 4 for injecting steam and the heat-insulating collar installed under the injection-production reversing valve 3; the pipe string joint 2 is installed from top to bottom Check valve 8, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com