Device and method for manufacturing rock joints with different roughness

A technology of rock joints and roughness, applied in the field of geotechnical engineering, can solve the problems of low success rate, single roughness, low strength, etc., and achieve the effects of low cost, avoidance of pressure eccentricity, and simple production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

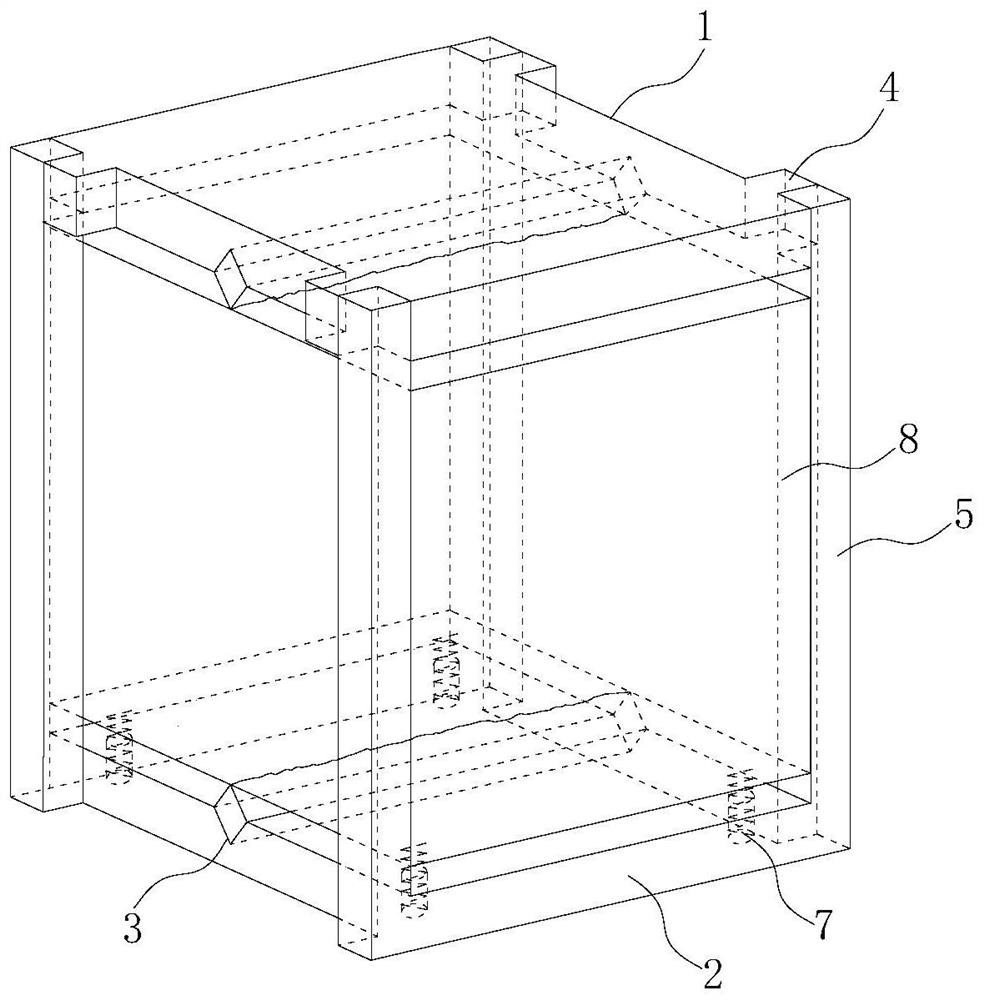

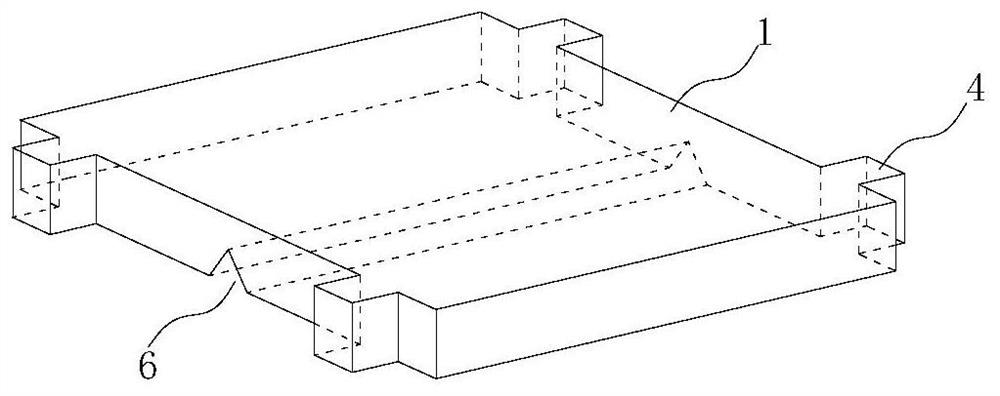

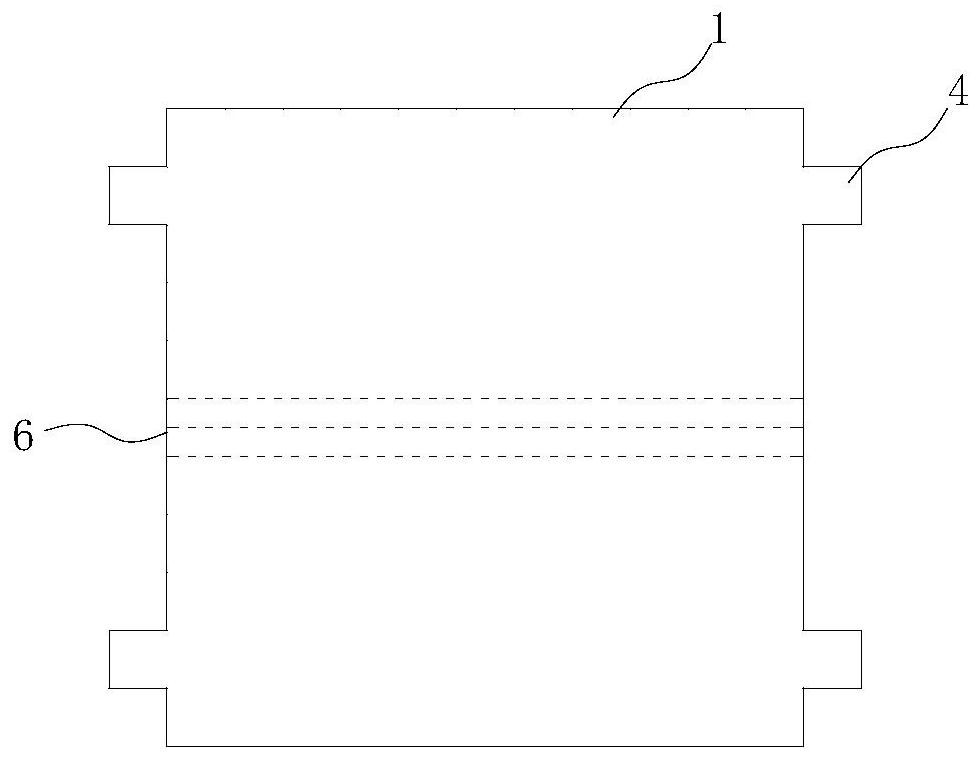

[0039] combine Figure 1 to Figure 9 As shown, the specific implementation of a device and method for making rock joints with different roughness provided by the present invention will be described.

[0040] The existing method of splitting the joint surface formed by the obtained rock joints has a single roughness, and it is impossible to make rock joint surfaces with different roughness characteristics, so the mechanical properties, deformation characteristics and permeability of jointed rock masses with different roughness characteristics are limited. characteristic research.

[0041]This embodiment provides a device for making rock joints with different roughnesses, which specifically includes an upper pressing plate and a lower pressing plate for transferring loads. The upper and lower pressing plates are respectively provided with vertically parallel V-shaped grooves in the middle, and the pressing bars are engaged. Placed in the V-shaped groove, the bead can be fixed t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com