Hydraulic system of high-ground-clearance spraying machine

A hydraulic system and sprayer technology, applied in the field of high ground clearance sprayer hydraulic system, can solve the problems such as obstacles to the flexibility of the automatic control horizontal whole machine, difficulty in turning and turning around, and great damage to the seedling bed, so as to avoid oil overflow The effect of heat generation, flexible steering mode and less damage to the seedling bed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with accompanying drawing.

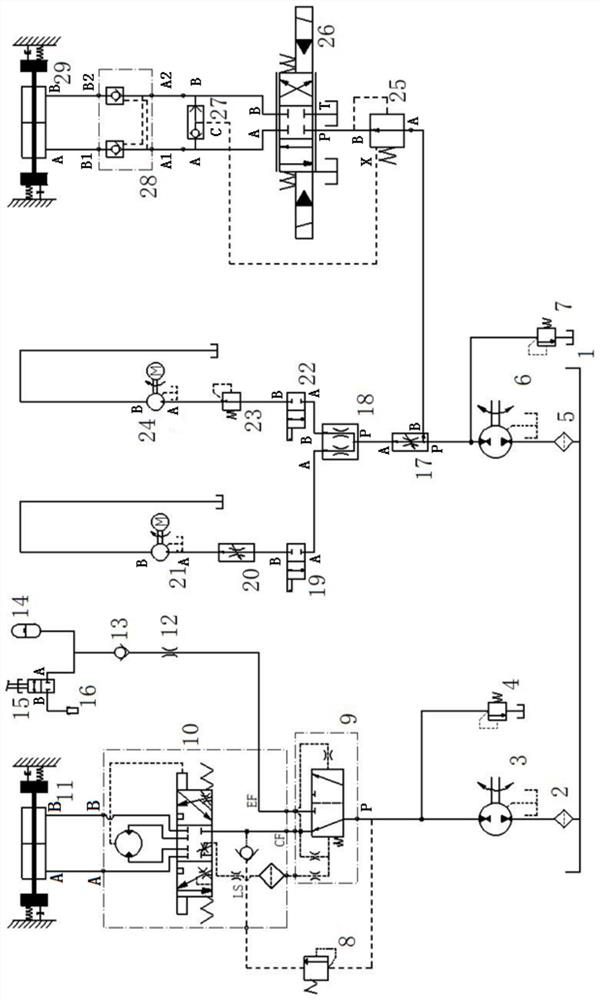

[0025] Such as figure 1 As shown, the present invention provides a high ground clearance sprayer hydraulic system, including a first hydraulic pump 3, an oil tank 1, a priority valve 9, a hydraulic steering gear 10, a front wheel steering hydraulic cylinder 11, a fixed throttle 12, and a one-way valve 13. Accumulator 14, first reversing valve 15, second hydraulic pump 6, one-way stable diverter valve 17, diverter valve 18, second reversing valve 19, third reversing valve 22, speed regulating valve 20, Fertilizer throwing hydraulic motor 21, fixed value pressure reducing valve 23, spray hydraulic motor 24, fixed differential pressure reducing valve 25, fourth reversing valve 26, hydraulic control one-way valve group 28, rear wheel steering hydraulic cylinder 29 and shuttle valve 27 ;

[0026] The oil inlet and the oil outlet of the first hydraulic pump 3 are respectively c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com