Process for preparing protein powder from rice

A technology of protein powder and process, which is applied in the direction of protein food components, protein components of waste, food science, etc., can solve the problems of affecting the filtering effect, rack wear, track wear, etc., to reduce post-processing pressure and reduce operation Cost, the effect of extending the industrial chain

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

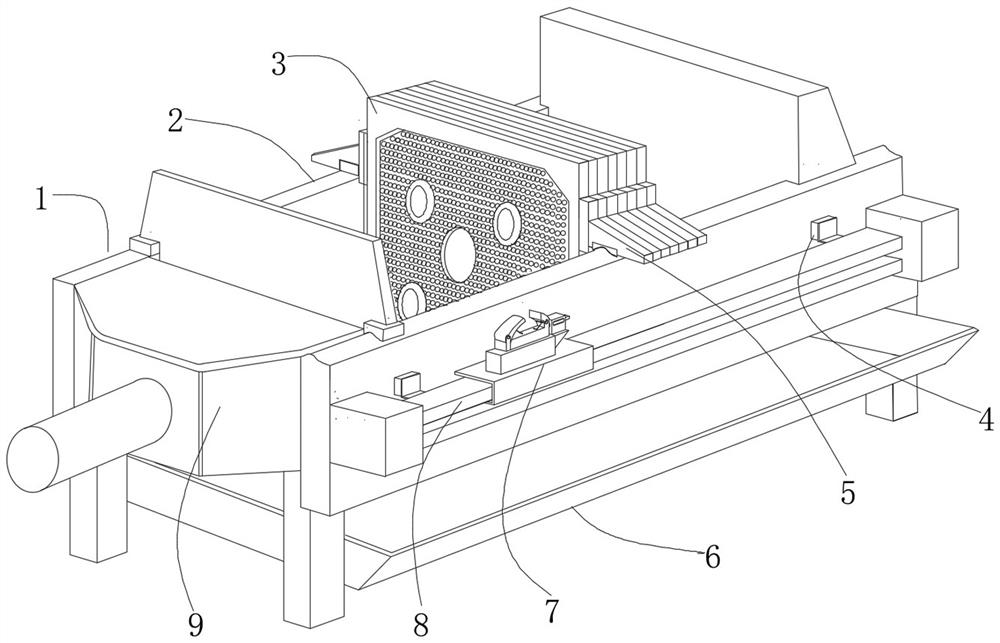

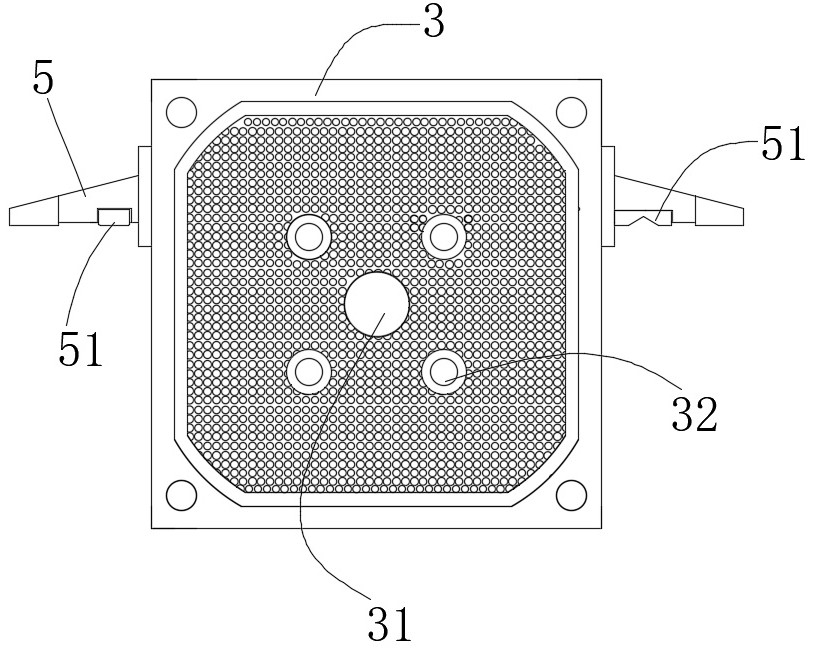

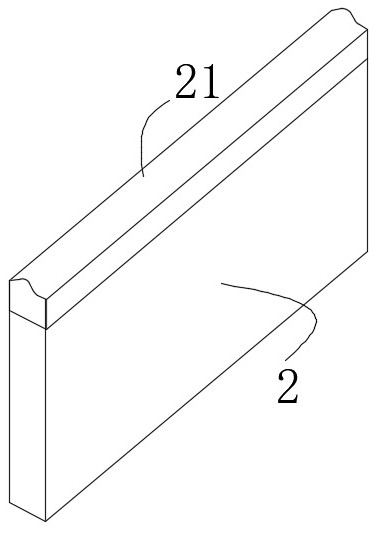

Image

Examples

Embodiment Construction

[0029] The rice protein powder preparation process comprises the following steps:

[0030] (1) Choose non-transgenic broken rice, soak in water for 2-4 hours, grind the broken rice to a particle size of 40-80 mesh with a grinder to obtain rice milk, and the ratio of rice flour and water in the rice milk is 1:2-4 (parts by weight). Said non-GMO rice is usually imported from Thailand or Vietnam. The water used in this step is normal temperature tap water.

[0031] (2) Pour the rice milk into the sealed tank, add 0.6-0.8‰ amylase to the rice milk in parts by weight, stir evenly, heat to 105°C-108°C, and keep it for 5-10 minutes, then enter the laminar flow tank, in the layer Keep it in the flow tank for 2-3 hours to enzymatically hydrolyze the starch in the rice flour into sugars. The amylase added may be alpha-amylase and / or beta-amylase. The enzymatic solution can be heated to 65-80°C and sealed for 10-30 minutes to inactivate the amylase. In this step, the rice milk is hea...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size (mesh) | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com