Shaft mill

A mill and shaft grinding technology, which is applied in the fields of smoke removal, pollution prevention, grain processing, etc., can solve the problems of secondary pollution, machine damage, increased wear of the body and liner, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

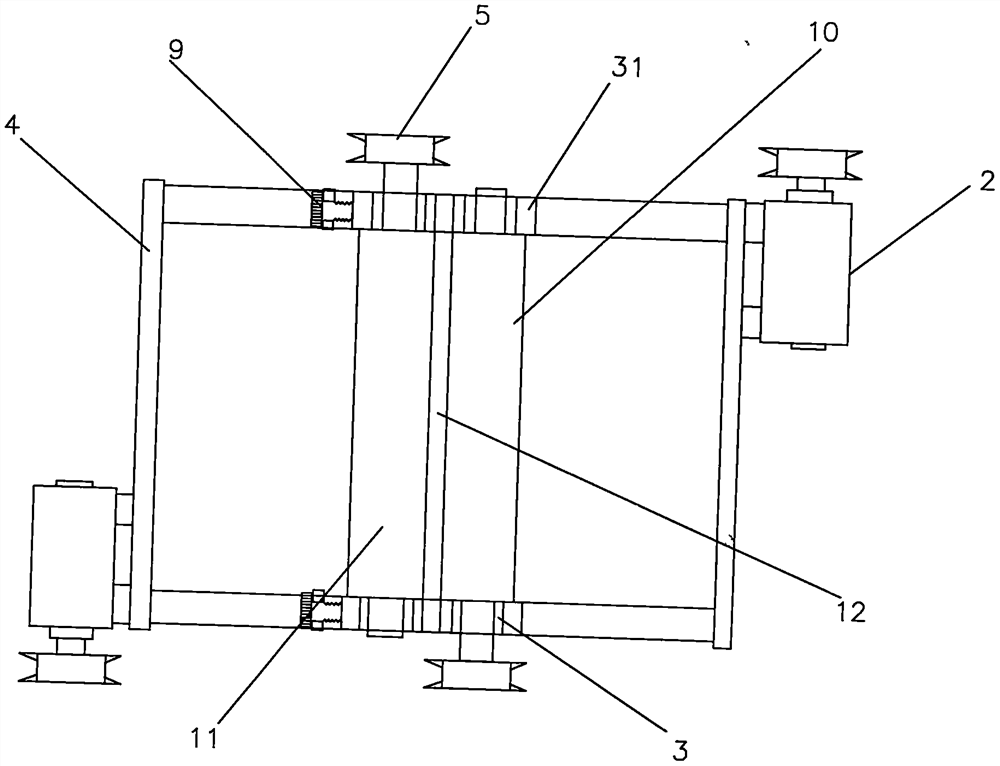

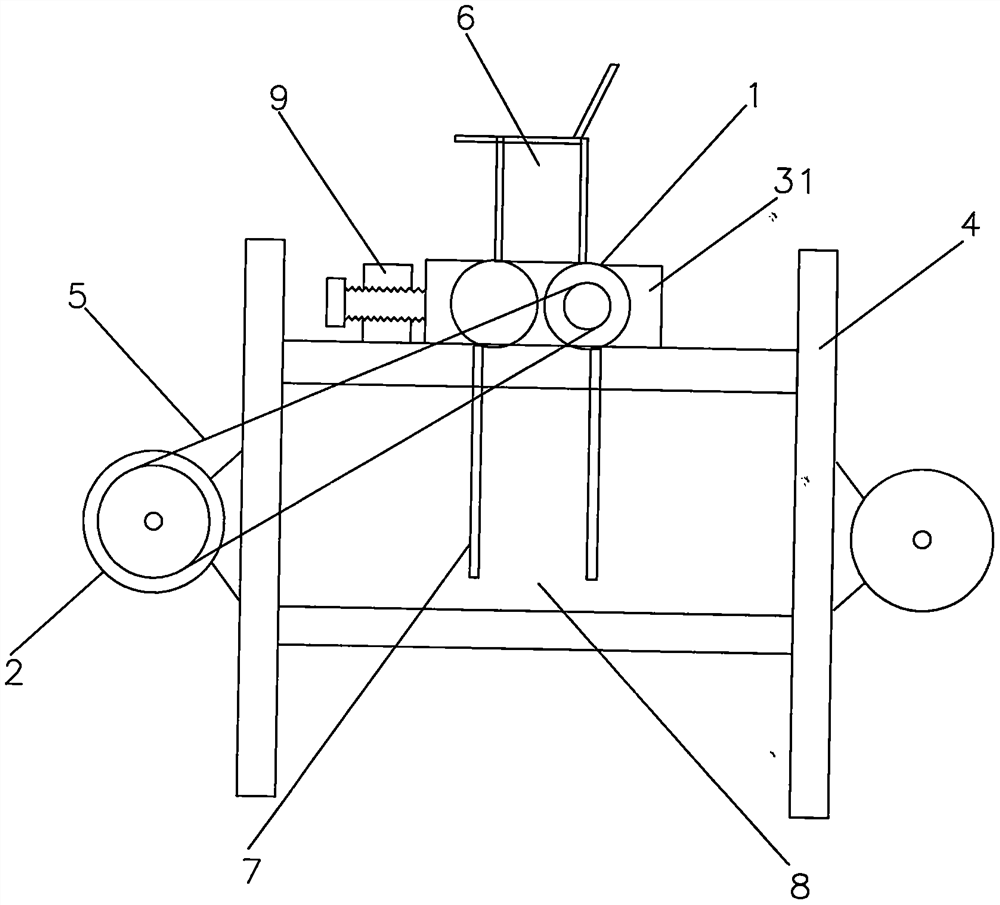

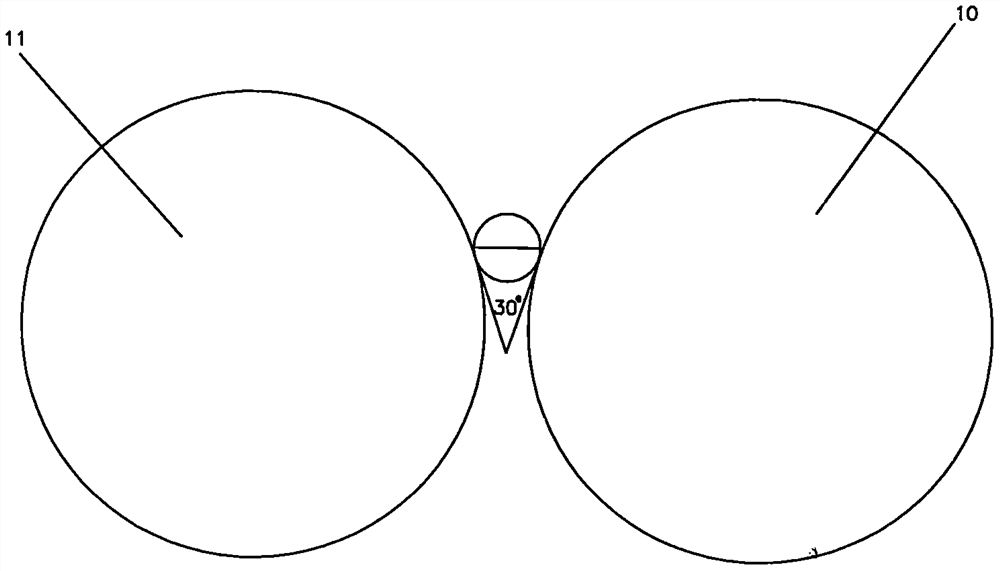

[0045] Implementation column 1, such as figure 1 , figure 2 , image 3 , Figure 4 , Figure 5 with Image 6 As shown in the figure: a shaft mill is in the shape of a cabinet and generally has four legs. The frame 4 of the mill is wrapped with a shell to form a cabinet shape. The frame 4 uses several thick square steel beams or steel plates to make a combined frame. Generally, four square steel beams with relatively thick dimensions are used as vertical columns, and the four columns are separated by a certain distance, and are fastened and connected with horizontal square steel beams and vertical square steel beams. The beam and the longitudinal square beam steel are the beam and the longitudinal beam of the frame 4. The beam is generally a double-beam structure, and a pair of square steels are arranged side by side with a certain gap to form the beam. The gap can be used for the bearing holder 31 of the movable grinding shaft 11 as a horizontal Easy to move and fasten w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com