Stainless steel plate oil injection production line and oil injection method thereof

A stainless steel plate and production line technology, applied in chemical instruments and methods, cleaning methods and utensils, paint spray booths, etc., can solve the problem of poor oil injection effect of stainless steel plates, weak surface grease adsorption capacity of stainless steel plates, affecting the efficiency of titanium plating on stainless steel plates And the effect and other issues, to improve the cleaning efficiency and fuel injection efficiency, improve the effect, uniform cleaning and fuel injection effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment 1

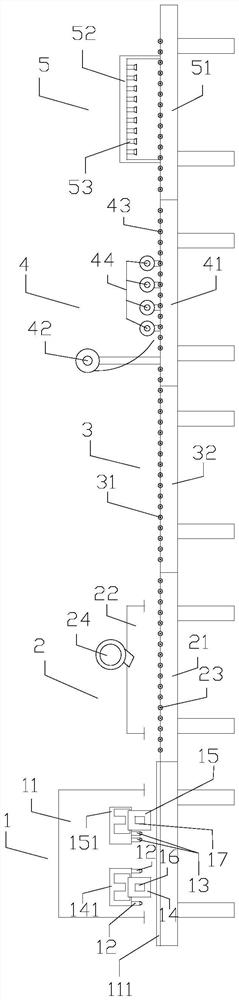

[0030] Such as Figure 1-2 As shown, the oil injection production line for stainless steel plates includes a cleaning oil injection machine 1, a dryer 2, a cooling conveyor 3, a film laminating machine 4, and a reclaimer 5 arranged in sequence along the processing direction. The cleaning oil injection machine 1 is used for For cleaning and spraying the steel strip, the dryer 2 is used for drying the steel strip after the spraying treatment, and the cooling conveyor 3 is used for drying the steel strip after the drying treatment. Perform cooling treatment, the film laminating machine 4 is used for laminating the steel strip after the cooling treatment, and the reclaimer 5 is used for reclaiming the steel strip after the film laminating treatment.

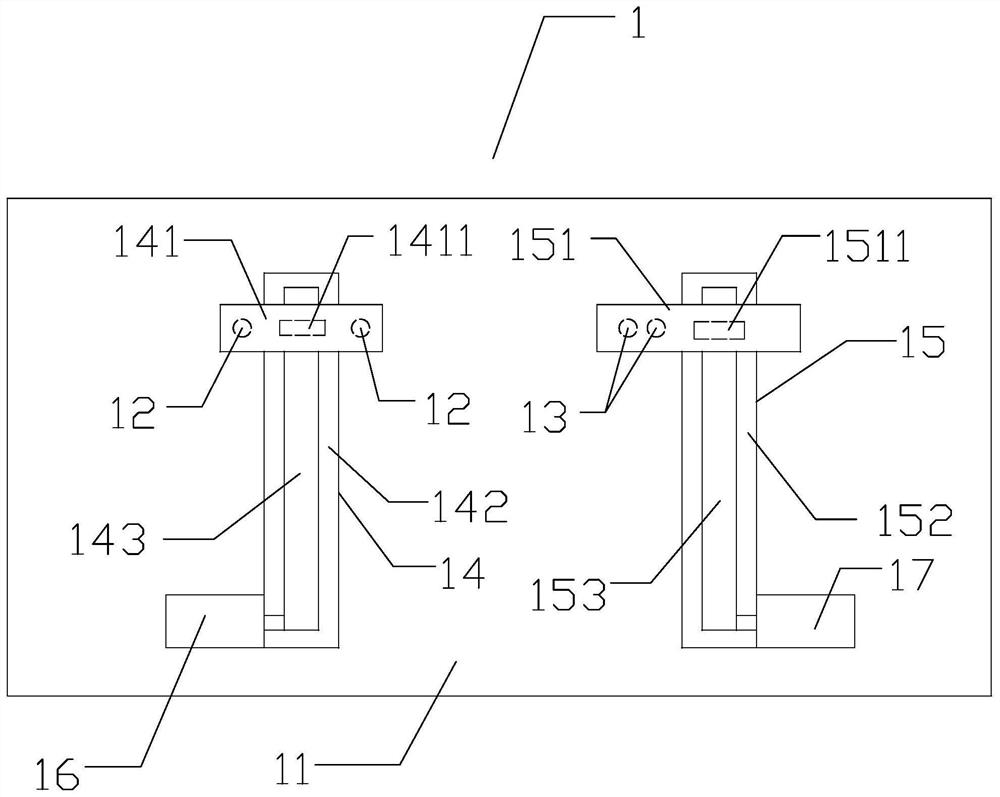

[0031] Wherein, the cleaning fuel injection machine 1 includes a fuel injection cavity 11, and a plasma spray gun 12 and a fuel spray gun 13 are arranged in the fuel injection cavity 11, and the plasma spray gun 12 and the fuel spray...

specific Embodiment 2

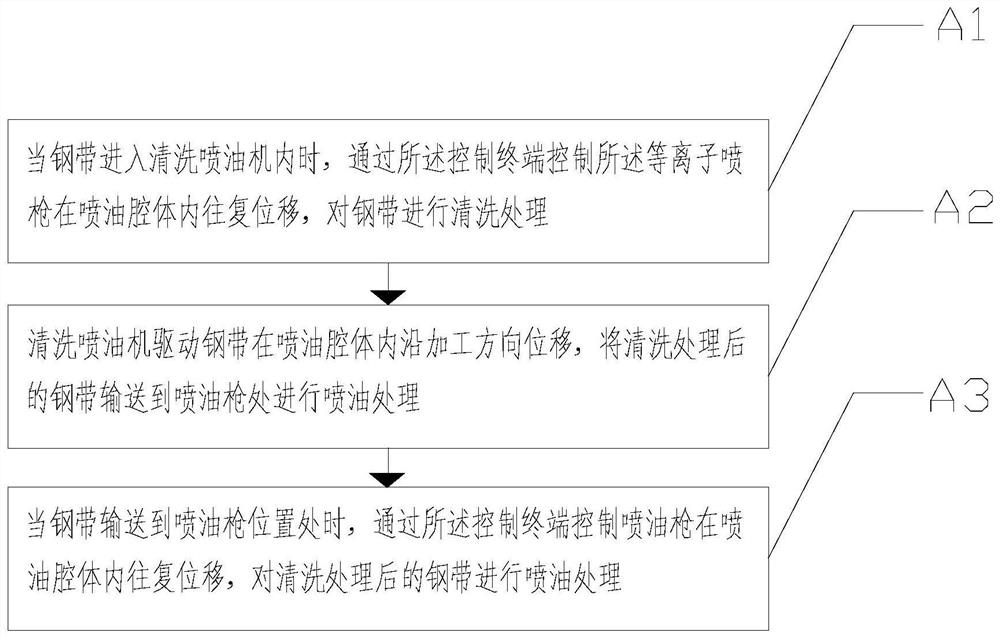

[0048] Such as image 3 As shown, the present invention also includes the fuel injection method of the stainless steel plate fuel injection production line of the above-mentioned specific embodiment 1, including a control terminal arranged on the cleaning fuel injection machine 1, and the control terminal is connected to the plasma spray gun 12 respectively. Electrical connection with the fuel injection gun 13 includes the following steps:

[0049] A1: When the steel strip enters the cleaning fuel injection machine 1, the plasma spray gun 12 is controlled to move back and forth in the fuel injection chamber 11 through the control terminal to clean the steel strip;

[0050] A2: Cleaning fuel injection machine 1 drives the steel belt to move along the processing direction in the fuel injection chamber 11, and transports the cleaned steel belt to the fuel injection gun 13 for fuel injection treatment;

[0051] A3: When the steel strip is transported to the position of the oil sp...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com