Power take-off control system, method and device, electronic equipment and storage medium

A technology of a control system and a control method, which is applied in the directions of control devices, fluid pressure actuation devices, fluid pressure actuation system components, etc., can solve the problems of shortening battery life, low battery power utilization, and increasing use costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

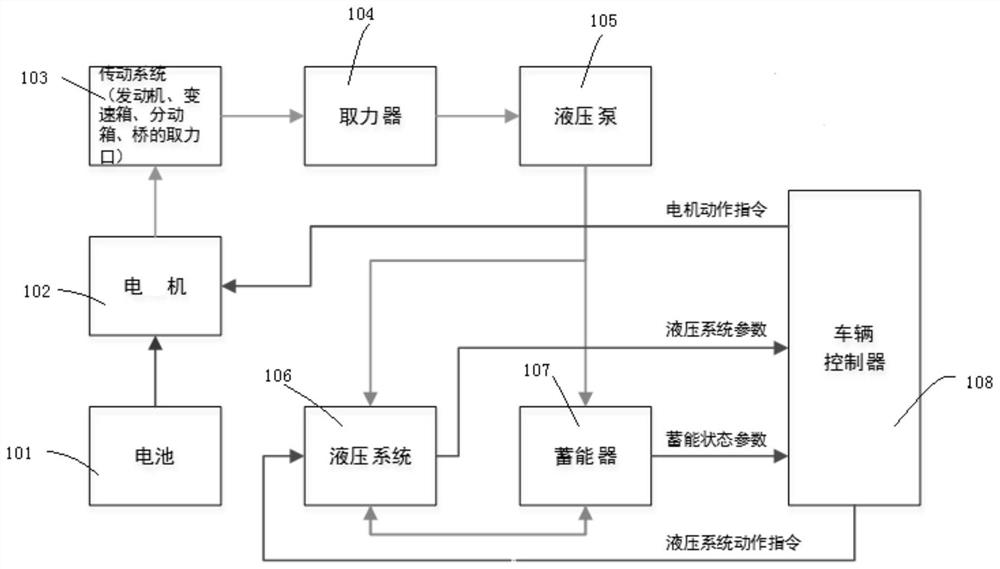

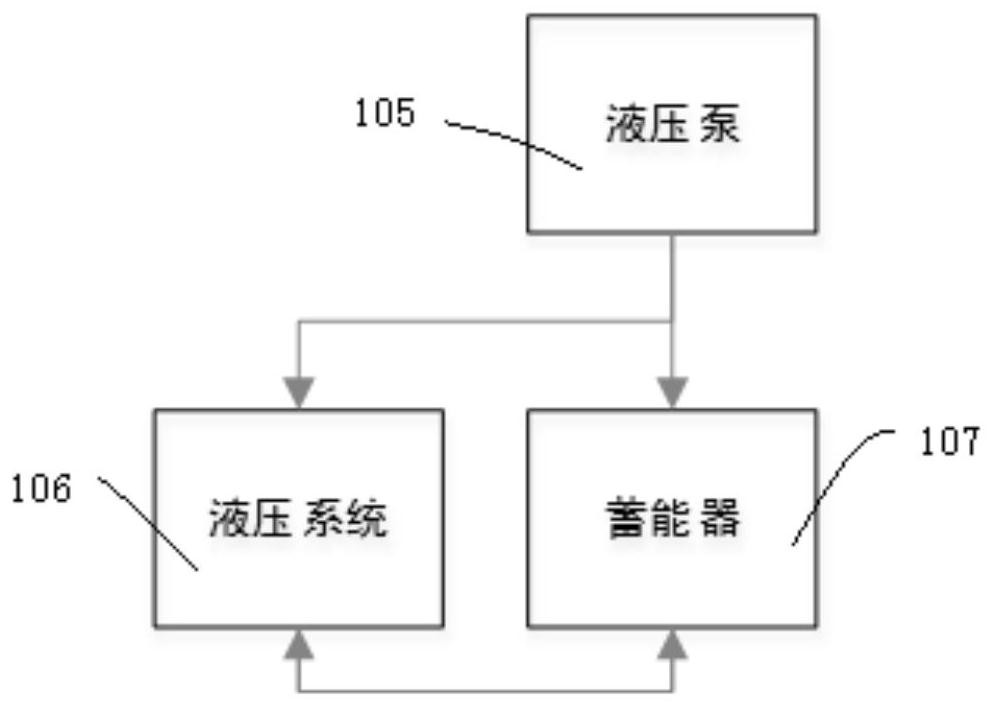

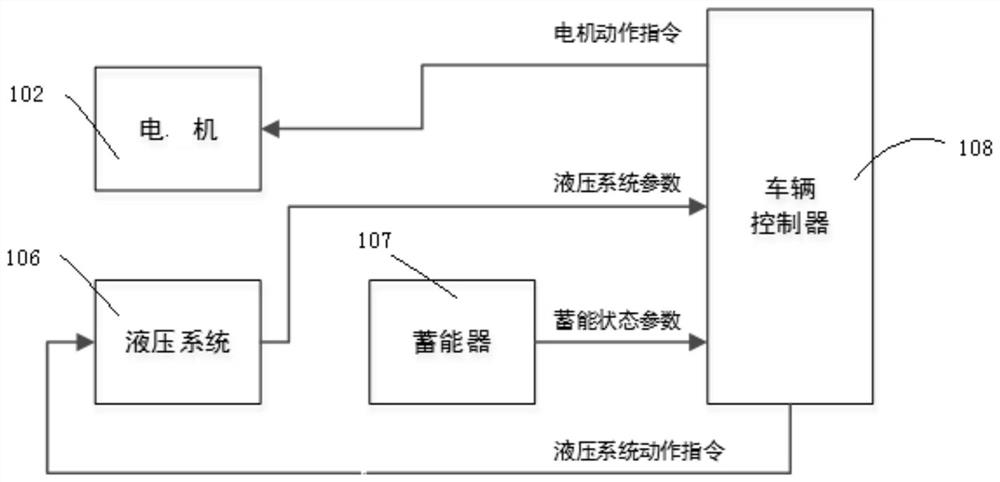

[0067] Please see figure 1 , figure 1 It is a structural block diagram of a power take-off control system provided in the embodiment of this application. This system can be applied to the power take-off control of a crane. The system specifically includes a motor 102, a hydraulic pump 105, a hydraulic system 106, an energy storage device, and a vehicle controller 108. The specific connections are as follows:

[0068] The battery 101 is electrically connected to the motor 102 through a power circuit, and is used to provide energy to the motor 102; the input end of the transmission system 103 is connected to the motor 102, and the output end of the transmission system 103 is connected to the input end of the power take-off 104. The output end of the device 104 is connected to the hydraulic pump 105 in transmission, and the hydraulic pump 105 is connected to the hydraulic system 106 through a hydraulic oil circuit, so that the motor 102 provides energy to the hydraulic system 10...

Embodiment 2

[0077] The embodiment of this application provides a power take-off control method, which is applied to the vehicle controller 108 in Embodiment 1, such as Figure 4 As shown, it is a flow chart of the power take-off control method, and the method may specifically include the following steps:

[0078] Step S100: Receive a power take-off state feedback signal to determine whether it is in a power take-off state;

[0079] The power take-off status feedback signal is used to reflect whether it is in the power take-off state, and the opening and closing of the power take-off state can also be controlled through the opening and closing of the switch valve.

[0080] Step S200: If yes, receive the working state parameters of the hydraulic system 106;

[0081] Step S300: judging whether the hydraulic system 106 is in a working state according to working state parameters;

[0082] In the power take-off state, the working state parameters of the hydraulic system 106 are received. The ...

Embodiment 3

[0102] The embodiment of this application provides a power take-off control device, which is applied to the vehicle controller 108 in Embodiment 2, such as Figure 7 Shown is the structural block diagram of the power take-off control device, which includes:

[0103] The signal receiving module 100 is used to receive the power take-off state feedback signal to determine whether it is in the power take-off state;

[0104]The parameter receiving module 200 of the hydraulic system 106 is configured to receive the working state parameters of the hydraulic system 106 if it is in the power take-off state;

[0105] A working state judging module 300, configured to judge whether the hydraulic system 106 is in a working state according to the working state parameters;

[0106] An action command sending module 400, configured to send the motor 102 an action command to the motor 102 if the hydraulic system 106 is in a working state;

[0107] A first energy judging module 500, configured...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com