A kind of preparation method of polyurethane composite material

A composite material and polyurethane technology, which is applied in the field of polyurethane composite material preparation using high pressure injection molding process, can solve the problems of insufficient flame retardant performance, insufficient heat resistance, slow molding speed, etc., and achieves good dimensional stability and resistance. Excellent flammability and short demolding time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

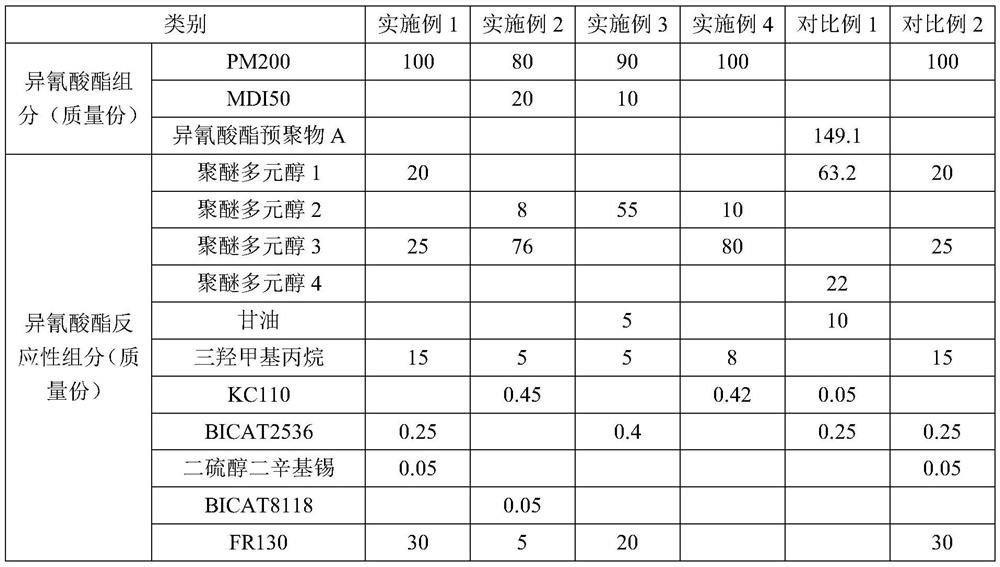

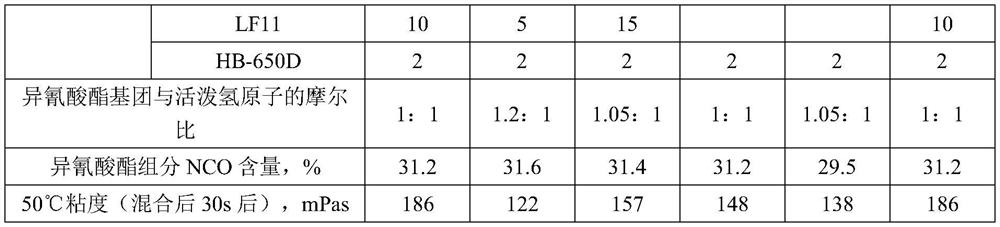

[0041] The raw materials used in the examples and comparative examples are as follows:

[0042] Isocyanates:

[0043] WANNATE PM200, NCO content 31.2wt%, viscosity 200mpa.s at 25℃, Wanhua Chemical,

[0044] WANNATE MDI50, NCO content 33.5wt%, viscosity 10mpa.s at 25℃, Wanhua Chemical,

[0045] Isocyanate prepolymer A, NCO content 29.5wt%, viscosity 145mpa.s at 25°C, obtained by reaction of isocyanate compound and polyester polyol, the isocyanate compound is a mixture of WANNATE PM200 and WANNATE MDI50, the polyester polyol The hydroxyl value is 56mgKOH / g, and the functionality is 2;

[0046] Polyether polyol 1, starting with glycerin, hydroxyl value 560mgKOH / g, propylene oxide polymerization, viscosity 350mpa.s at 25°C;

[0047] Polyether polyol 2, starting with glycerin, hydroxyl value 420mgKOH / g, propylene oxide polymerization, viscosity 380mpa.s at 25°C;

[0048] Polyether polyol 3, starting with glycerin, hydroxyl value 336mgKOH / g, propylene oxide polymerization, visco...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

| hydroxyl value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com