A method for artificial synthesis of fluid inclusions in quartz

A fluid inclusion and artificial synthesis technology, which is applied in the field of geological fluid research in geosciences, can solve the problems of small number of inclusions, denudation, non-round shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

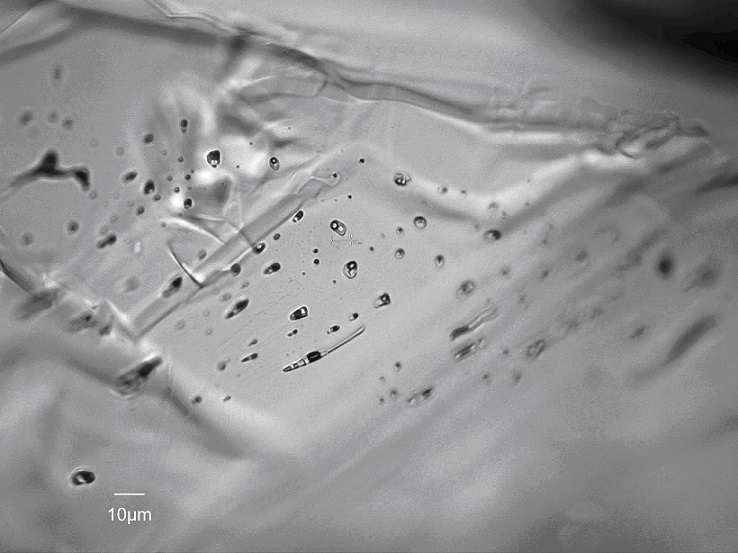

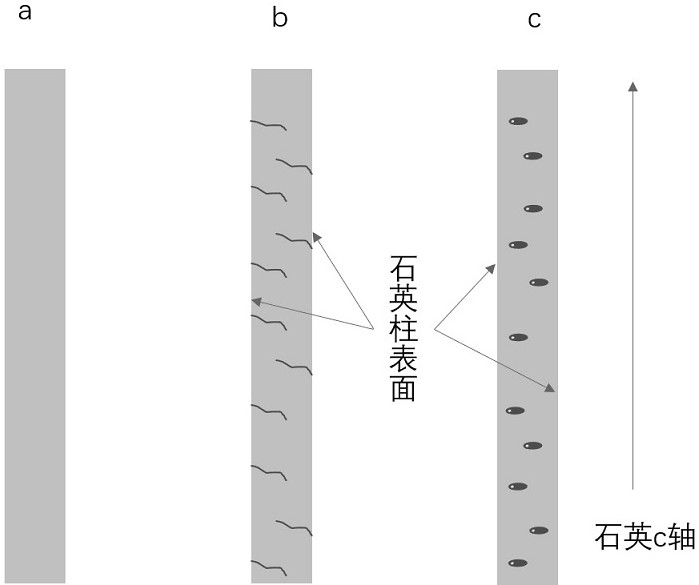

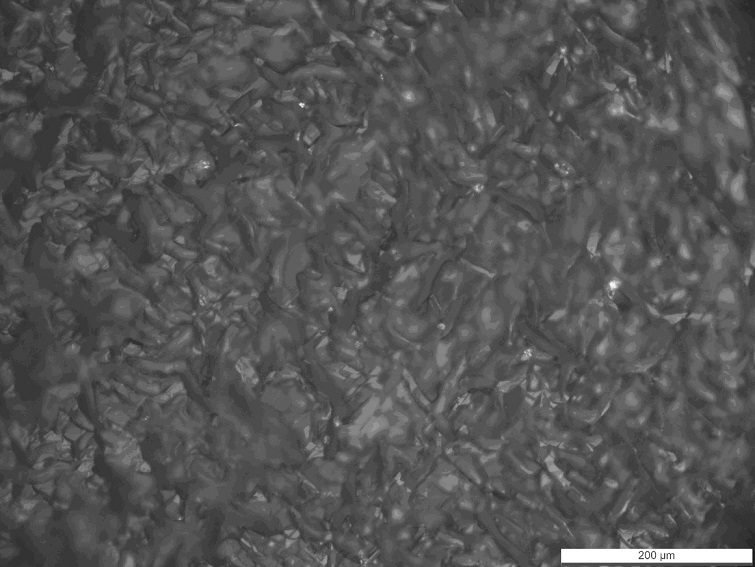

[0023] refer to Figure 1-4 , a method for artificially synthesizing fluid inclusions in quartz, comprising the following steps:

[0024] Step 1: Cut the natural quartz crystal without inclusions into a cuboid of 3mm*3mm*10mm along the growth direction of the quartz crystal with a diamond low-speed saw, which is the quartz column;

[0025] Step 2: Grind the cut cuboid quartz column on a 60-mesh diamond grinding disc for 10-15 minutes to make some irregular grooves on the surface;

[0026] Step 3: corrode the cuboid quartz column in step 2 in alkaline solution, the etching method is: prepare 55wt% NaOH solution and place it in a Teflon bushing, place the ground quartz column in step 2 in NaOH solution , and then the Teflon bushing was placed in a stainless steel autoclave, and then the stainless steel autoclave was placed in an oven at 160 ° C and the pressure was the saturated vapor pressure of water for 12 hours, so that the groove of the quartz column was deepened. The sur...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com