Automatic positioning control system and method for steelmaking scrap steel platform car

An automatic positioning and control system technology, applied in general control systems, control/regulation systems, program control in sequence/logic controllers, etc. With conditions and other issues, to achieve the effect of reducing control costs, reducing labor intensity, and low input costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

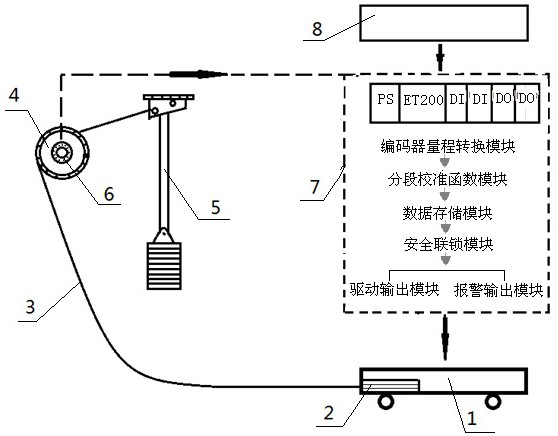

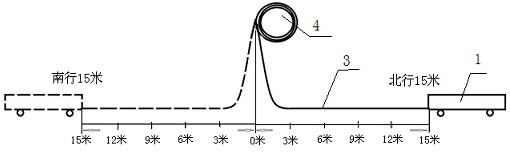

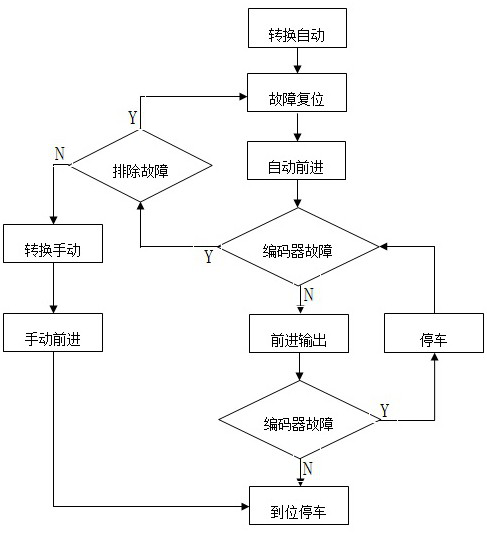

[0058] This embodiment is an automatic positioning control system for steel scrap platform trucks, with a stroke of 30 meters. The platform truck 1 runs north-south, stops at 15 meters when traveling south, and stops at 15 meters when traveling north.

[0059] Transmission motor 2: YZR225M-8

[0060] Tolan 5: JYFFG 3*16

[0061] Reel 4 (hammer type cable reel): ZCJ-40-II

[0062] Scrap car: 60T

[0063] Encoder 6: OMRON (E6C3-AG5B 256P / R 1M), resolution: 256P / R (8 bits), output mode: PNP open collector output, output code: Gray code.

[0064] PLC hardware: IM153-1(6ES7 153-1AA03-0XB0), DI32(6ES7 321-1BL00-0AA0), DO32(6ES7 322-1BL00-0AA0), PS307 5A(6ES7 307-1EA00-0AA0).

[0065] Operation box 8: automatic manual transfer switch, fault reset, automatic southbound button, automatic northbound button, automatic stop button, manual jog southbound button, manual jog northbound button, automatic indicator light, manual indicator light, southbound Indicator light, northbound indic...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com