Mesoporous hollow carbon micron cage material, and preparation method and application thereof

A hollow and mesoporous technology, applied in the preparation/purification of carbon, hybrid capacitor electrodes, etc., can solve problems such as environmental pollution and human health threats, achieve high purity, avoid pollution and threats to the human body, and low energy consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

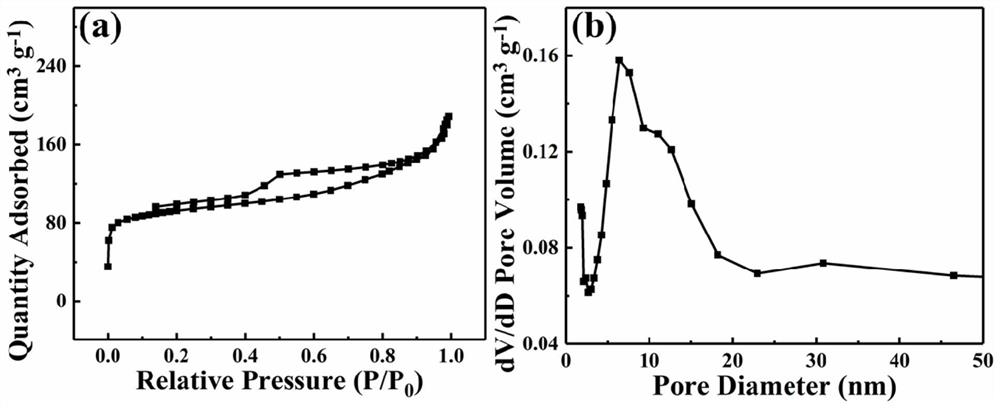

[0028] A method for preparing a mesoporous hollow carbon micro-cage material of the present invention comprises the following steps:

[0029] (1) 1 ~ 2mol FeCl 3 ·6H 2 Dissolve O in 25mL water to obtain solution A; dissolve 5.4 mol NaOH in 25mL water to obtain solution B; mix solution A and solution B, and react at 100°C for 24-96 hours to obtain precipitate A;

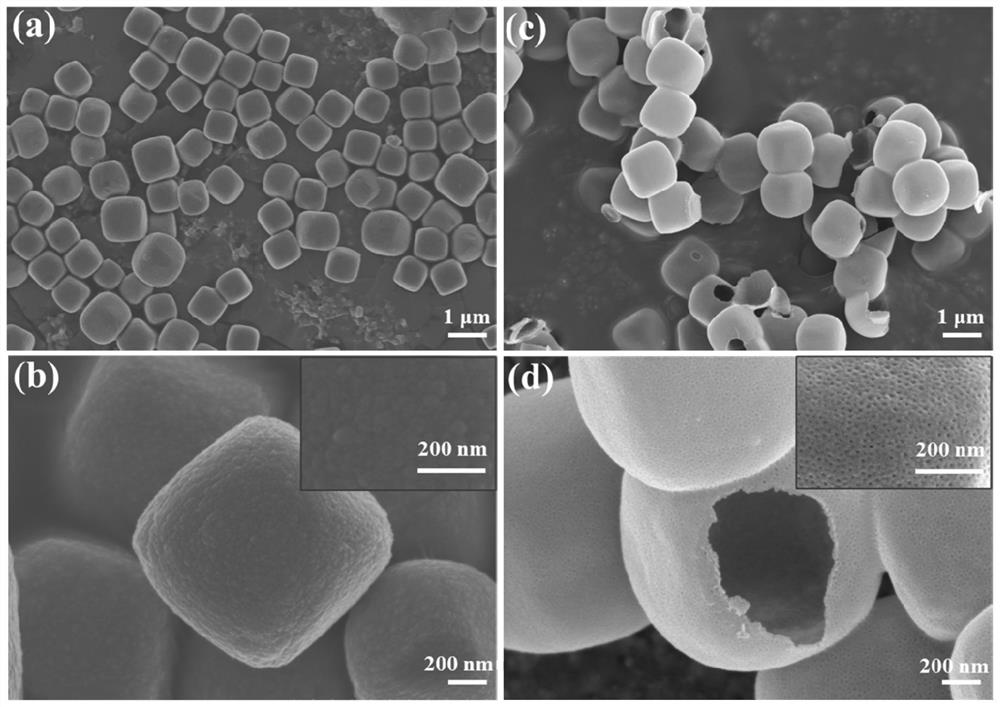

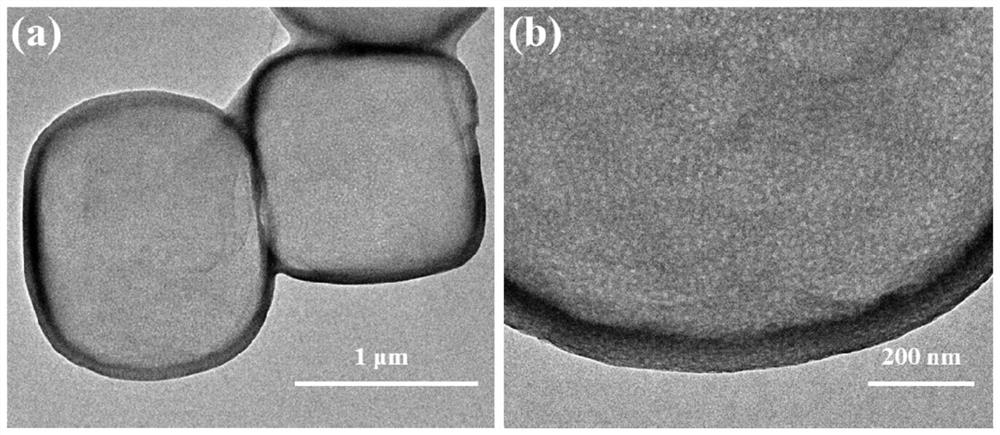

[0030] (2) Pour 0.2g~0.6g of precipitate A into a mixed solution of 10mL water and 10mL absolute ethanol, add 0.15g block copolymer F127, 0.15g dopamine hydrochloride, 0.5~1.5mL of 1,3, 5-Mesitylene, 0.4mL ammonia water, stirred and reacted at room temperature for 1-3 hours, washed and dried the product, and obtained brown precipitate B;

[0031] (3) Place the obtained precipitate B in a corundum porcelain boat and heat-treat it under an argon atmosphere at a temperature of 500-900°C and a heating rate of 2-5°C min -1 , The holding time is 1 to 4 hours.

[0032] (4) The obtained product was washed with dilute HCl,...

Embodiment 1

[0034] A method for preparing a mesoporous hollow carbon micro-cage material, comprising the following steps:

[0035] (1) 1mol FeCl 3 ·6H 2 O was dissolved in 25mL water to obtain solution A; 5.4mol NaOH was dissolved in 25mL water to obtain solution B; solution A and solution B were mixed and reacted at 100°C for 24 hours to obtain precipitate A;

[0036] (2) Pour 0.2g of precipitate A into a mixed solution of 10mL of water and 10mL of absolute ethanol, add 0.15g of block copolymer F127, 0.15g of dopamine hydrochloride, and 0.5mL of 1,3,5- mesitylene , 0.4mL ammonia water, stirred and reacted at room temperature for 1 hour, the product was washed and dried, and brown precipitate B was obtained;

[0037] (3) Place the obtained precipitate B in a corundum porcelain boat and heat-treat it under an argon atmosphere. The heat-treatment temperature is 500°C, and the heating rate is 2°C min -1 , holding time is 1h.

[0038] (4) The obtained product was washed with dilute HCl, c...

Embodiment 2

[0040]A method for preparing a mesoporous hollow carbon micro-cage material, comprising the following steps:

[0041] (1) 1mol FeCl 3 ·6H 2 O was dissolved in 25mL water to obtain solution A; 5.4mol NaOH was dissolved in 25mL water to obtain solution B; solution A and solution B were mixed and reacted at 100°C for 24 hours to obtain precipitate A;

[0042] (2) Pour 0.2g of precipitate A into a mixed solution of 10mL of water and 10mL of absolute ethanol, add 0.15g of block copolymer F127, 0.15g of dopamine hydrochloride, 1mL of 1,3,5-mesitylene, 0.4mL ammonia water, stirred and reacted at room temperature for 1 hour, the product was washed and dried, and brown precipitate B was obtained;

[0043] (3) Place the obtained precipitate B in a corundum porcelain boat and heat-treat it under an argon atmosphere. The heat-treatment temperature is 500°C, and the heating rate is 2°C min -1 , holding time is 1h.

[0044] (4) The obtained product was washed with dilute HCl, centrifuge...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com